Method for measuring swing arm ball head stress

A swing arm ball head and ball pin technology, which is applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of high price, data accuracy discount, long test cycle, etc., and achieve low cost, high versatility, and measurement The result is precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The specific embodiment of the present invention comprises the following steps:

[0017] A. Preparation: first use coarse sandpaper to remove the surface coating at the position to be patched, and polish it smooth; measure the diameter of the largest circle of the ball head cone, calculate the 1 / 4 arc length, and use a vernier caliper to divide the largest circle of the cone into For 4 1 / 4 arcs, use a scribe to deepen the traces of the dividing points; use fine sandpaper to polish the four patch positions determined after scribing along the axis at a 45-degree angle until the surface is smooth; use tweezers to hold a small amount of cotton and dip it in alcohol , scrub the patch position in one direction, and replace the cotton until there is no stain on the cotton.

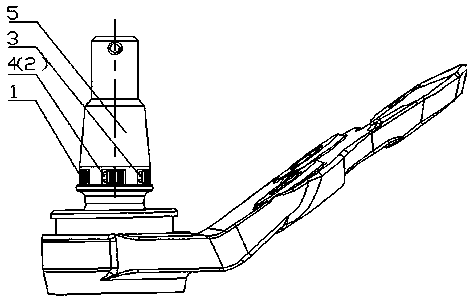

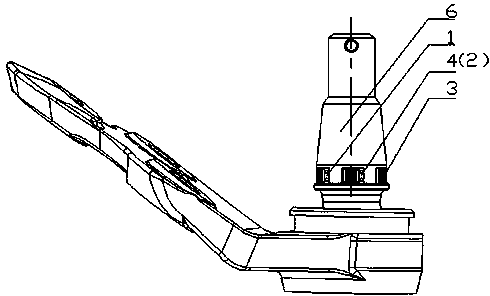

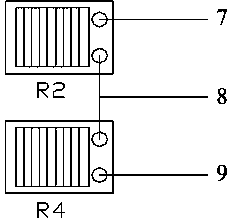

[0018] B. Strain gauge pasting: such as Figure 1-Figure 2 As shown, paste the strain gauges R1, R2, R3, and R4 on the left swing arm ball head 5 and the right swing arm ball head 6 with the same pasting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com