Output yarn traction method of yarns for carpet production and special creel

A yarn and carpet technology is applied in the field of yarn output and traction method for carpet production and its special creel. Output, improve the quality of carpet products, reduce the effect of the area occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

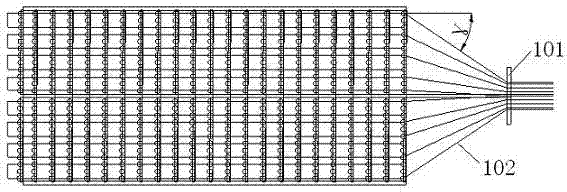

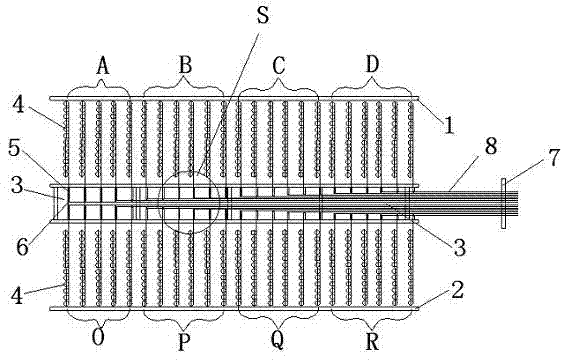

[0022] Embodiment 1: with reference to attached figure 2 , 3 . A yarn output drawing method for carpet production yarn, comprising the following steps:

[0023] ①Firstly, the creel is made into the structure of the upper frame body 1 and the lower frame body 2, and a yarn output area is left in the middle of the upper frame body 1 and the lower frame body 2, and a plurality of pulling yarns 8 are fixed in the yarn output area. Yarn guide rod 6;

[0024] ②The bobbin positioning rods 4 in the upper frame body 1 and the lower frame body 2 are vertically arranged in several rows, and the upper frame body 1 is divided into areas A, B, C, and D for placing yarns 8 of four different colors. , each color area includes more than two rows of bobbin positioning rods 4, and in the same way, other four different color yarns 8 are placed in the areas O, P, Q, and R divided in the lower frame body 2;

[0025] ③ Pull out the yarn 8 on the positioning rod 4 of each row of yarn tubes, bypa...

Embodiment 2

[0027] Embodiment 2: on the basis of embodiment 1, with reference to appended figure 2 , 3 . A kind of creel for carpet production dedicated to the method of pulling yarn out of yarn for carpet production described in Example 1, which includes an upper frame body 1, a lower frame body 2 and a middle yarn outlet 3; an upper layer frame body 1 and a The lower frame body 2 is provided with several vertical columns; each column is vertically equipped with a plurality of bobbin positioning rods 4, and the bobbin positioning rods 4 are arranged on the columns from top to bottom; On the bobbin positioning rod 4; in the upper frame body 1, every several adjacent columns are divided into a color area, and only one color of yarn is fixed in the color area; the upper frame body 1 is divided into A and B , C, and D four different color areas; the bobbin positioning rod 4 in the lower frame body 2 and the bobbin positioning rod 4 in the upper frame body 1 are symmetrically arranged, and...

Embodiment 3

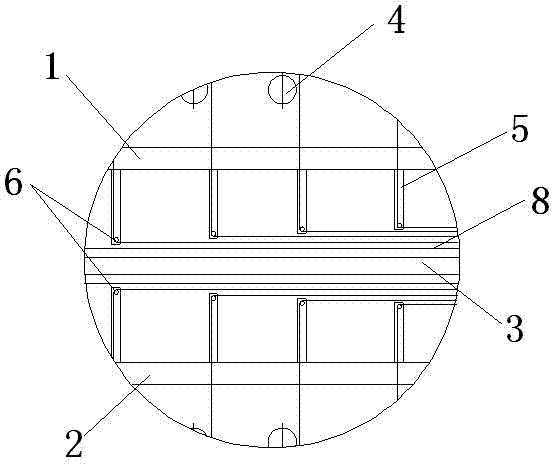

[0028] Embodiment 3: with reference to attached Figure 4 . A yarn output drawing method for carpet production yarn, comprising the following steps:

[0029] ①Firstly, the creel is made into the structure of the upper frame body 1 and the lower frame body 2, and a yarn output area is left in the middle of the upper frame body 1 and the lower frame body 2, and a plurality of pulling yarns 8 are fixed in the yarn output area. Yarn guide rod 6;

[0030]② The yarn bobbin positioning rods 4 in the upper frame body 1 and the lower frame body 2 are arranged in multiple rows, and the arrangement direction of each row of yarn bobbin positioning rods 4 is inclined, forming an obtuse angle with the horizontal direction. Divided into areas A, B, C, and D for placing yarns 8 of four different colors, each color area includes more than two rows of bobbin positioning rods 4, and the other four yarns 8 of different colors are placed on the lower layer in the same way In the areas O, P, Q, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com