Near single module quasi gradient refractive rate large mode field gain optical fiber and preparation method

A technology of graded-refractive-index and gain fiber, applied in the field of optics, can solve problems such as difficult single-mode output and limited mode field area, and achieve the effect of improving absorption utilization rate, good utilization rate, and high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the near-single-mode quasi-graded-index large-mode-field-gain optical fiber provided by the present invention is: the method comprises the following steps:

[0046] 1) Preparation of rare earth doped fiber core rod:

[0047] 1.1) Using chemical vapor deposition MCVD and solution doping or rare earth chelate vapor deposition, the rare earth compound is evenly mixed into the deposition layer in the quartz tube to form a large mode field quartz optical fiber core layer;

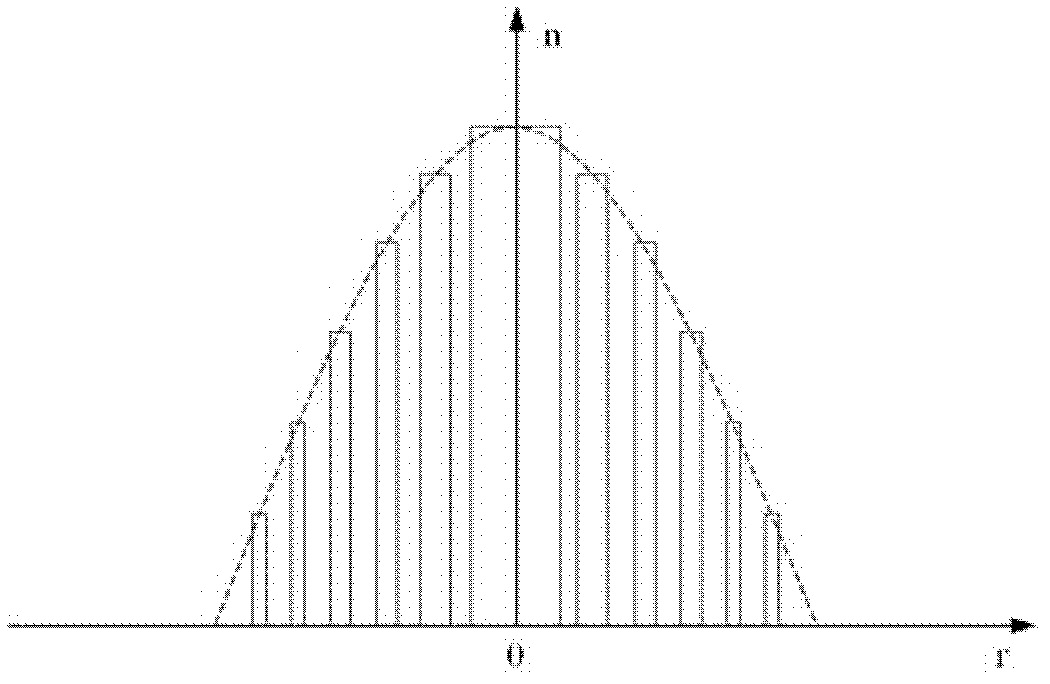

[0048]1.2) The large-mode-field silica fiber core layer obtained in step 1.1) is drawn into several small core rods with uniform diameters by a pre-stretching process, and the small core rods are integrated to form a small core rod group to form a rare earth-doped optical fiber Mandrel;

[0049] 2) Make a non-uniform Bragg cladding casing:

[0050] 2.1) Using chemical vapor deposition MCVD, changing the chemical composition of adjacent deposition layers to form alternating clad...

example 1

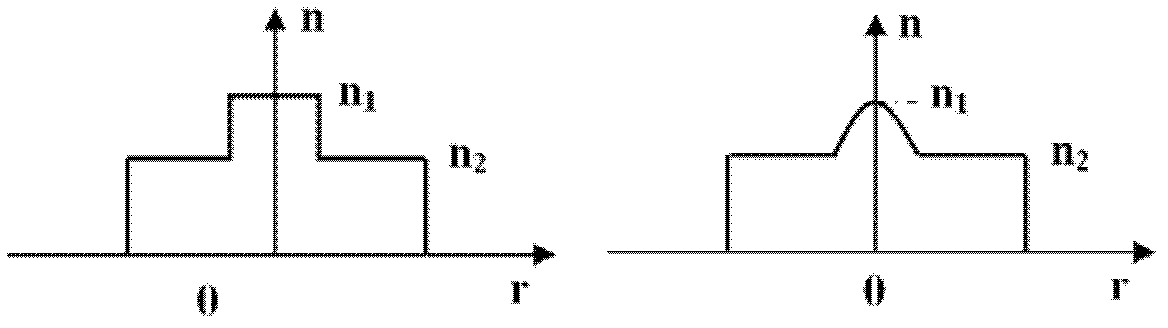

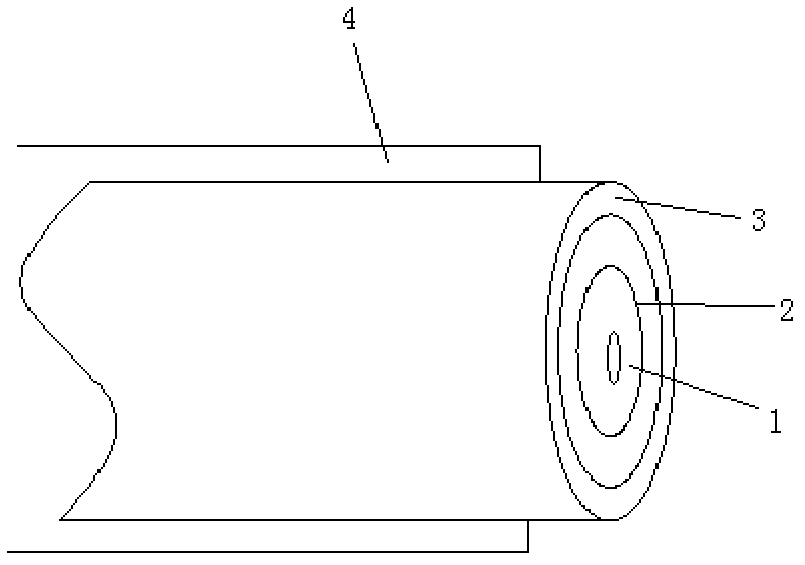

[0068] Example 1: A high-power cladding-pumped near-single-mode quasi-graded-index ytterbium-doped fiber, including a ytterbium-doped silica core 1, a ring gain region 2, a quartz cladding 3 and a low-refractive index coating 4, its structure The feature is that there is a fiber core satisfying the single-mode transmission condition in the cladding layer 3 . A series of loop gain regions 2 are concentrically distributed with the fiber.

example 2

[0069] Example 2: A high-power cladding-pumped near-single-mode quasi-graded-index three-core ytterbium-doped fiber, including three ytterbium-doped silica cores 1, annular gain region 2, silica cladding 3 and low-refractive index coating 4 , the structural feature is: three ytterbium-doped fiber cores with the same structure in the cladding 3 are parallel to each other and arranged symmetrically along the fiber cores, and the distance between the three ytterbium-doped fiber cores 1 is 1-20um. A series of loop gain regions 2 are concentrically distributed with the fiber.

[0070] Both the core 1 and the ring gain region 2 need to meet the single-mode transmission condition of the laser wavelength, according to the mode equation in the fiber:

[0071] Helmholtz equation:

[0072] d 2 Φ dr 2 + 1 r ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com