Acoustic sensor and method for manufacturing same

A sound sensor and substrate technology, applied in the direction of sensors, sensor parts, electrostatic transducer microphones, etc., can solve the problems of the decrease of the sensitivity of the sound sensor, the deterioration of the sensitivity characteristics, the leakage of the space in the box, etc., to improve the fixing strength and stability. , The effect of preventing the deterioration of the sensitivity characteristics and the increase of the acoustic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

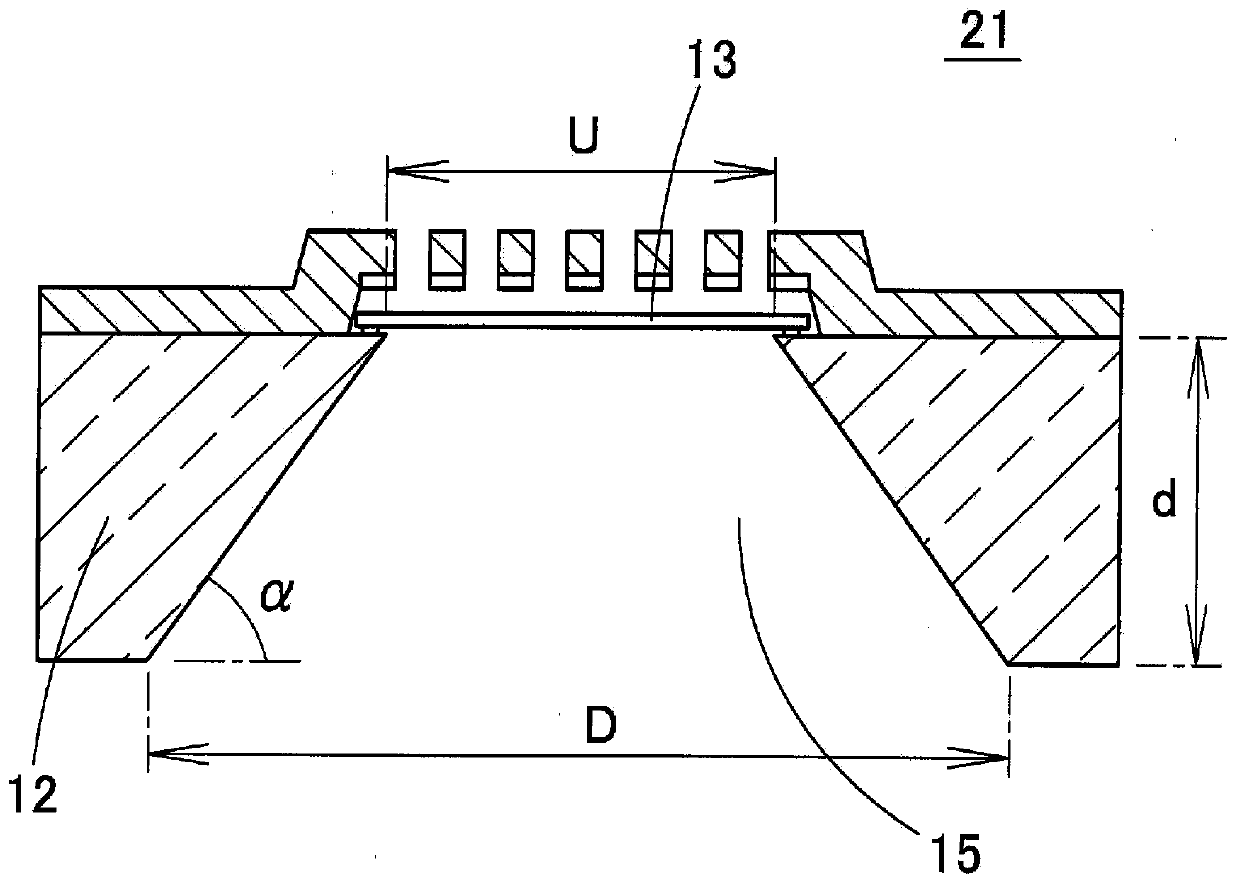

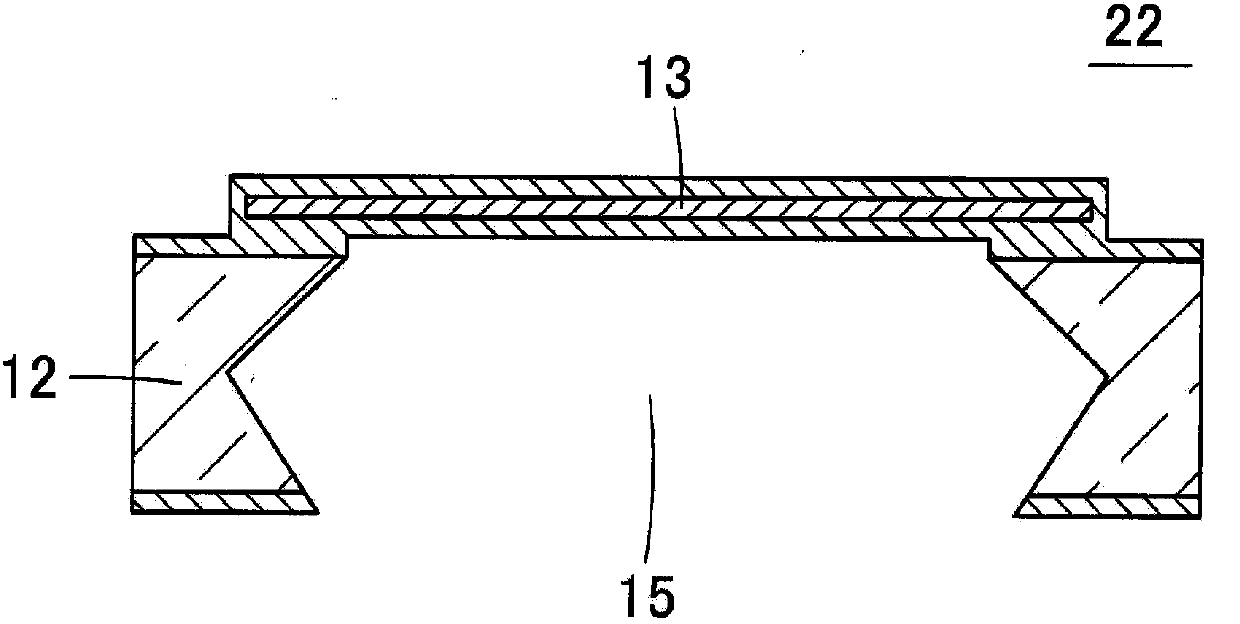

[0102] (Acoustic sensor of the first embodiment)

[0103] Figure 10 It is a sectional view showing the structure of the acoustic sensor 41 according to the first embodiment of the present invention. The acoustic sensor 41 has a substrate 42 , a film-shaped diaphragm 43 , a back plate 45 , and fixed electrodes 46 . The substrate 42 is a (100)-plane Si substrate whose front and back are (100) planes. A cavity 44 is formed in the substrate 42 to penetrate the front and back surfaces by etching from the back side. The cavity 44 has wall surfaces in four directions, and when viewed from a direction perpendicular to the surface of the substrate 42, as Figure 11 As shown, the cavity 44 has a rectangular shape with each side facing the (110) direction or a direction equivalent to the (110) direction.

[0104] Figure 10 shows the sound sensor 41 along the Figure 11 The cross-section of the K-K line. Each wall surface of the cavity 44 includes a first slope 47 a and a second ...

no. 2 approach )

