Ultraviolet LED exposure machine optical exposure illumination system and ultraviolet LED exposure machine

A technology of optical exposure and lighting system, which is applied in the field of exposure lighting of exposure machines, and can solve problems such as underexposure and overexposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is further described:

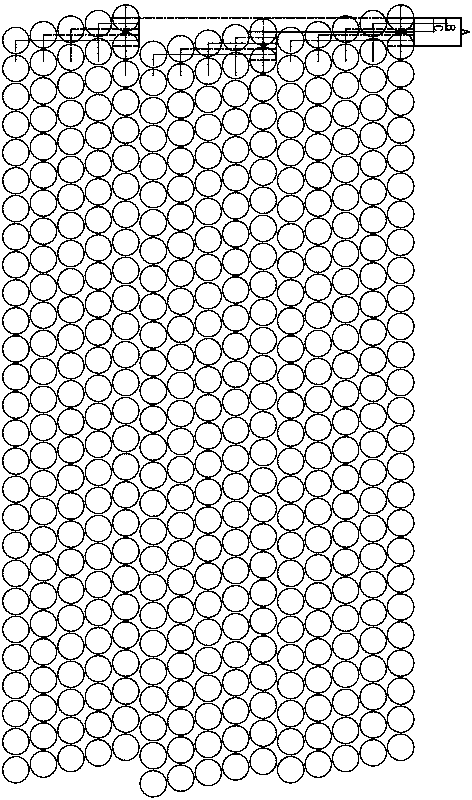

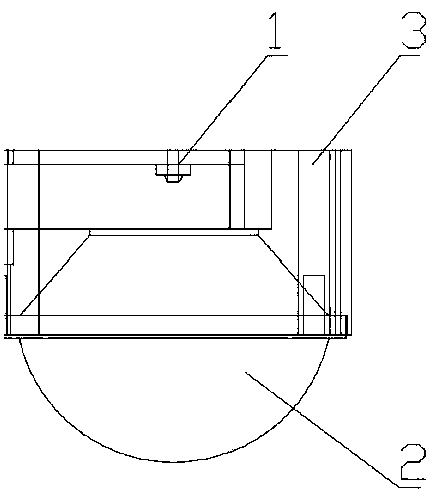

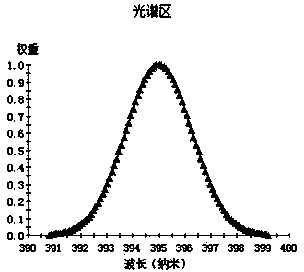

[0026] see figure 1 and figure 2 , an optical exposure lighting system for an ultraviolet LED exposure machine, comprising at least one light source mounting plate, a collimating lens 2, and an exposure lighting matrix arranger 3 for fixing the distance between the collimating lens 2 and the light source on the light source mounting plate, the light source Multiple rows of equidistantly arranged ultraviolet LED light sources 1 are sequentially arranged on the mounting board, the distance between the centers of two adjacent ultraviolet LED light sources 1 in each row is A, and the centers of ultraviolet LED light sources 1 in the same column in two adjacent rows The distance is B, B=A / number of rows, and two adjacent ultraviolet LED light sources 1 are arranged equidistantly. When designing 5 rows, the distance between the center of the first UV LED light source 1 in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com