Method and apparatus for particle separation

A particle and adjusting device technology, which is applied in solid separation, wet separation, and cyclone axial reversal devices, etc., can solve the problems of complex devices, low-quality separation, and unfavorable connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

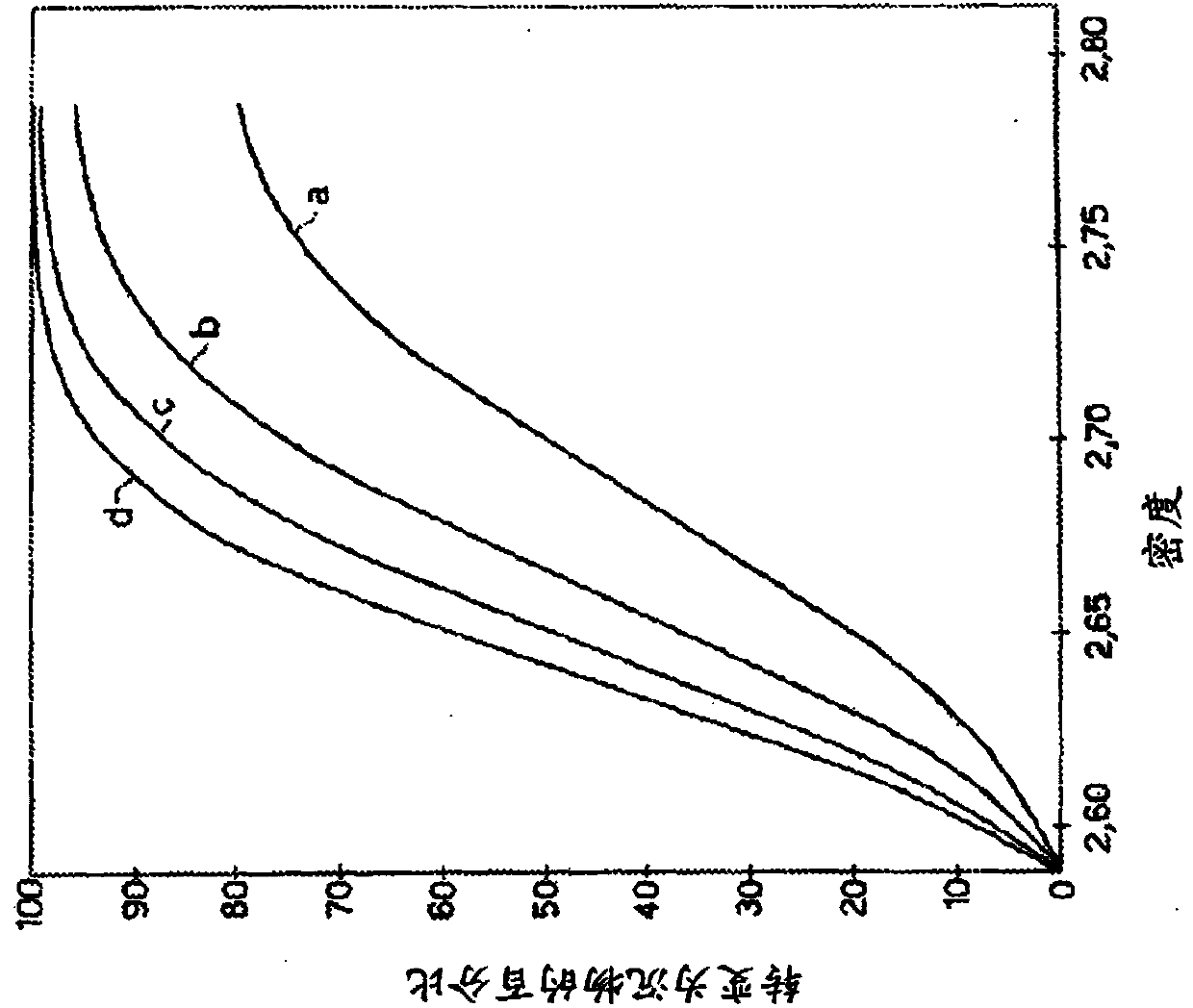

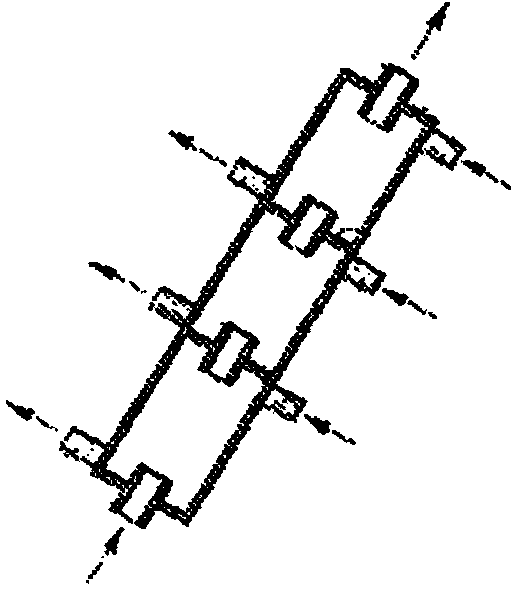

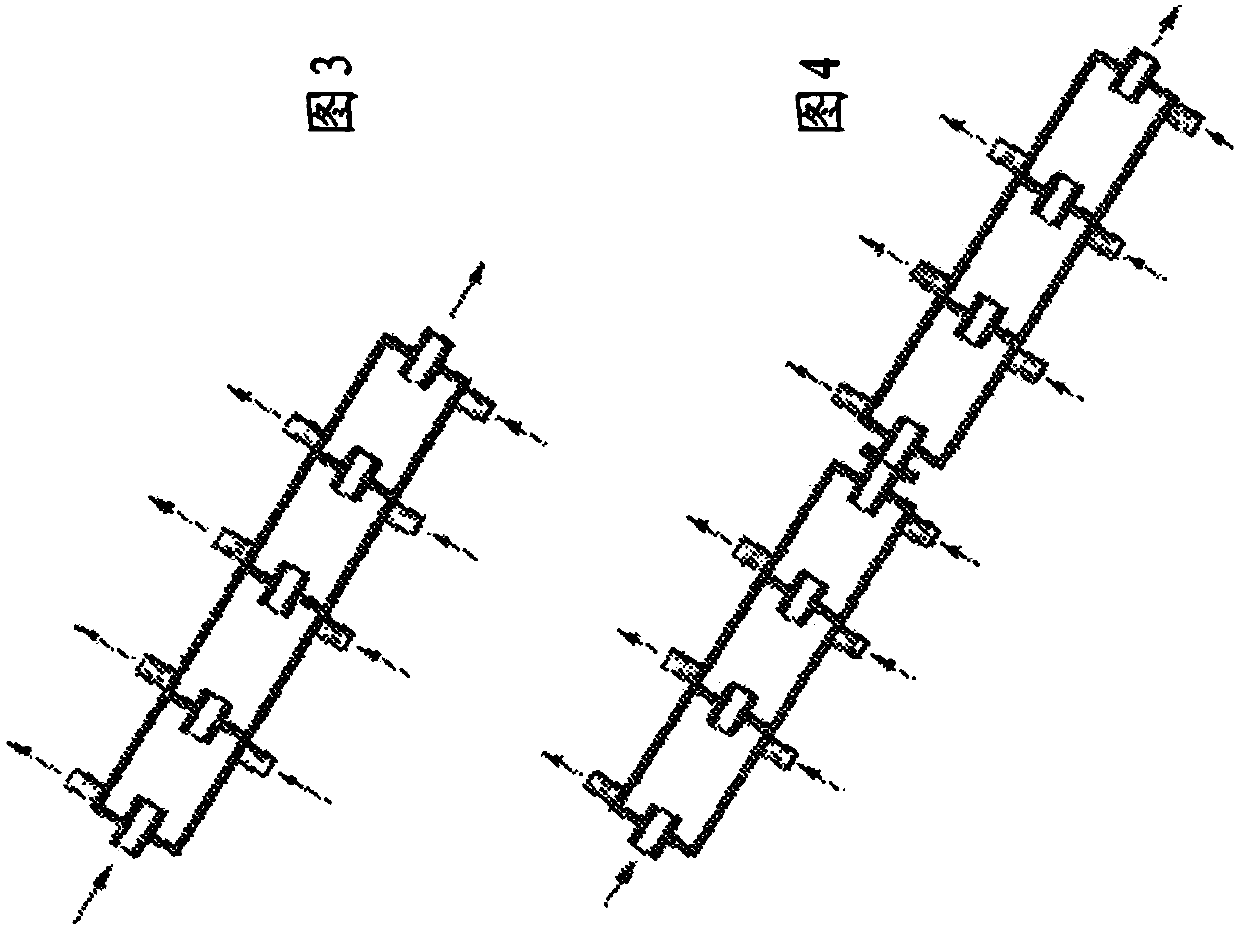

[0030] With reference to the drawings listed above and in particular Figures 5 to 10 , showing different embodiments of the separation device according to the invention; the first of these embodiments is at Figure 5 is denoted by 1 as a whole and it comprises two separation stages, wherein the first separation stage consists of a cyclone separator 2 and the second separation stage is a cylindrical separator 3 .

[0031] Since these types of separators are known per se, in this specification reference will only be made to those parts which are necessary for understanding the invention, other more detailed descriptions are referred to prior art, scientific literature and patents on the subject Published documents; among such published documents, in addition to the above-mentioned documents (IT1152915 and GB2164589), it is also pointed out that the patent published documents GB530309 or GB542988 related to cyclone separators are included.

[0032] Separator 1 is used in partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com