Cleaning robot

A cleaning robot and cleaning technology, which is applied in the field of cleaning robots to achieve the effects of avoiding leakage, uniform distribution of friction, and avoiding slippage and deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

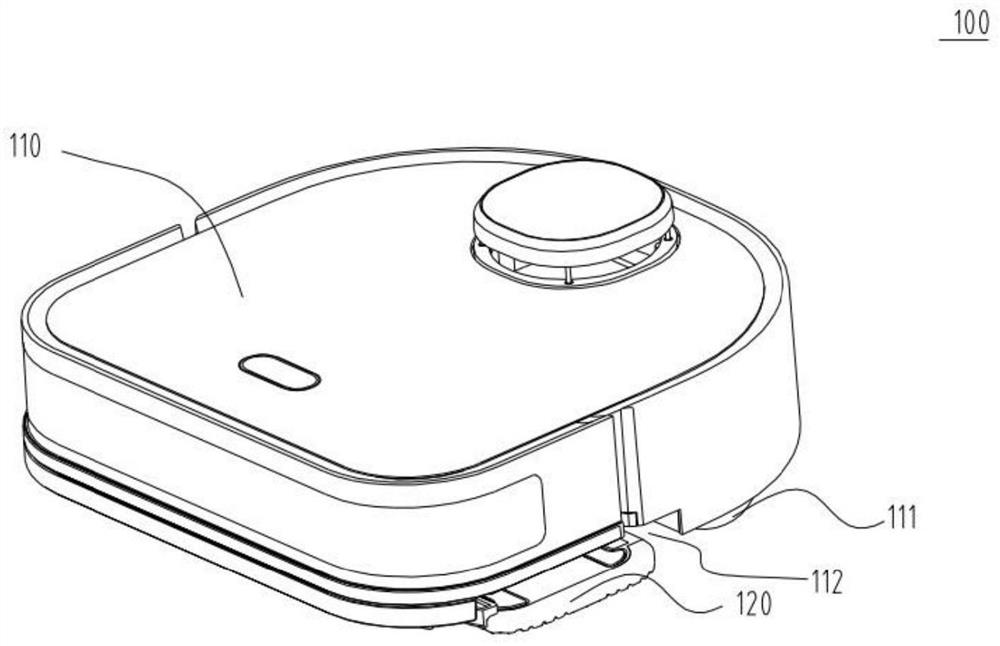

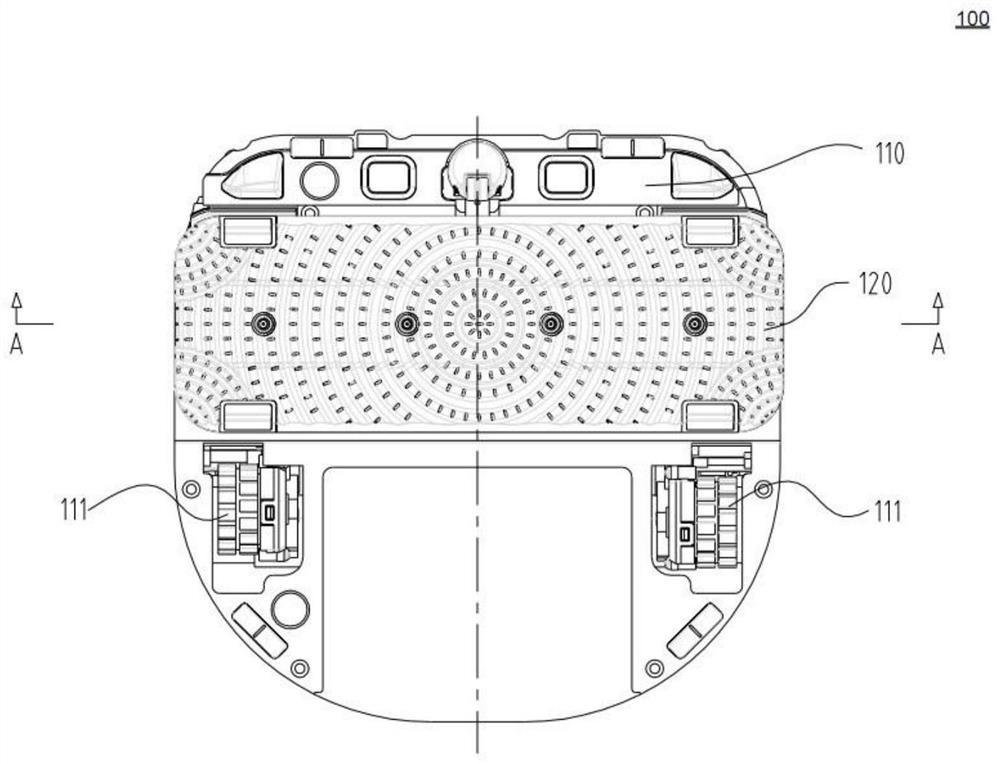

[0049] Such as Figure 1 to Figure 7 It is the first embodiment of the present invention. refer to figure 1 and Figure 5 , the cleaning robot 100 includes a body 110 . The walking module supports the body 110 and drives the cleaning robot 100 to move on the working surface, and includes a driving motor and multiple walking components. In this embodiment, the walking component optionally includes two driving wheels 111 . The control module has an integrated circuit board for connecting and controlling various functional modules, and can control the cleaning robot 100 to walk in a preset working area, and control the cleaning module 120 to perform cleaning tasks. A cavity 112 is provided at the bottom of the fuselage 110 , and the opening direction of the cavity 112 faces the working surface, at least partially accommodating the cleaning module 120 from above the cleaning module 120 . The cleaning module 120 is used to clean the working surface. The cleaning module 120 incl...

