A kind of low temperature crude oil demulsifier and preparation method thereof

A crude oil demulsifier and low-temperature technology, which is applied in the direction of dehydration/demulsification by chemical methods, can solve the problems of oil and gas gathering and transportation and crude oil refining, consume large energy, and take a long time to overcome the problems of long demulsification time and demulsification The effect of low milk temperature and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

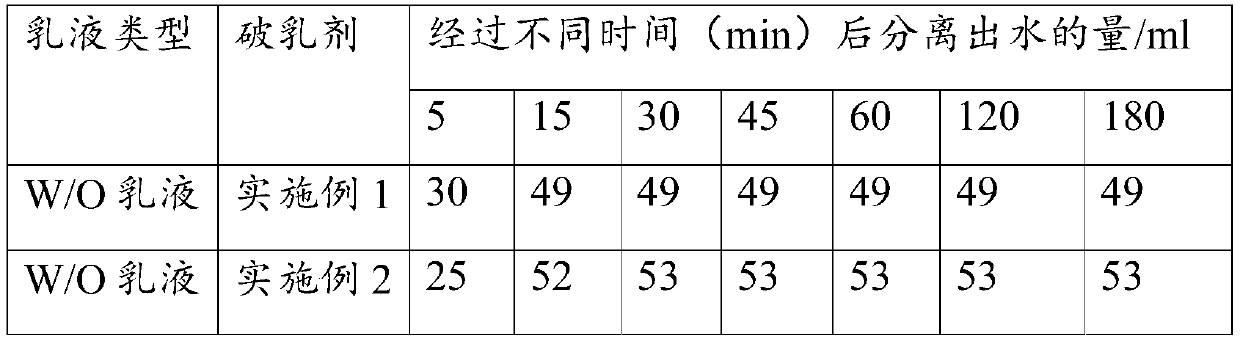

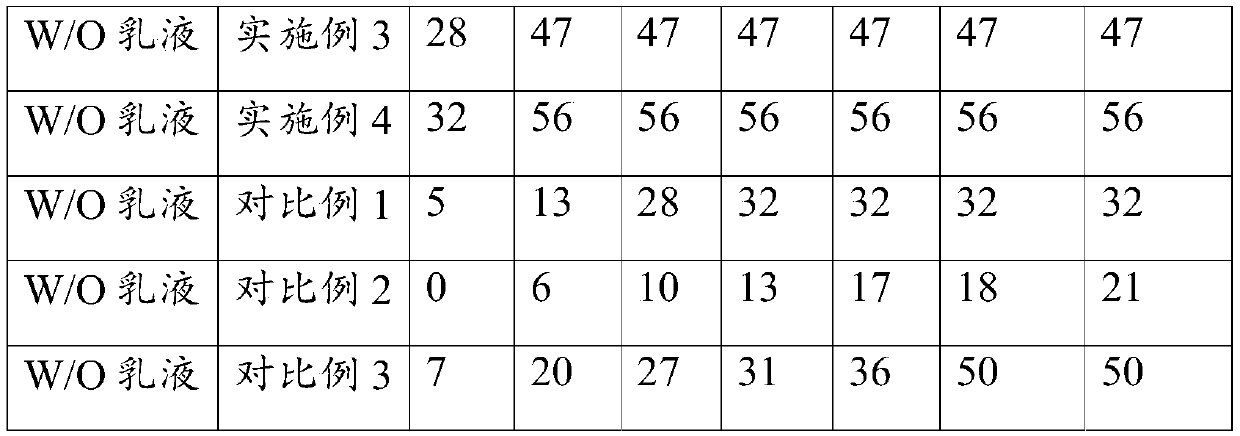

Examples

Embodiment 1

[0015] The low-temperature crude oil demulsifier of the present embodiment is made of the following raw materials in parts by weight: 56 parts of ethylenediamine, 28 parts of methanol, 37 parts of hexafluorobutyl methacrylate, 19 parts of petroleum sulfonate, 24 parts of sodium persulfate 21 parts of sodium lauryl sulfate, 14 parts of sodium dimethyldithiocarbamate and 10 parts of dodecyl mercaptan.

[0016] The preparation method of the low temperature crude oil demulsifier of the present embodiment: comprise the following steps:

[0017] S1. Raw materials were weighed according to weight ratio: 56 parts of ethylenediamine, 28 parts of methanol, 37 parts of hexafluorobutyl methacrylate, 19 parts of petroleum sulfonate, 24 parts of sodium persulfate, sodium lauryl sulfate 21 parts, 14 parts of sodium dimethyl dithiocarbamate and 10 parts of dodecyl mercaptan;

[0018] S2. Add sodium lauryl sulfate into a four-necked flask, add 3 times the weight of deionized water, feed nitro...

Embodiment 2

[0022] The low-temperature crude oil demulsifier of the present embodiment is made from the following raw materials in parts by weight: 44 parts of ethylenediamine, 28 parts of methanol, 34 parts of hexafluorobutyl methacrylate, 16 parts of petroleum sulfonate, and 17 parts of sodium persulfate. 25 parts of sodium lauryl sulfate, 16 parts of sodium dimethyldithiocarbamate and 8 parts of dodecyl mercaptan.

[0023] The preparation method of the low temperature crude oil demulsifier of the present embodiment: comprise the following steps:

[0024] S1. Raw materials were weighed according to weight ratio: 44 parts of ethylenediamine, 28 parts of methanol, 34 parts of hexafluorobutyl methacrylate, 16 parts of petroleum sulfonate, 17 parts of sodium persulfate, sodium lauryl sulfate 25 parts, 16 parts of sodium dimethyl dithiocarbamate and 8 parts of dodecyl mercaptan;

[0025] S2. Add sodium lauryl sulfate into a four-necked flask, add 2 times the weight of deionized water, feed ...

Embodiment 3

[0029] The low-temperature crude oil demulsifier of the present embodiment is made from the following raw materials in parts by weight: 55 parts of ethylenediamine, 21 parts of methanol, 32 parts of hexafluorobutyl methacrylate, 17 parts of petroleum sulfonate, and 20 parts of sodium persulfate. Parts, 22 parts of sodium lauryl sulfate, 16 parts of sodium dimethyldithiocarbamate and 12 parts of dodecyl mercaptan.

[0030] The preparation method of the low temperature crude oil demulsifier of the present embodiment comprises the following steps:

[0031] S1. Raw materials were weighed according to weight ratio: 55 parts of ethylenediamine, 21 parts of methanol, 32 parts of hexafluorobutyl methacrylate, 17 parts of petroleum sulfonate, 20 parts of sodium persulfate, sodium lauryl sulfate 22 parts, 16 parts of sodium dimethyl dithiocarbamate and 12 parts of dodecyl mercaptan;

[0032] S2. Add sodium lauryl sulfate into a four-neck flask, add 3 times the weight of deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com