Excavation technique for shallow-buried large-span small-spacing loess tunnel

A technology for tunnel excavation and loess tunnels is applied in the field of excavation of loess tunnels with large spans and small clear distances. Application value and academic value, the effect of reducing the loss of surrounding rock bearing capacity and ensuring structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

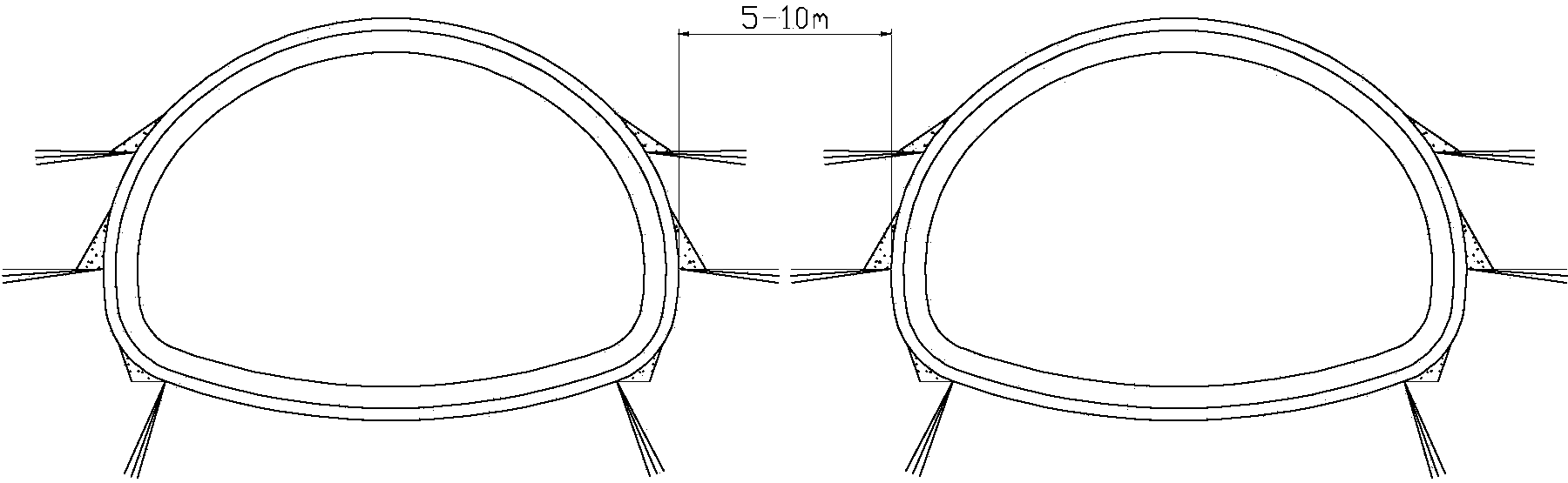

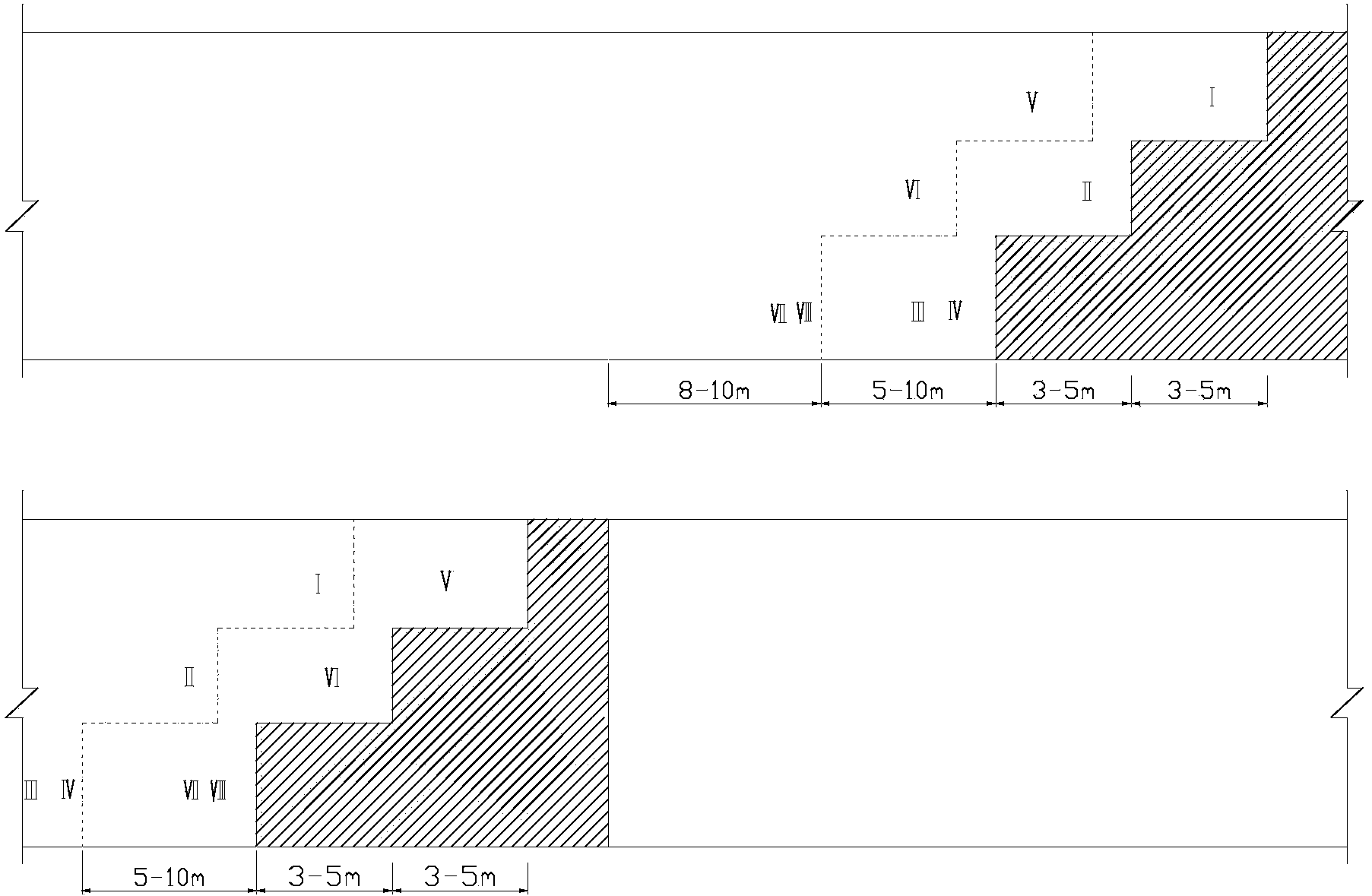

[0035] In the present invention, two tunnels are constructed at the same time, and both tunnels are excavated. The two tunnels of the two tunnels adopt the method of leaving core soil on three steps. side.

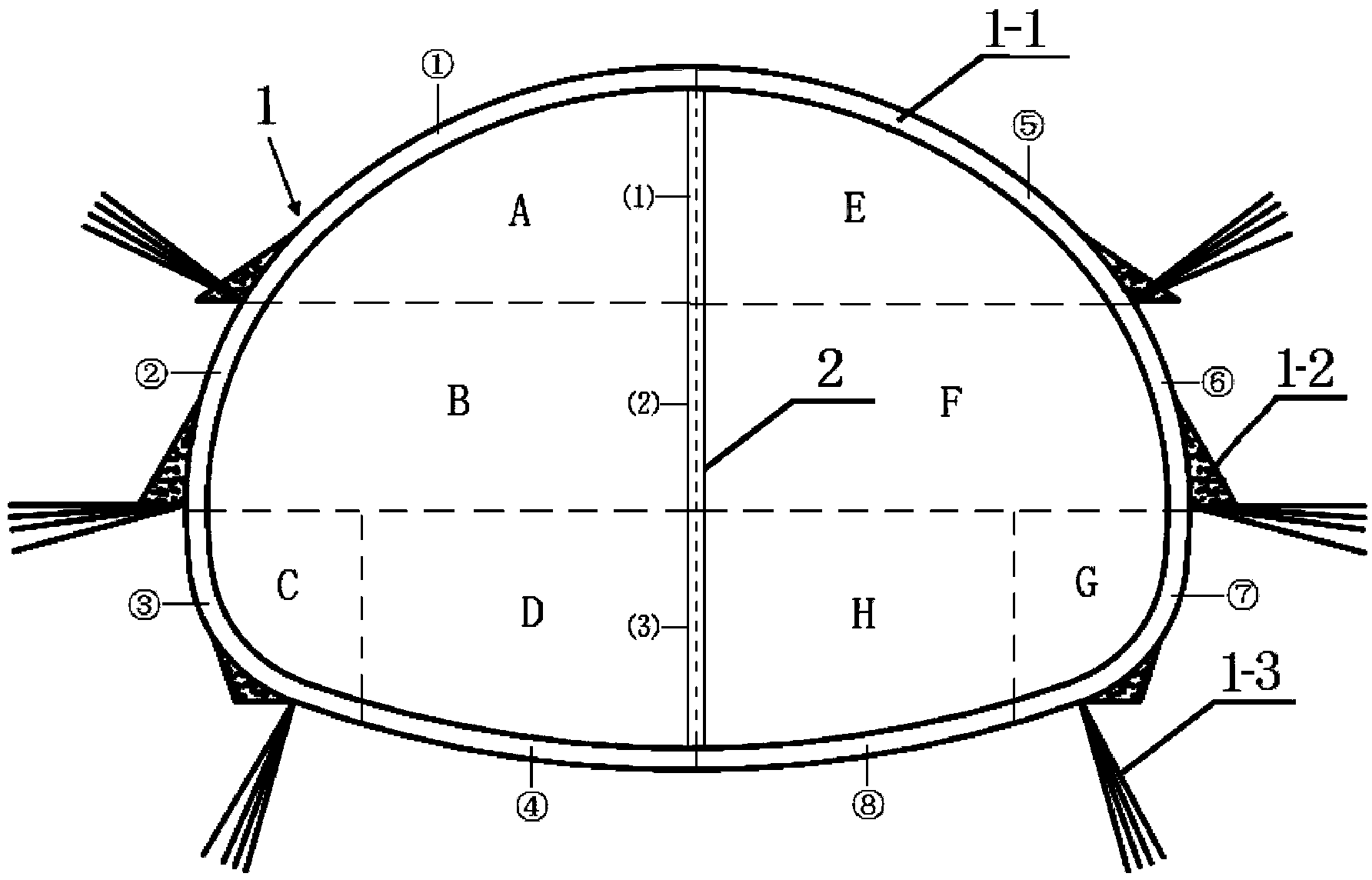

[0036] The excavation method of a loess tunnel with a large span and a small clear distance of the present invention is divided into left and right tunnel construction. After the construction, the structures of the left and right holes are the same. figure 1 Shown in is its structure. During construction, the left hole can be excavated first, and the right hole can also be excavated first. Each side guide hole of the left and right holes is excavated in three steps of upper step, middle step and lower step.

[0037] refer to figure 1 Shown, a kind of large-span small distance loess tunnel excavation method of the present invention, its excavation steps are:

[0038] 1. Excavate the left hole

[0039] Step 1 Excavate the left upper part of the left hole (Part A),

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com