Water cooler on-line backwashing method

A technology of backwashing and water coolers, applied in the direction of flushing, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as production and operation shutdown of water coolers, increase pressure and impact, ensure quality, and improve The effect of the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

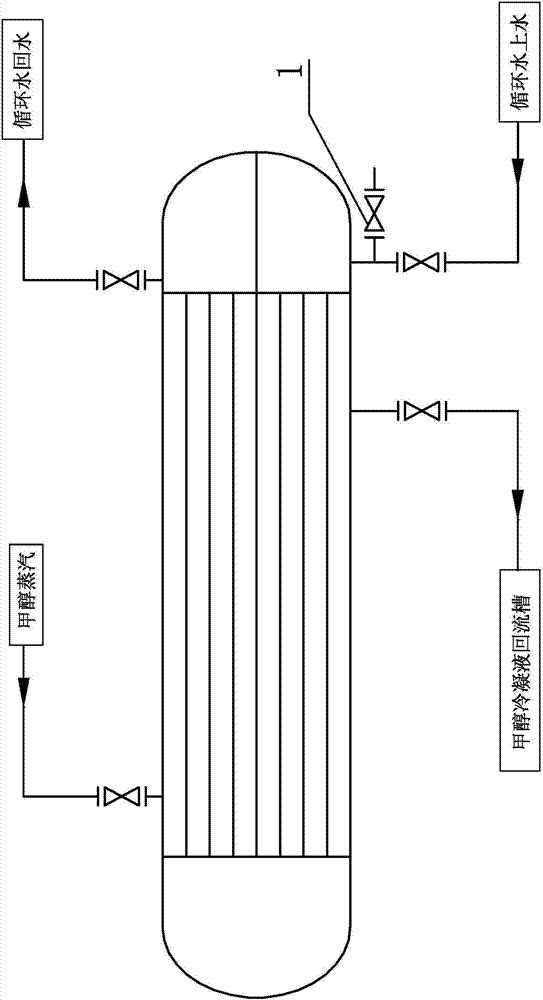

[0014] Specific implementation mode one: combine figure 1 Illustrate this embodiment, the method for online backwashing of a kind of water cooler described in this embodiment, it comprises concrete steps as follows:

[0015] Step 1. Simultaneously close the circulating water valve and the circulating water return valve of the water cooler;

[0016] Step 2. Drain the circulating water in the water cooler with a drainer. After N hours, open the circulating water return valve and put in water with 5% to 10% of the volume of the condenser tube of the water cooler, then close the circulating water return valve for 3 to 5 minutes and then Open the backwash drain gate valve for 110-30s, then close the backwash drain gate valve 1. Open the circulating water return valve for backwash; N is a natural number;

[0017] Step 3: Open the backwash drainage gate valve 1, and judge whether the water flowing out of the gate valve is clear, if not, perform step 3; if yes, end;

[0018] Wherein...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 This embodiment is described. This embodiment is a further limitation of the online backwashing method of the water cooler described in the first embodiment. The backwashing drainage gate valve 1 adopts a DN100 valve.

[0021] The methanol vapor is condensed into methanol condensate through the water cooler, the output end of the methanol condensate of the water cooler is connected to the input end of the methanol condensate recovery tank, and the input end of the methanol condensate recovery tank is set below the methanol condensate liquid level.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 This implementation mode is described. This implementation mode is a further limitation of the method for online backwashing of a water cooler described in the first specific implementation mode, where 1

[0023] The concrete process that the present invention applies is:

[0024] Install backwash drainage gate valve 1 on the circulating water pipeline behind the circulating water supply valve of the water cooler for backwash drainage of the water cooler.

[0025] During the backwashing operation, firstly close the circulating water supply valve and the circulating water return valve of the water cooler. Drain the circulating water in the water cooler with a drainer.

[0026] Methanol vapor is normally fed into the water cooler to heat the impurities on the tube wall of the water cooler. After heating for 1 to 3 hours, the circulating water return valve is opened, and the water entering the water cooler tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com