Laser lap welding gap detecting system and laser lap welding gap detecting method based on molten pool image visual sensing

A technology of image vision and detection method, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as not considering the laser welding situation, achieve good real-time monitoring effect, low power consumption, and improve welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

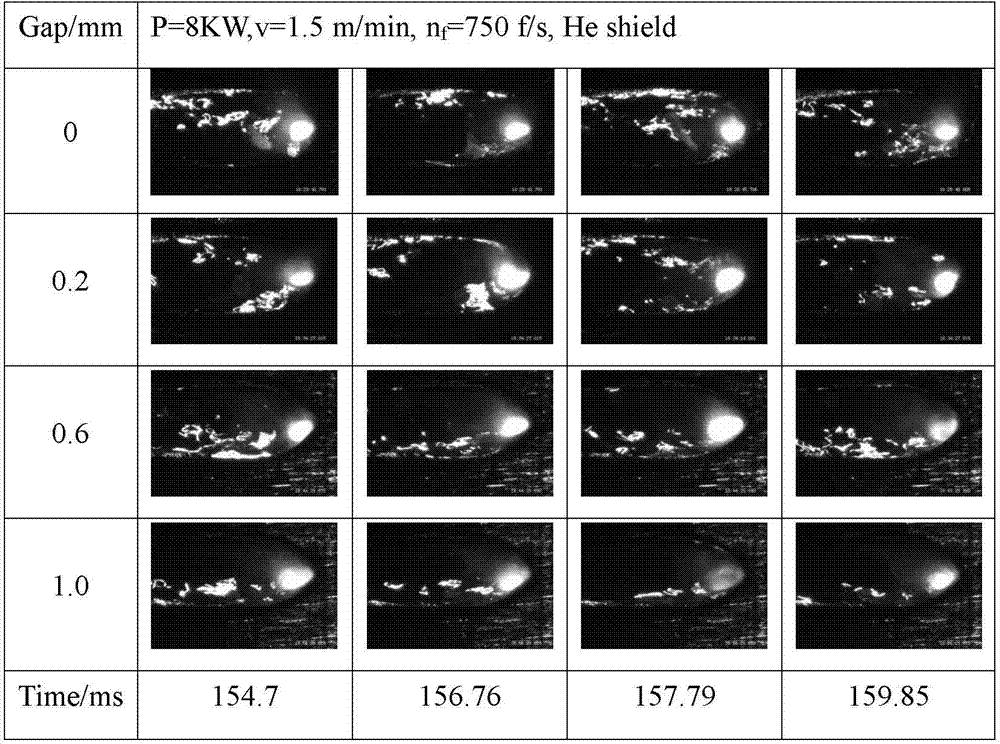

[0036] Example 1 Detection of the relationship between gap volume and molten pool parameters

