Indoor soft floor tile and manufacturing method thereof

A production method and technology for floor tiles, applied in chemical instruments and methods, lamination auxiliary operations, lamination and other directions, can solve the problems of complex construction, high cost, hard foot feeling, etc., and achieve high specification accuracy and good waterproof performance. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

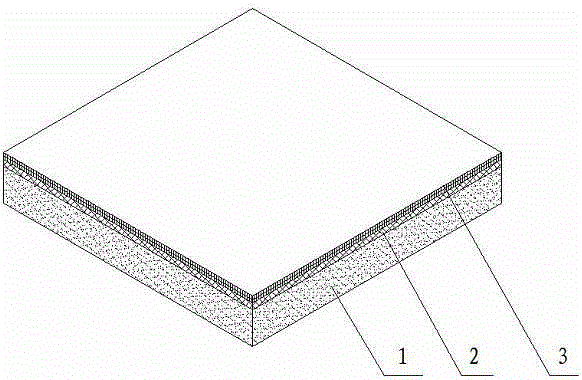

Image

Examples

Embodiment Construction

[0027] A method for making indoor soft floor tiles, characterized in that it includes the following steps in sequence:

[0028] (A) Selection of raw materials: The components and their mass percentages in the selected raw materials are: 90% of waste rubber particles, 2% of multi-color and multi-pattern PVC sheets of a certain thickness in the required design and color, 7% of polyurethane adhesive, UV Paint 1%;

[0029] (B) Making the fabric: Cut the multi-color and multi-pattern PVC sheet into squares with a certain side length with a cutting machine, that is, the fabric for indoor soft floor tiles;

[0030] (C) Making base material: firstly, mix waste rubber particles and polyurethane adhesive according to the mass ratio of 100: (8-12), add them to the mixer and stir for 10-15 minutes, then add them to the curing machine In the process, heat up to 140-160°C with electricity or oil, and solidify the mixture of waste rubber particles and polyurethane adhesive at this temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com