A dual transverse magnetic field magnetron microbeam plasma arc welding seam tracking method for ultra-thin-walled tube welding

A technology of transverse magnetic field and plasma arc, applied in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not seeing the performance of ultra-thin-walled tubes, save space and materials, improve weld structure and performance, Improved results for weld seam formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better express the technical solutions and advantages of the entire invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] see figure 1 , the application scenario of the present invention is an ultra-thin-walled pipe that has not yet been welded. At this time, there is a gap with a very narrow width on the upper semi-cylindrical surface of the ultra-thin-walled tube, and a weld seam will be formed at the gap during the welding process. The method proposed by the invention is used to realize the welding seam tracking of ultra-thin-wall pipe welding.

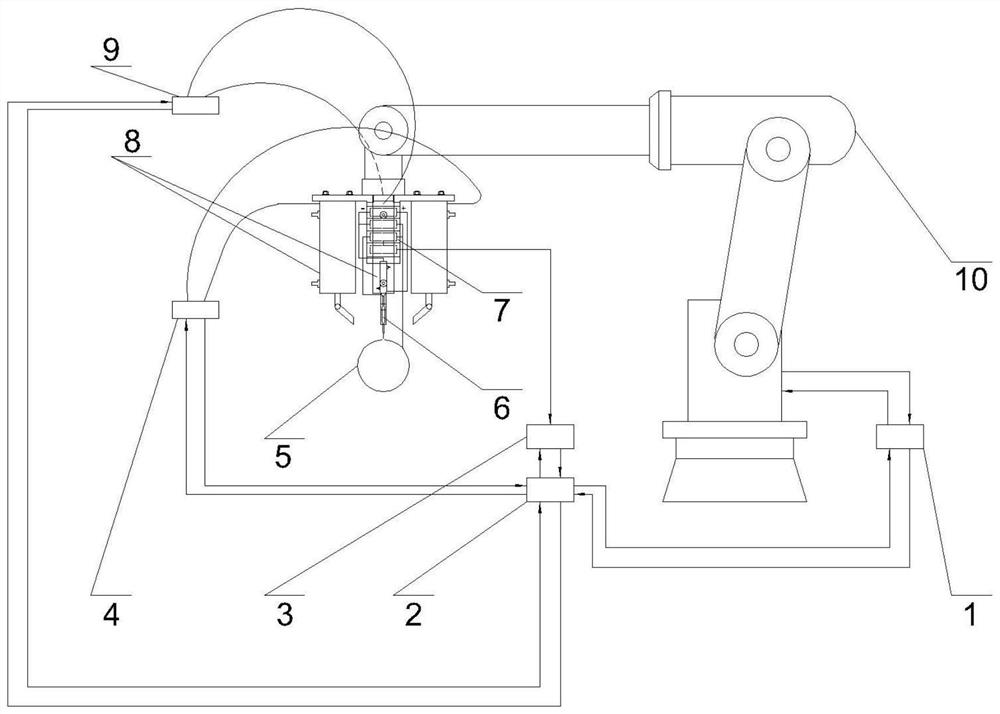

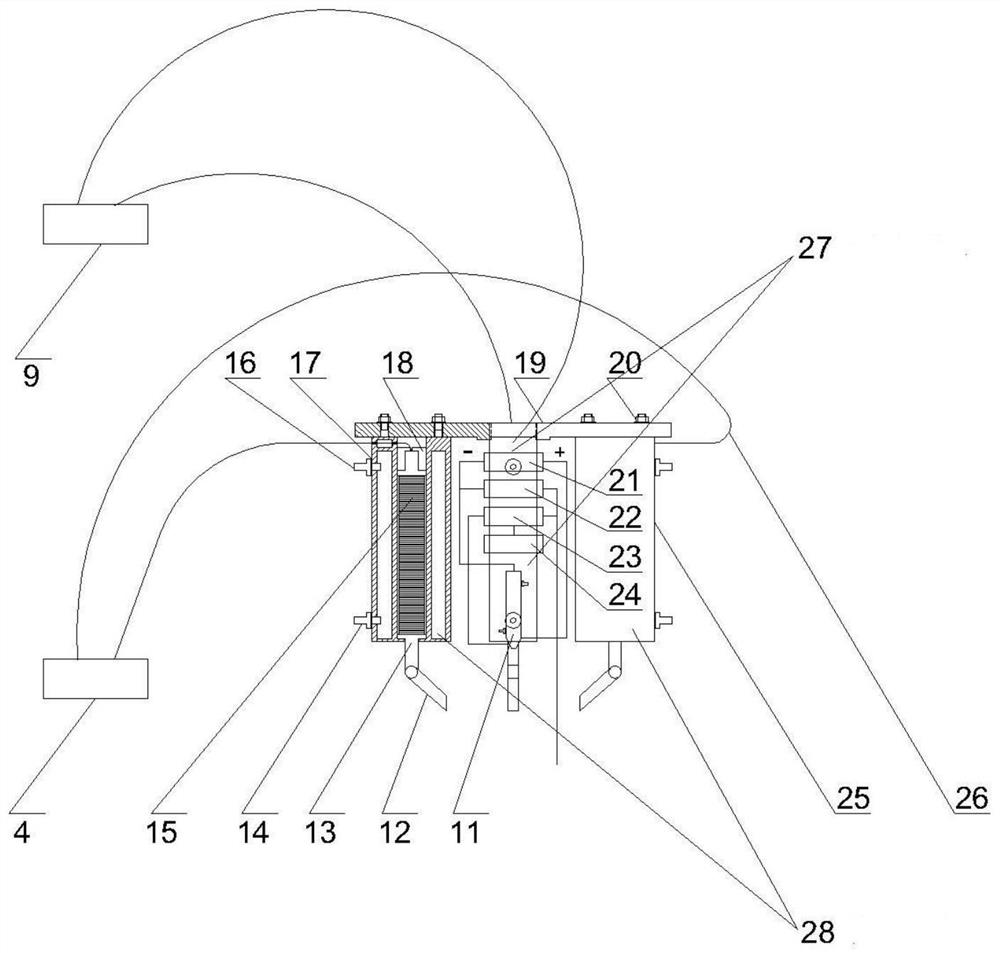

[0028] The present invention is a double transverse magnetic field magnetron micro-beam plasma arc welding seam tracking method for ultra-thin-wall pipe welding. The welding seam tracking system adopted in the method is as follows: figure 2 As shown, it mainly includes a double transverse magnetic field magnetron micro-beam plasma arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com