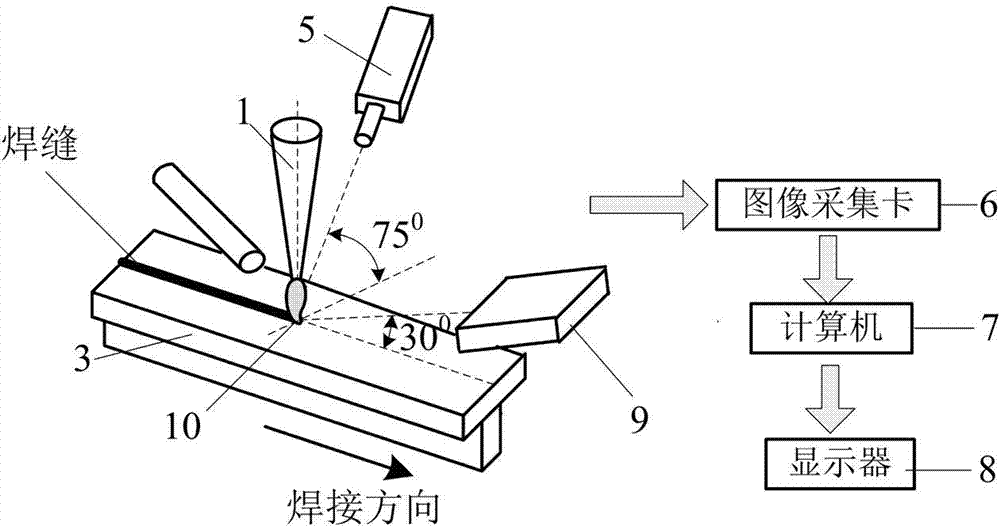

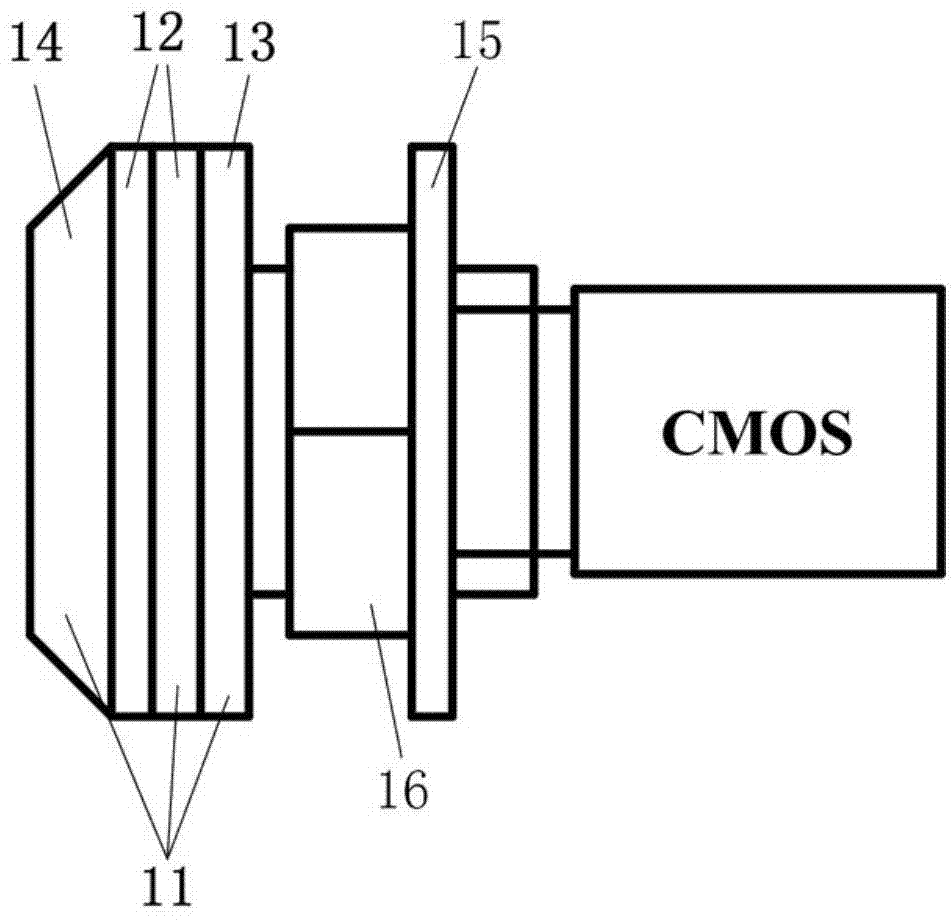

[0037] The detection method of the laser welded T-shaped lap joint gap based on molten pool image visual sensing in the present embodiment and embodiment 2 adopts the following methods: figure 1 and figure 2 The visual sensing system shown includes: a CMOS camera (5) with LinLog photosensitive technology, a filter system (11), an image acquisition card (6), a computer (7), and a display (8), wherein the computer ( 7) It is a dual-computer system composed of the image acquisition of the main computer and the image processing of the slave computer equipped with the Labview image processing platform. The main computer collects the image information of the welding area and sends it to the monitor (8) for real-time display, and the slave computer performs image processing and calculation, and Feedback to the main computer in time for image comparison and analysis to find out the corresp...

Embodiment 2

[0054] Example 2 The actual detection of the gap amount of the laser welded T-shaped lap joint

[0055] Adopt the detection system and method of embodiment 1, and utilize the relation between the laser welded T-type lap joint gap and molten pool parameter that it obtains, through to the real-time observation of molten pool image in welding process and orifice area and molten pool For the calculation of width, length and area, the following two groups of laser welded T-shaped lap joints are gap tested, and the test results are as follows: Figure 13 shown.

[0056] The monitoring results of the first group a are as follows: the length of the molten pool is 9.6mm, the area of the molten pool is 44323 Pixel, and the orifice area is 2665. Through the comprehensive analysis of the above data and the dynamic characteristics of the molten pool and the orifice, it can be known that the gap in the welding process is about 0.2mm. From Figure 13 From the cross-section of the correspo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com