Special forklift used for aluminum ingot continuous casting production line

A casting production line, forklift technology, applied in the direction of lifting devices, etc., can solve the problems of large errors and difficult to guarantee accuracy, and achieve the effects of increasing costs, improving production efficiency and intelligence

Inactive Publication Date: 2014-01-15

LANZHOU UNIVERSITY OF TECHNOLOGY +1

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This online automatic weighing method uses a set of pneumatic lifting device to lift the stack of aluminum ingots for weighing. It is a dynamic weighing method with large errors and difficult to guarantee accuracy. The obtained data can only be used for internal production management. , the second weighing must be carried out when entering storage or trading

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

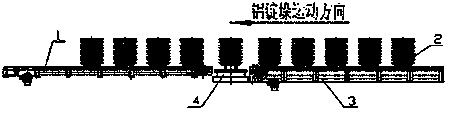

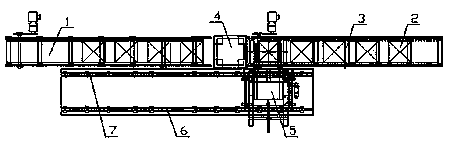

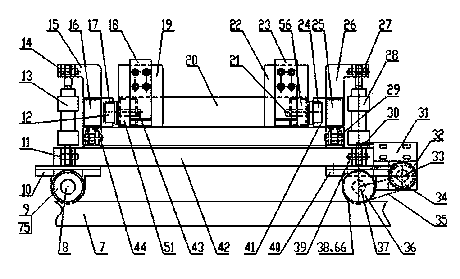

Disclosed is a special forklift used for an aluminum ingot continuous casting production line. An online dynamic weighing method of an existing aluminum ingot continuous casting production line is changed to an online static weighing method, and an existing automatic online weigher arranged inside a finished product conveyor is changed to an external automatic online weigher. A finished aluminum ingot stack (2) is conveyed to a transfer position through a primary finished product conveying machine (3), then the finished aluminum ingot stack (2) is transferred to an electronic balance (4) through the special forklift (5) to be weighed, after being weighed, the finished aluminum ingot stack (2) is transferred to a secondary finished product conveying machine (1) through the special forklift (5), and at last, the finished aluminum ingot stack (2) is conveyed to a finished product storehouse through the secondary finished product conveying machine (1). The special forklift (5) returns to the original position to repeat a next cycle.

Description

technical field [0001] The invention relates to special equipment for an aluminum ingot continuous casting production line. Background technique [0002] The weighing method of the finished aluminum ingot stack in the existing aluminum ingot continuous casting production line is online automatic weighing: the electronic scale is designed inside the frame of the finished product conveyor, and the electronic scale and the finished aluminum ingot stack are lifted by a set of pneumatic lifting devices to realize Online automatic weighing. This online automatic weighing method uses a set of pneumatic lifting device to lift the stack of aluminum ingots for weighing. It is a dynamic weighing method with large errors and difficult to guarantee accuracy. The obtained data can only be used for internal production management. , the second weighing must be carried out when storing or trading. Contents of the invention The purpose of the present invention is to provide a special fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B66F9/06B66F9/075B66F9/12B66F9/22

Inventor 史新郭俊峰魏兴春冯瑞成罗德春任丽娜刘军王鹏赵伟平段占宁芮执元赵俊天

Owner LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com