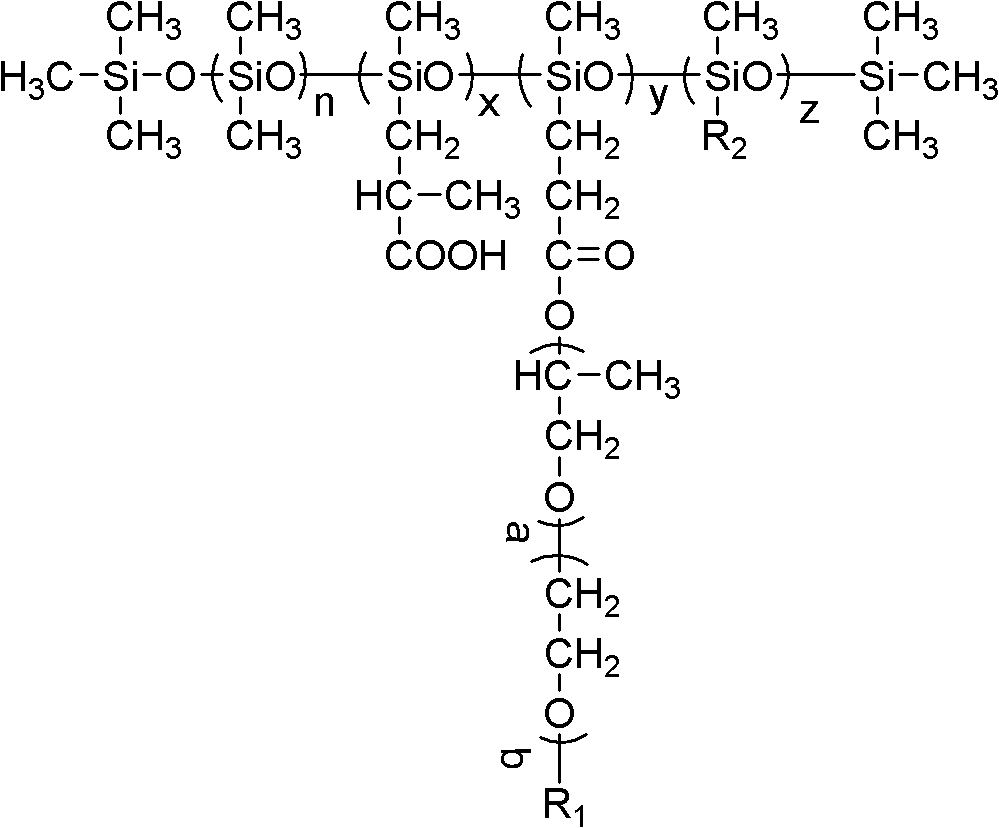

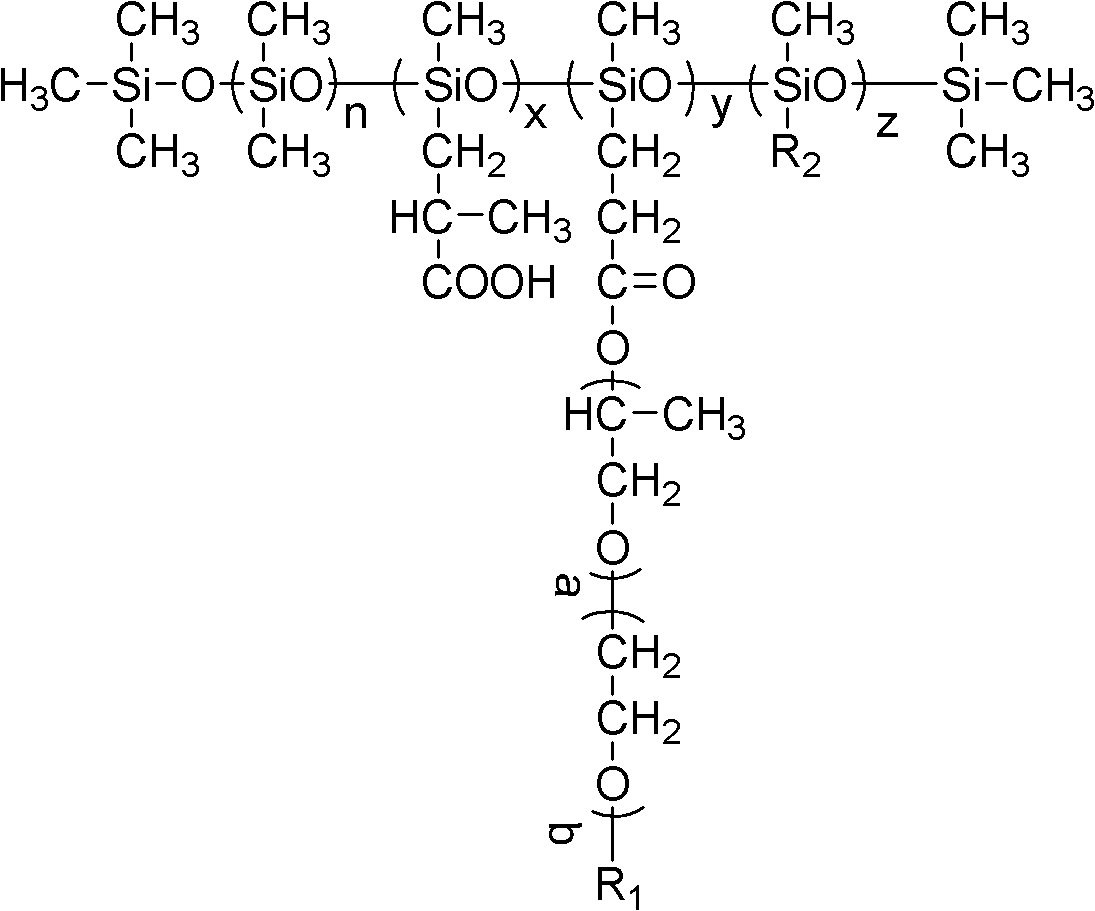

Comb-shaped polysiloxane crude-oil demulsifying agent and preparation method thereof