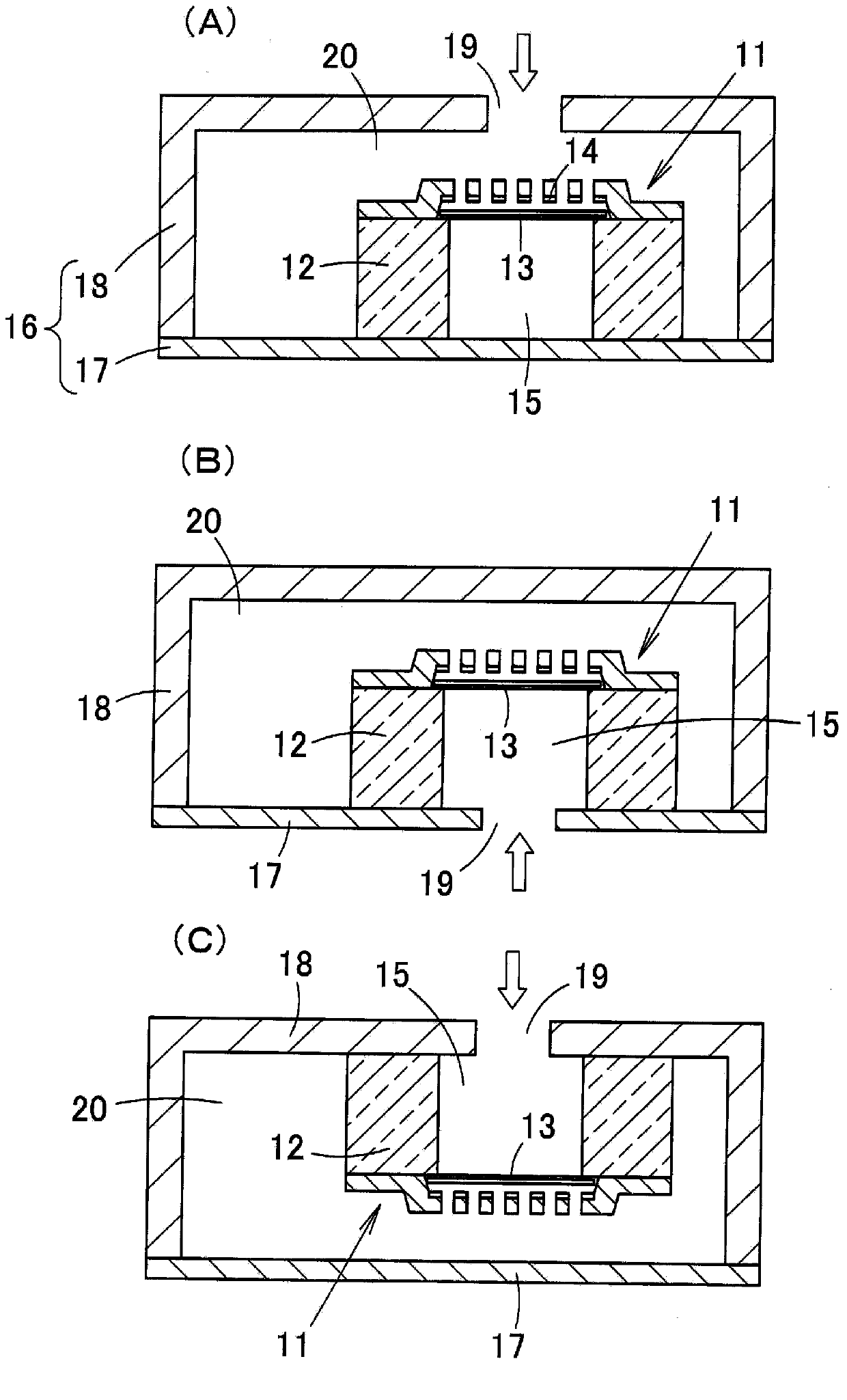

[0135] Figure 19 (A) is a sectional view of the acoustic sensor 81 according to the second embodiment of the present invention. In this acoustic sensor 81 , the heights H3 and H4 of the nodes P are different between the opposing wall surfaces of the cavity 44 , and the cross-sectional shapes of the wall surfaces are different from each other. At this time, the height H4 of one node P is larger than 1 / 2 of the thickness of the substrate 42, but the height H3 of the other node P can be larger than 1 / 2 of the thickness of the substrate 42 or smaller than the thickness of the substrate 42. half of the thickness.

[0136] In order to form such an asymmetric cavity 44, in the method of manufacturing the acoustic sensor described in the first embodiment, when the through-hole 76 is opened in the substrate 42 by dry etching, as Figure 19 As shown in (B) in (B), the center of the through hole 76 may be shifted from the center of the sacrificial layer 71 in the horizontal direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com