Non-motor vehicle provided with reciprocating type seat

A non-motor vehicle, reciprocating technology, which is applied in the directions of vehicle components, rider driving, transportation and packaging, etc., can solve the problems of increased frictional resistance and effort, and achieve the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

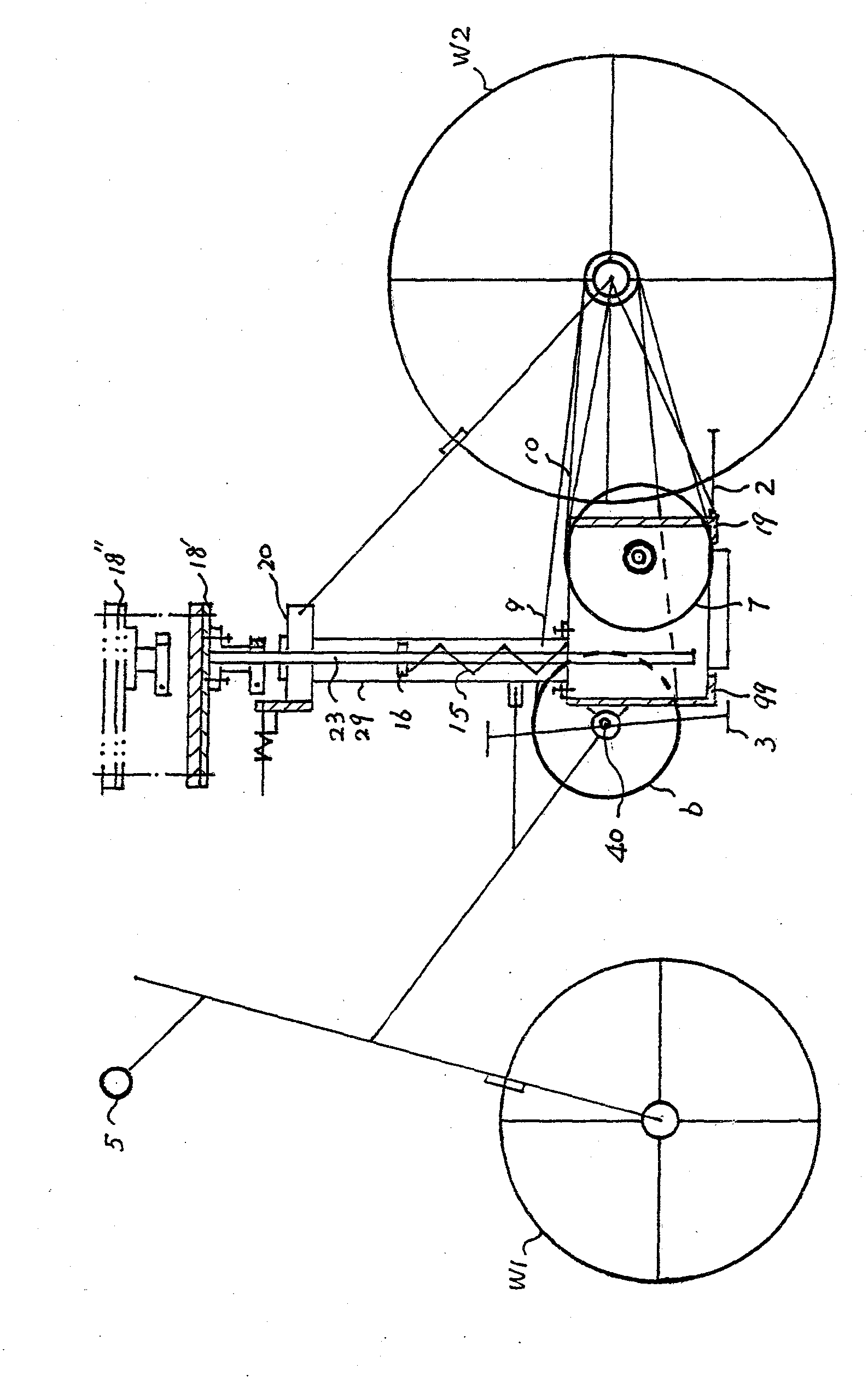

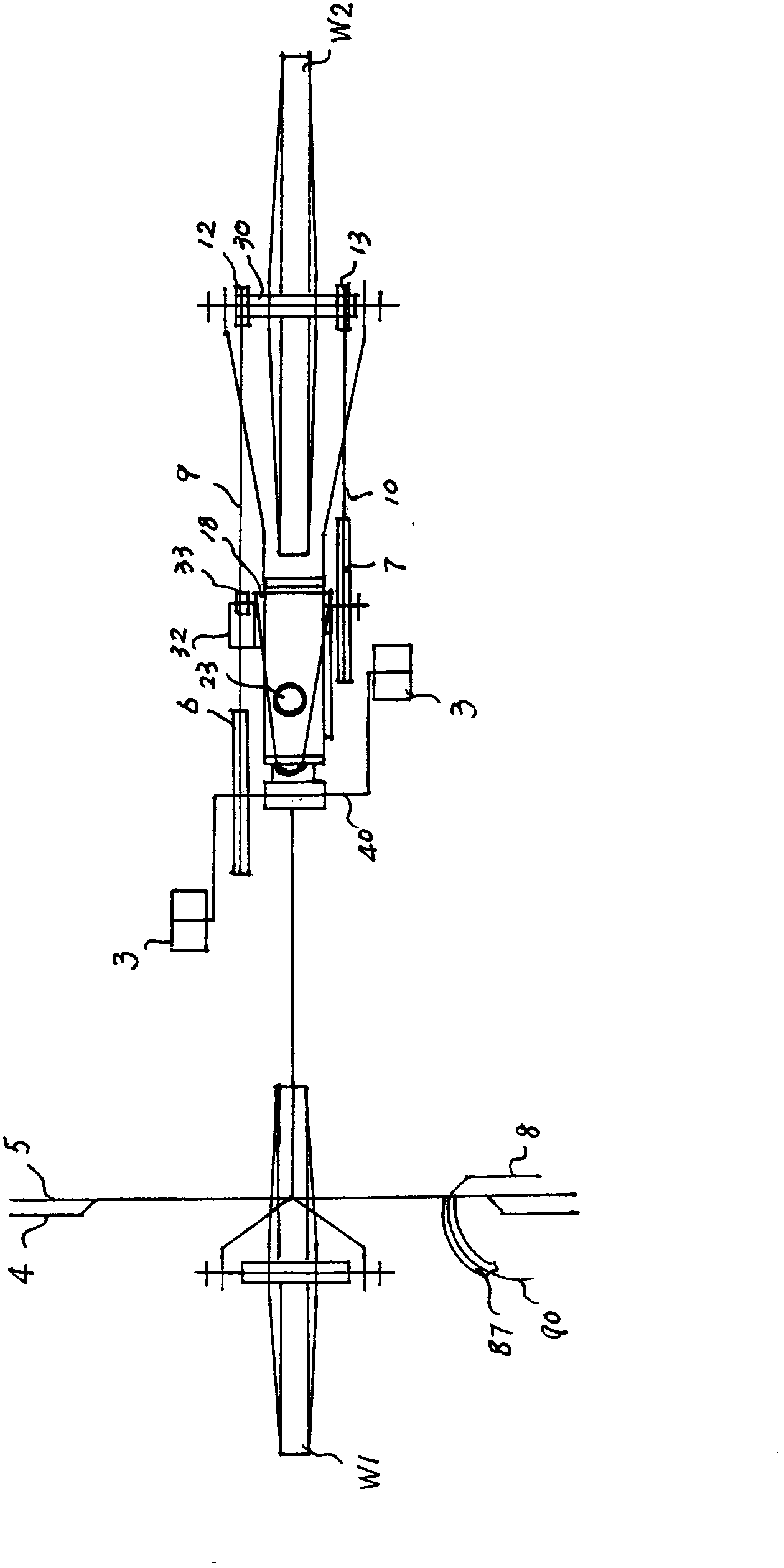

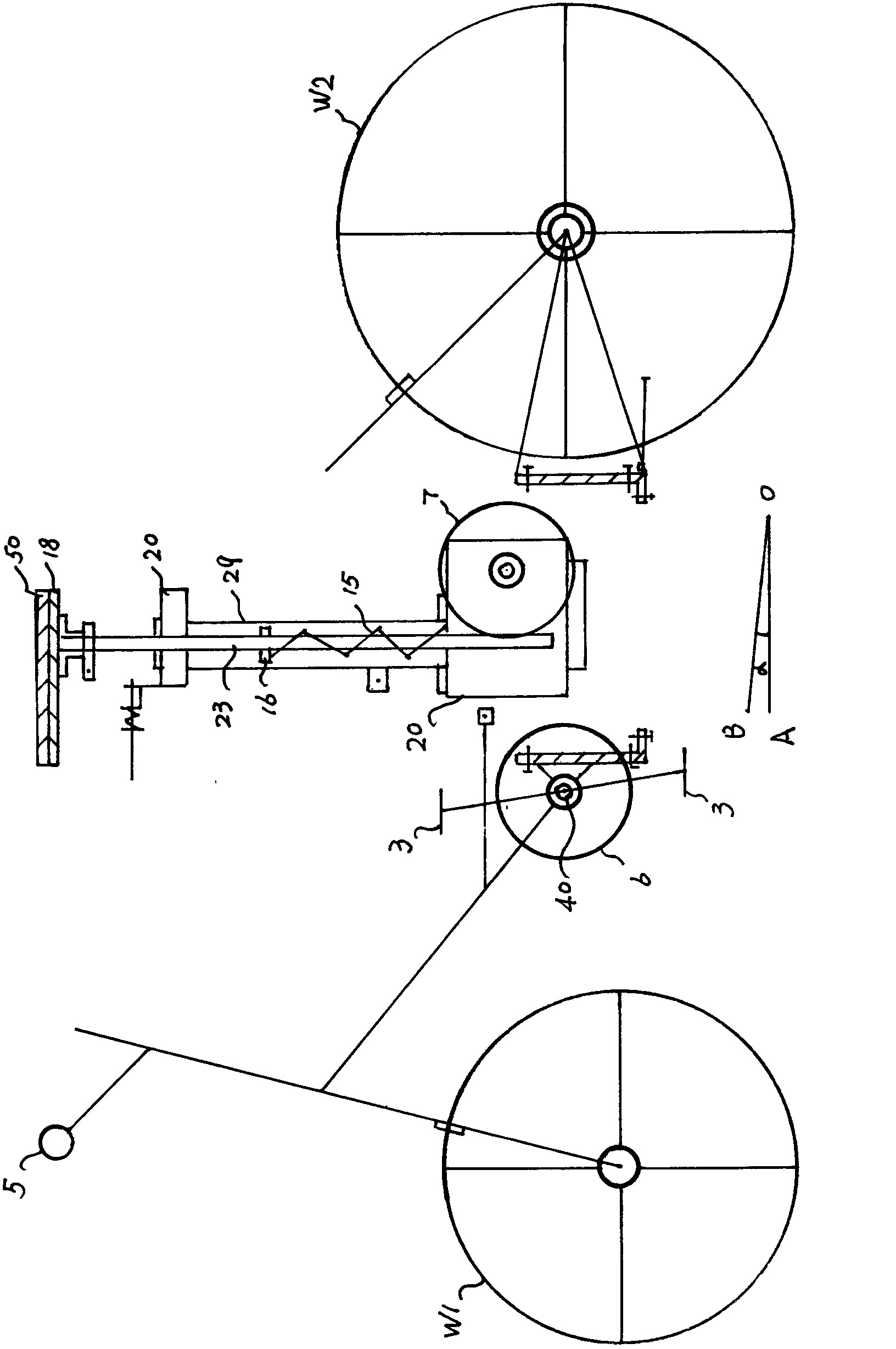

[0038] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0039] In the picture: W1, passive wheel, W2, driving wheel, W3, driving wheel, 1, bending surface, 2, support foot, 3, footboard, 4, brake lever, 5, handle, 6, main chain Wheel, 7, auxiliary sprocket, 8, clutch lever, 9, main chain, 10, auxiliary chain, 11, tensioner splint, 12, main flywheel, 13, auxiliary flywheel, 14, screw pin shaft, 15, spring , 16, spring backing, 17, gear box, 18, seat stool, 18′, seat stool when descending, 18″, seat stool when rising, 19, rear frame, 20, rail box, 21, round hole, 22, Fastening ring, 23, guide shaft, 24, rack, 25, flat strip, 26, shock-proof ring, 27, front support backing, 28, screw, 29, middle frame, 30, hub, 31, rolling pulley, 32. Tensioner splint, 33, tension gear, 34, spring pin, 35, nut, 36, bracket seat, 37, pulley shaft, 38, bushing, 39, steel ball, 40, bottom bracket, 41, lock seat , 42, lock shaft, 43, internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com