A crude oil demulsifier, polysiloxane technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of different, demulsification ability can not meet the current needs, the crude oil composition is very different, etc., to achieve water separation Fast, reduce the oil-water interfacial tension and interfacial strength, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

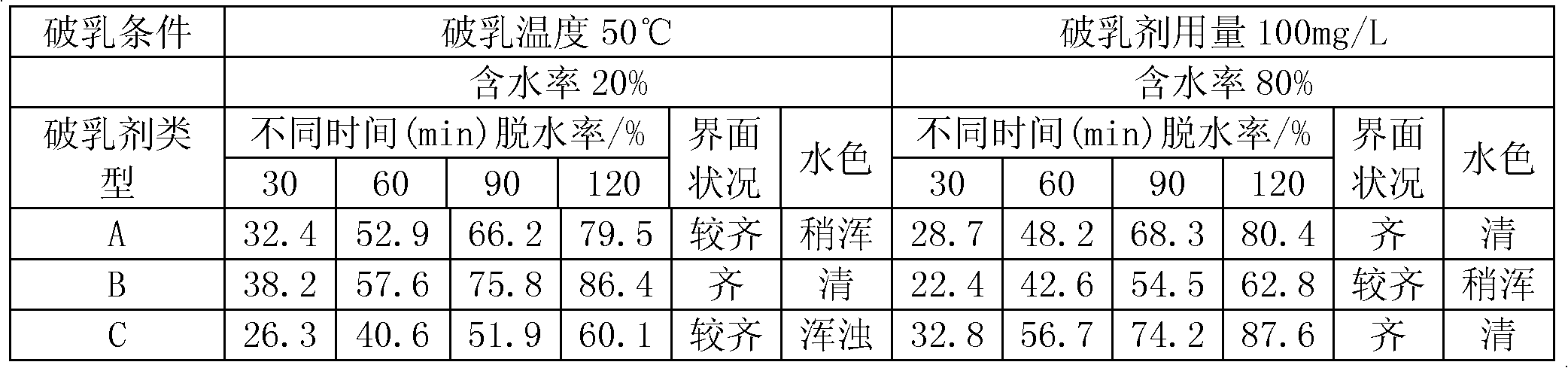

Examples

Embodiment 1

[0036] The preparation method of comb polysiloxane crude oil demulsifier comprises the following steps:

[0037] 1) Preparation of propylene glycol polyoxyethylene polyoxypropylene acrylate

[0038] Weigh 20.00g of propylene glycol polyoxyethylene polyoxypropylene ether (molecular weight 2000), 1.73g of acrylic acid, 0.43g of catalyst p-toluenesulfonic acid, 0.13g of polymerization inhibitor hydroquinone, and add In a three-necked flask with a condenser tube and a thermometer, heat to 140°C and reflux for 6 hours;

[0039] After the reaction was completed, the reactant was poured into a pear-shaped separatory funnel, 50ml of dichloromethane was added to make it completely dissolved, and then the pH was adjusted to neutrality with 0.05mol / L NaOH solution, after shaking well, the mixture was allowed to stand for stratification, and the mixture was separated. The lower layer liquid is removed, and the dichloromethane is evaporated with a rotary evaporator to obtain the product p...

Embodiment 2

[0046] The preparation method of comb polysiloxane crude oil demulsifier comprises the following steps:

[0047] 1) the preparation of propylene glycol polyoxyethylene polyoxypropylene acrylate is the same as Example 1

[0048] 2) Hydrosilation reaction

[0049] Weigh 20 g of hydrogen-containing silicone oil (hydrogen content 0.185%), 14.12 g of isopropanol, and 60 ppm of chloroplatinic acid into a four-necked flask equipped with a dropping funnel, a spherical condenser, a thermometer, and a stirrer, and heat to 110° C.;

[0050]The prepared propylene glycol polyoxyethylene polyoxypropylene acrylate 12.98g, methacrylic acid 0.53g, and methyl methacrylate 1.85g were mixed, then added to the hydrogen-containing silicone oil system at 110°C and slowly added dropwise for two hours to react. After the dropwise addition, the reaction was continued at 110°C for 4 hours;

[0051] 3) Separation of comb polysiloxane crude oil demulsifier

[0052] After the hydrosilylation reaction wa...

Embodiment 3

[0054] The preparation method of comb polysiloxane crude oil demulsifier comprises the following steps:

[0055] 1) the preparation of propylene glycol polyoxyethylene polyoxypropylene acrylate is the same as Example 1

[0056] 2) Hydrosilation reaction

[0057] Weigh 20 g of hydrogen-containing silicone oil (hydrogen content 0.185%), 14.12 g of isopropanol, and 60 ppm of chloroplatinic acid into a four-necked flask equipped with a dropping funnel, a spherical condenser, a thermometer, and a stirrer, and heat to 110° C.;

[0058] The prepared propylene glycol polyoxyethylene polyoxypropylene acrylate 15.58g, methacrylic acid 1.70g, and methyl methacrylate 0.25g were mixed, then added to the hydrogen-containing silicone oil system at 110°C and slowly added dropwise for two hours to react. After the dropwise addition, the reaction was continued at 110°C for 4 hours;

[0059] 3) Separation of comb polysiloxane crude oil demulsifier

[0060] After the hydrosilylation reaction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com