Lead arc-forming method for manufacturing salient point by utilizing laser

A lead and arc forming technology, used in manufacturing tools, laser welding equipment, semiconductor/solid-state device manufacturing, etc., can solve problems such as reducing efficiency and yield, affecting chip consistency, and inconsistent lead forming, achieving shortened time, Reduce lead damage and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

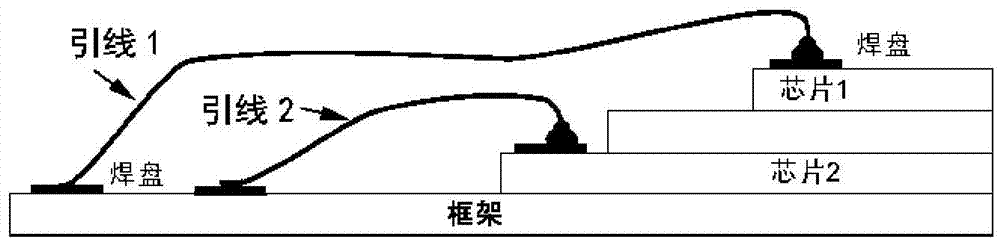

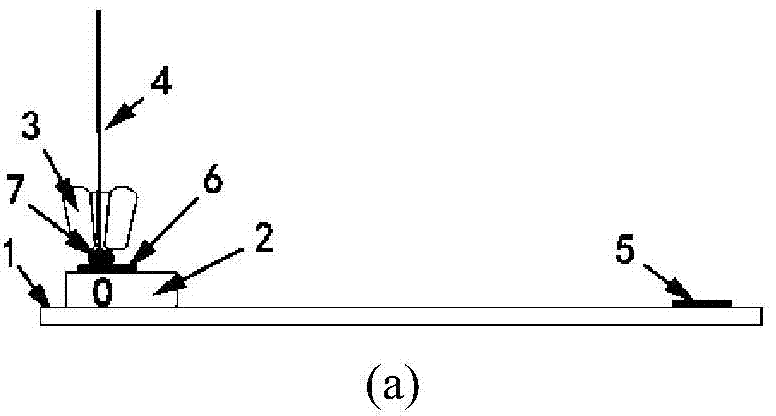

[0045] The method of the present invention is used to form a large-span low-arc lead, such as image 3 As shown, the specific method is:

[0046] Step 1: Form the first solder joint at the midpoint position O of the chip pad (6), such as image 3 as shown in (a);

[0047] Step 2: The rivet rises vertically to point E, releasing a section of lead wire OE, and the length of OE is 7500 microns;

[0048] Step 3: Use the left laser set on the left side of the rivet to irradiate points B and D of the lead from the left side of the rivet respectively, where the OB length is 3000 microns and the OD length is 6750 microns, forming two thermoplastic regions with Large deformation on the left and small deformation on the right form two inflection points protruding to the right; similarly, through the right laser set on the right side of the rivet, the points A and C of the lead wire are irradiated from the right side of the rivet. Among them, the length of OA is 100 microns, and the l...

example 2

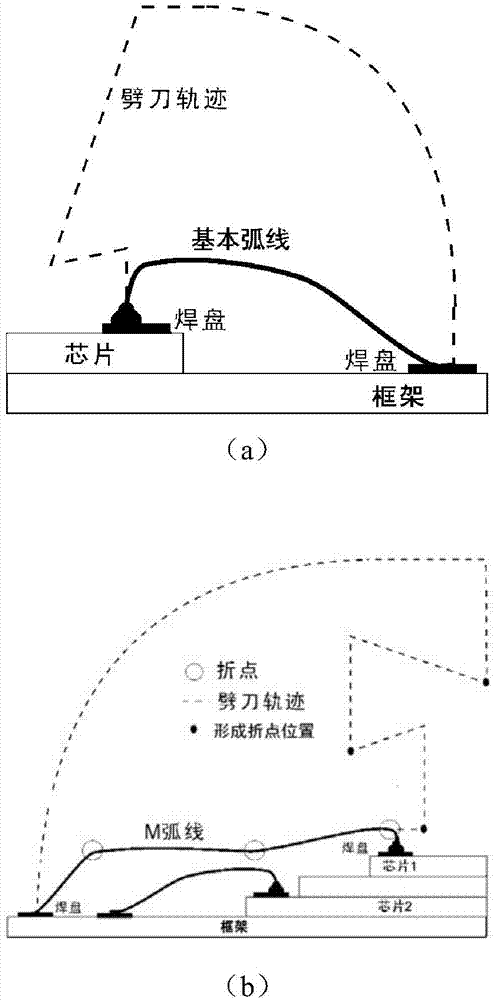

[0051] Adopt the method of the present invention to form basic leads, such as Figure 4 As shown, the specific method is:

[0052] Step 1: Form the first solder joint 7 at the center point position O of the chip pad 6, such as Figure 4 (a);

[0053] Step 2: The rivet 5 rises vertically to point E, and releases a section of lead wire 6, the length of which is OE, and the length of OE is 1300 microns;

[0054] Step 3: Use the left laser set on the left side of the rivet to irradiate the point A of the lead wire from the left side of the rivet. The length of the OA is 150 microns to form a thermoplastic zone, which has the characteristics of large deformation on the right and small deformation on the left to form 1 vertices that protrude to the left, such as Figure 4 as shown in (b);

[0055] Step 4: Take point O as the center point, and the distance |OF| between point O and point F is the minor axis of the ellipse. The length of OF is 1000 microns, and the major axis of th...

example 3

[0057] The forming method of the large-span n-arc lead mentioned in the present invention will be based on Figure 5 to describe. The specific method is:

[0058] Step 1: Form the first solder joint at the midpoint position O of the chip pad (6), such as Figure 5 as shown in (a);

[0059] Step 2: The rivet 5 rises vertically to point E, and releases a section of lead wire 6, the length of which is OE, and the length of OE is 5000 microns;

[0060] Step 3: Irradiate point A and point D of the lead wire from the left side of the rivet with the left laser set on the left side of the rivet respectively, where the OA length is 150 microns and the OD length is 4000 microns, each forming a thermoplastic zone , which has the characteristics of large deformation on the right side and small deformation on the left side, so as to form two vertices protruding to the left, such as Figure 5 as shown in (b);

[0061] Step 4: Take point O as the center point, and the distance |OF| betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com