Embodiment 2

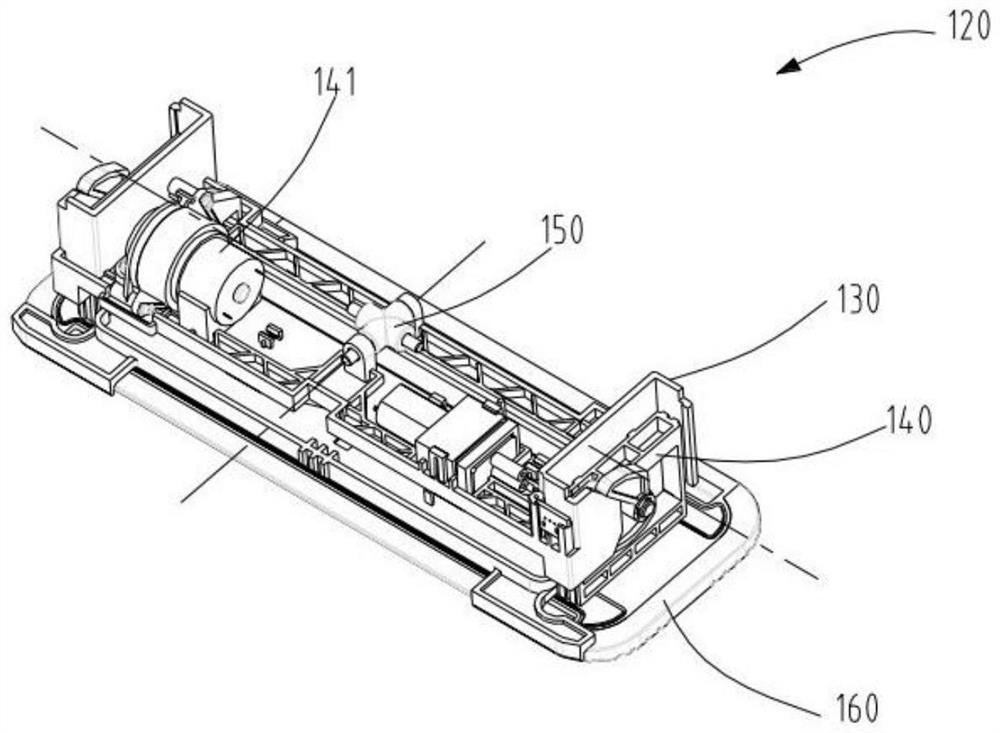

[0056] The difference between the second embodiment and the first embodiment lies in that the structure of the cleaning module 120 and the structure of the pivoting part 150 are different. refer to Figure 8 , the cleaning module 120 includes a mopping floor 160 . The lifting mechanism 140 that is responsible for lifting and mopping the floor is fixedly connected with the bottom of the fuselage 110 to become one. The lifting mechanism includes a lifting motor 141 and a transmission mechanism. The bottom can move up and down relative to the bottom of the fuselage. The lifting mechanism 140 also includes a receiving plate 143 for installing the mopping floor 160 , which is fixedly connected with the bottom of the lifting frame and located at the top of the cavity 112 . The receiving plate 143 drives the mopping floor 160 to move up and down through the transmission mechanism under the drive of the lifting motor 141 of the lifting mechanism 140 . The receiving plate 143 is det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com