Extra-heavy oil functional demulsifier as well as preparation and application thereof

A technology of extra-heavy oil and demulsifier, which is applied in the field of extra-heavy oil functional demulsifier and its preparation and application. It can solve the problems of inability to obtain a stable electric field and high investment in equipment, and achieve improved demulsification effect, low demulsification temperature, Effects that change surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

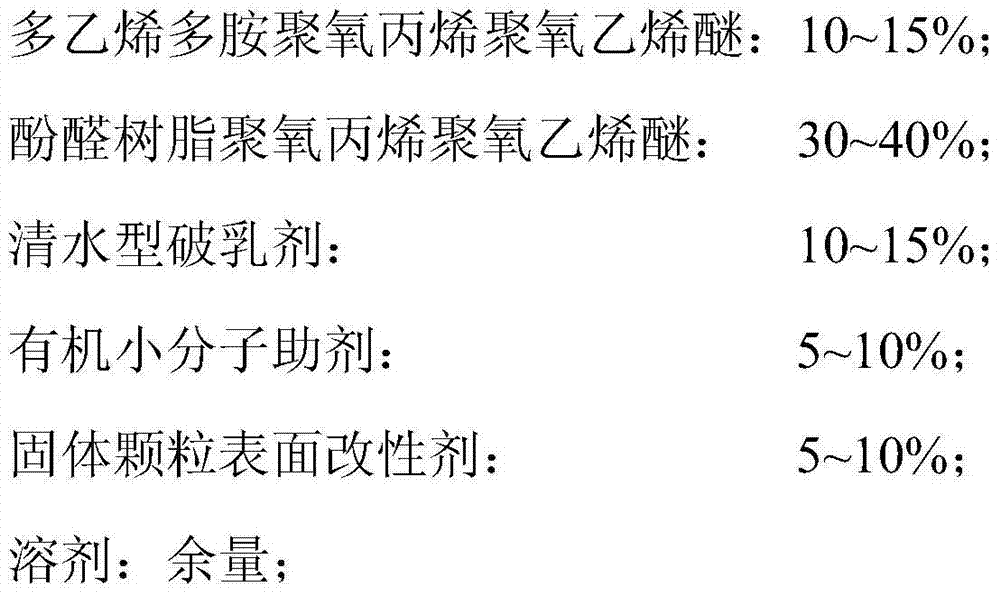

[0038] The components and mass fraction of the functional demulsifier are:

[0039] A. Polyethylene polyamine polyoxypropylene polyoxyethylene ether (industrial product): 10%;

[0040] B, phenolic resin polyoxypropylene polyoxyethylene ether (industrial product): 40%;

[0041] C. Clear water type demulsifier (industrial product): 10%;

[0042] D, diethylene glycol butyl ether (industrial product): 5%;

[0043] E. Solid particle surface modifier: 5%;

[0044] F: Benzene (industrial product): 30%.

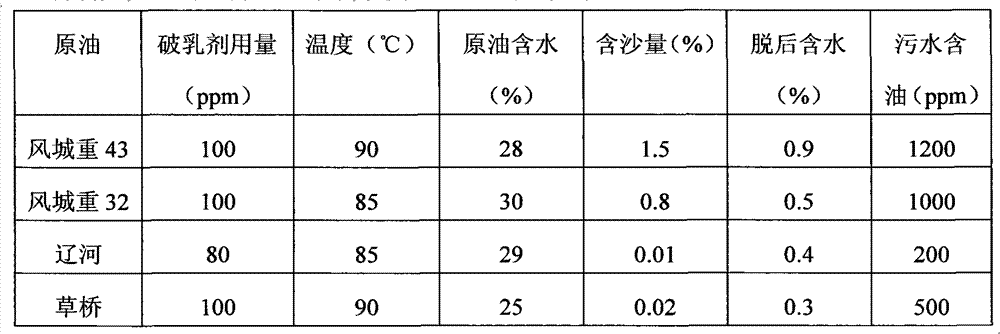

[0045] The demulsification effect of this functional demulsifier on different heavy oils is shown in the table below:

[0046]

Embodiment 2

[0048] The components and mass fraction of the functional demulsifier are:

[0049] A. Polyethylene polyamine polyoxypropylene polyoxyethylene ether (industrial product): 10%;

[0050] B, phenolic resin polyoxypropylene polyoxyethylene ether (industrial product): 35%;

[0051] C. Water-type demulsifier (industrial product): 5%;

[0052] D, ethanol (industrial product): 5%;

[0053] E, solid particle surface modifier (self-made): 10%;

[0054] F: methanol (industrial product): 35%.

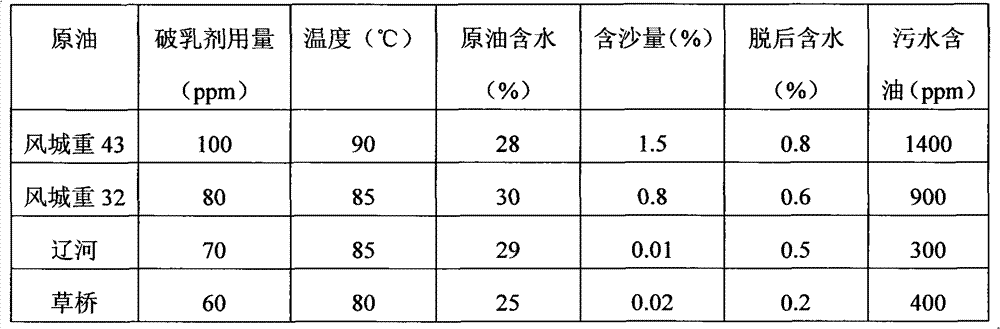

[0055] The demulsification effect of this functional demulsifier on different heavy oils is shown in the table below:

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com