Gravity friction brake for high-rise escaping machine

A friction gate and gravity technology, applied in the field of gravity friction gate, can solve the problems of inability to transfer personnel in batches, slow transfer speed, operational skills and physical fitness requirements of the transferred personnel, etc. The effect of easy size control and even distribution of friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

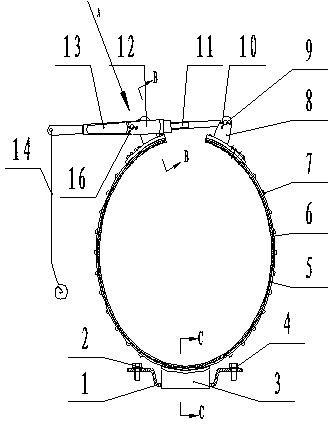

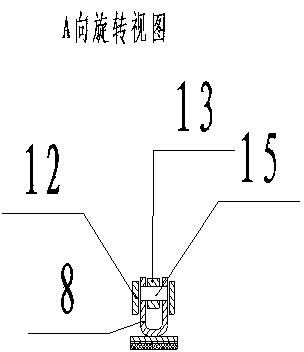

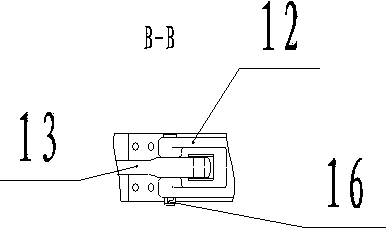

[0017] see figure 1 , figure 2 , image 3 , Figure 4 , the positioning plate 1 is fixed on the base of the high-rise peach life machine through the bolt 2 and the spring washer 4, the T-shaped plate 3 on the gravity friction brake is set in the rectangular hole of the positioning plate 1, so that the entire gravity friction brake is positioned, and at the same time, the gravity friction brake During the braking process, prevent the turning circle from slipping and avoid ineffective braking.

[0018] The lower part of the brake steel belt 5 is welded with a T-shaped plate 3, which is positioned by the positioning plate 1, and the inner side is equipped with an asbestos belt 6, which is riveted on the steel belt by rivets 7, and two brackets 8 are welded at the upper symmetrical opening. Bracket is the support member of the braking control mechanism of fixing whole gravity friction brake.

[0019] One end of the joint screw 11 is connected and fixed with the bracket 8 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com