Vertical-external-cavity surface-emitting semiconductor laser with integrated micro lens

A microlens and laser technology, applied in semiconductor lasers, lasers, laser parts, etc., can solve the problems of unstable working state of external cavity structure external cavity mirror, unsatisfactory laser spectral linewidth, and poor mode stability, etc. Large-scale low-cost production, reduced divergence angle, and less impact on the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure of the present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

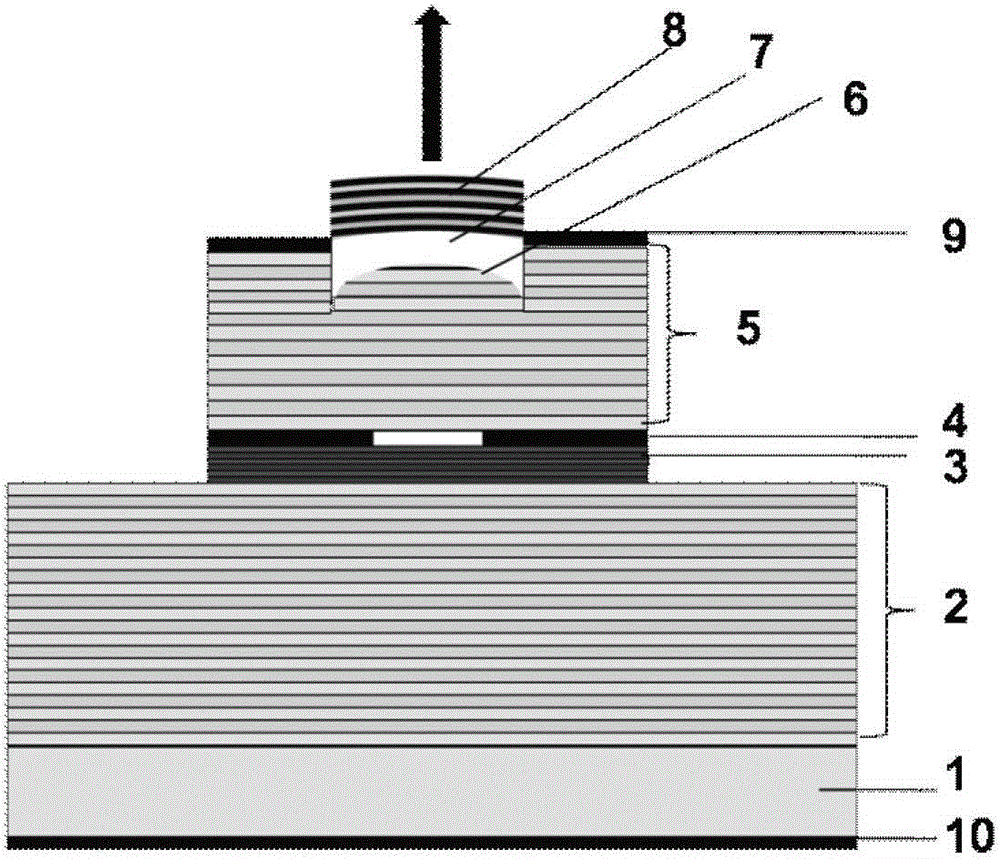

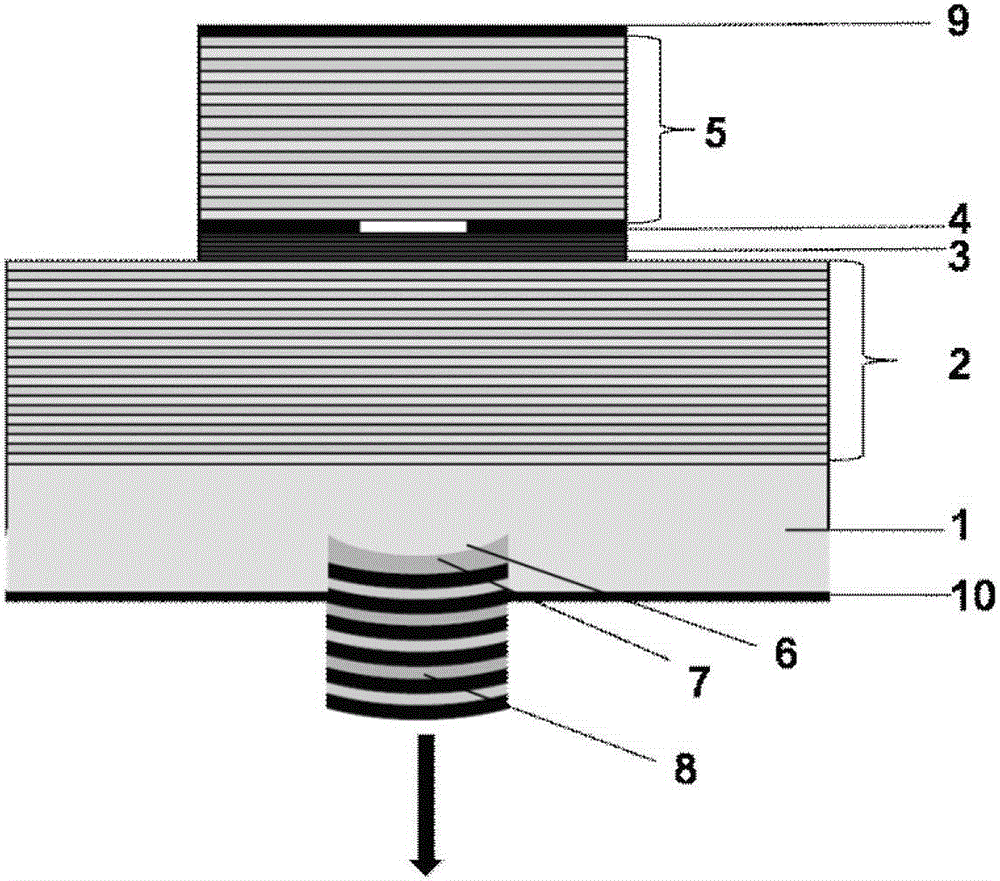

[0014] Such as figure 1 It is shown that the light output from the P surface of the present invention has a microlens integrated VECSEL structure, and the device structure emits laser light from the side of the P-type DBR. The structure from bottom to top is N-face electrode 10, N-type substrate 1, N-type DBR 2, active layer 3, oxidation limiting layer 4, P-type DBR 5, microlens structure 6, external coupling cavity 7, and external cavity DBR Mirror 8, and P surface electrode 9. Both the N-face electrode and the P-face electrode are electrically connected to the device. The microlens structure 6 is a lens shape with a certain curvature directly etched on the P-type DBR. The external coupling cavity 7 and the external cavity DBR mirror 8 are formed after epitaxial growth on the microlens structure 6 .

[0015] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com