Preparation method of demulsifying agent

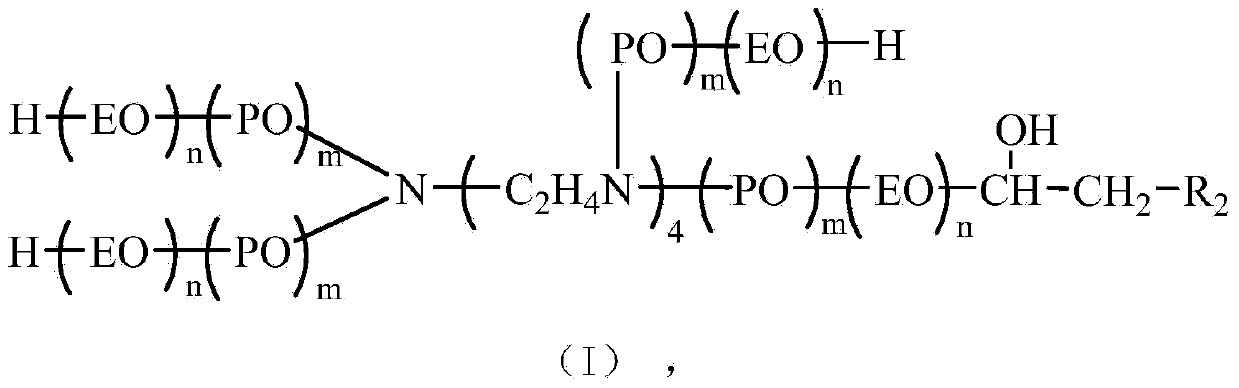

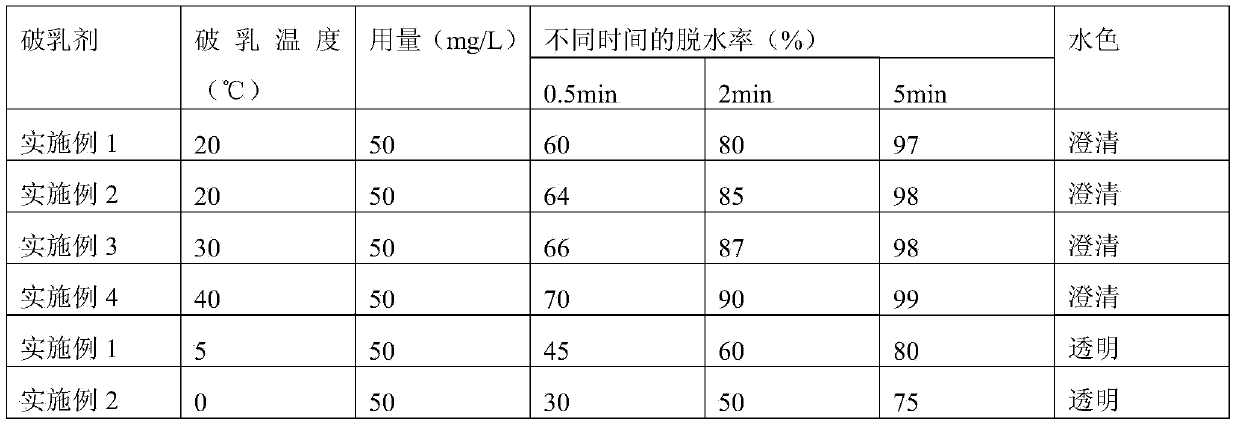

A technology of demulsifier and solvent, applied in the field of preparation of demulsifier, can solve the problem of high demulsification temperature, and achieve the effects of low demulsification temperature, good demulsification effect and reduction of processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of demulsifier, the steps are as follows:

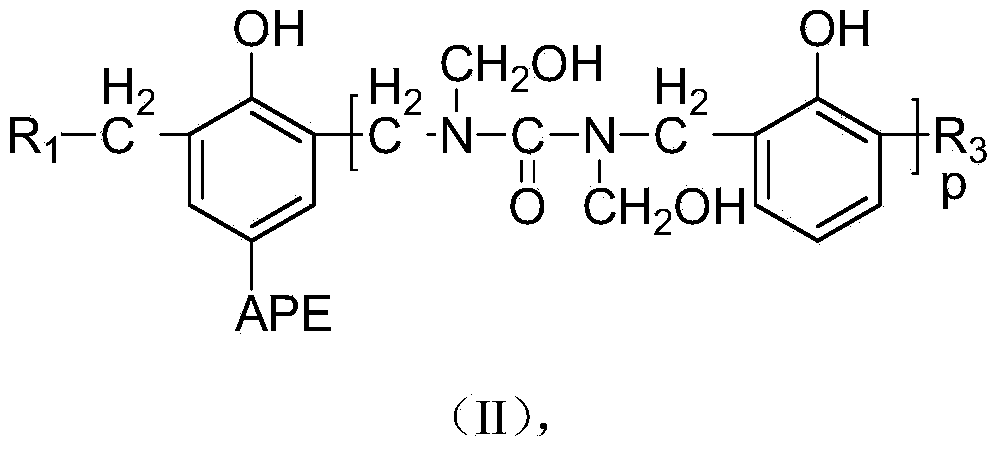

[0034] (1) Add formaldehyde to the reactor and start stirring, add urea and o-cresol at room temperature, adjust the pH to 1-2 with sulfuric acid; the molar ratio of urea, formaldehyde and o-cresol is 1:4: 2;

[0035] (2) Raise the temperature to 90°C, hold the reaction for 4 hours, then raise the temperature to 100°C, and hold the reaction for 2 hours;

[0036] (3) Add APE in an equimolar amount to formaldehyde at 100°C, and carry out alkylation reaction at 100°C for 2 hours to obtain the product;

[0037] After the reaction is completed, the temperature is lowered to below 40°C and the material is discharged.

[0038] In the APE described in step (3) of this embodiment: m is 20, n is 10, R 2 For methyl.

Embodiment 2

[0040] A preparation method of demulsifier, the steps are as follows:

[0041] (1) Add formaldehyde to the reactor and start stirring, add urea and o-ethylphenol at room temperature, adjust the pH to 2-3 with sulfuric acid; the molar ratio of urea, formaldehyde and o-ethylphenol is 1:4: 3;

[0042] (2) Raise the temperature to 95°C, hold the reaction for 2 hours, then raise the temperature to 105°C, and hold the reaction for 1 hour;

[0043] (3) Add APE in an equimolar amount to formaldehyde at 105°C, and carry out alkylation reaction at 105°C for 1 hour to obtain the product;

[0044] After the reaction is completed, the temperature is lowered to below 40°C and the material is discharged.

[0045] In the APE described in step (3) of this embodiment: m is 80, n is 40, R 2 For ethyl.

Embodiment 3

[0047] A preparation method of demulsifier, the steps are as follows:

[0048] (1) Add formaldehyde to the reactor and start stirring, add urea and o-isopropylphenol at room temperature, and adjust the pH to 3-4 with sulfuric acid; the molar ratio of urea, formaldehyde and o-isopropylphenol is 1: 4:2.5;

[0049] (2) Raise the temperature to 95°C, hold the reaction for 2 hours, then raise the temperature to 105°C, and hold the reaction for 1 hour;

[0050] (3) Add APE in an equimolar amount to formaldehyde at 105°C, and carry out alkylation reaction at 105°C for 1 hour to obtain the product;

[0051] After the reaction is completed, the temperature is lowered to below 40°C and the material is discharged.

[0052] In the APE described in step (3) of this embodiment: m is 25, n is 15, R 2 For isopropyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com