Aluminium alloy hot rolled strip transverse thickness distribution modeling method based on spectral method

A technology of thickness distribution and modeling method, which is applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

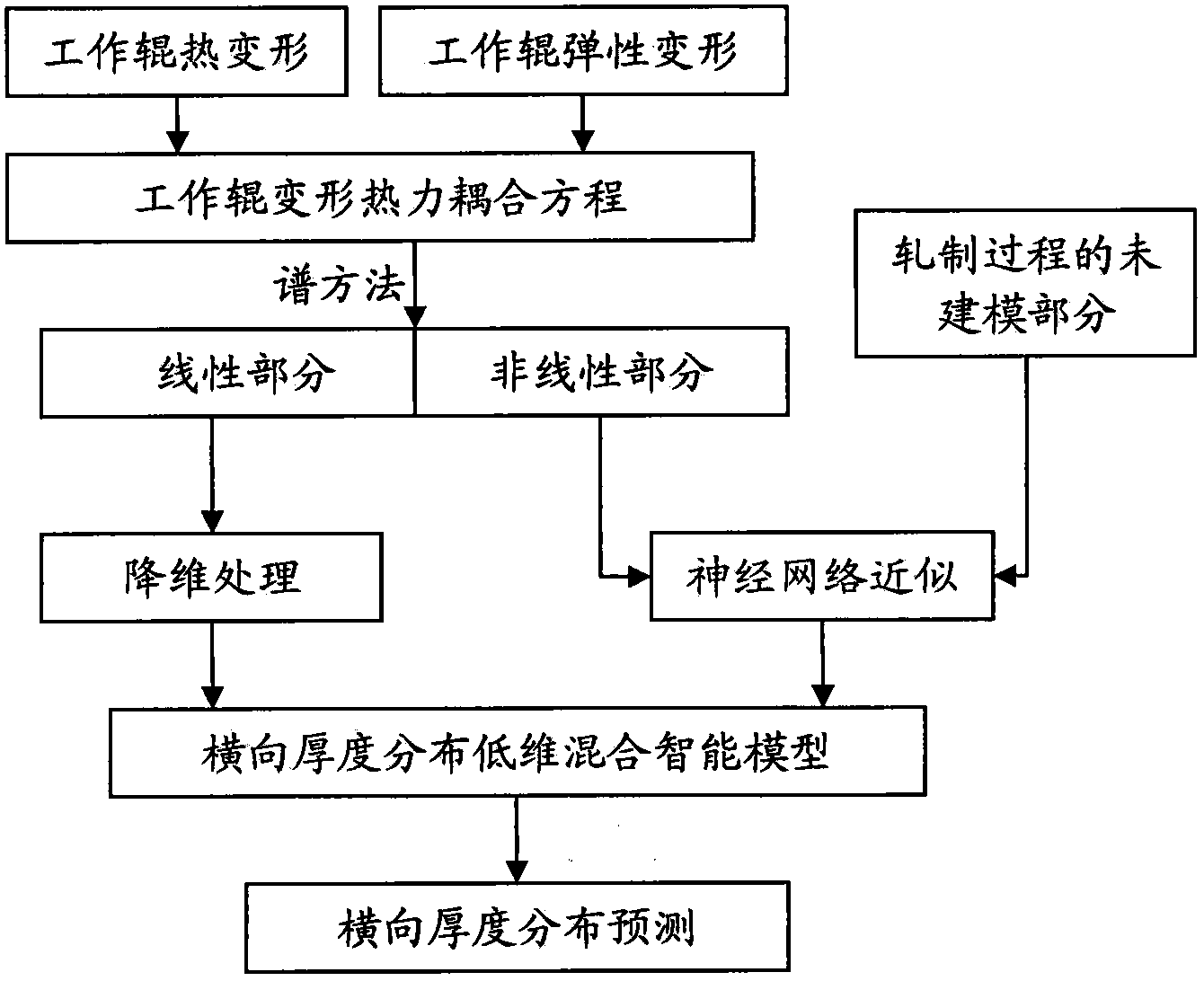

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The specific steps of establishing a prediction model for the transverse thickness distribution of the strip in the rolling process are as follows:

[0019] Step 1: Establishment of thermal-mechanical coupling equation for work roll deformation

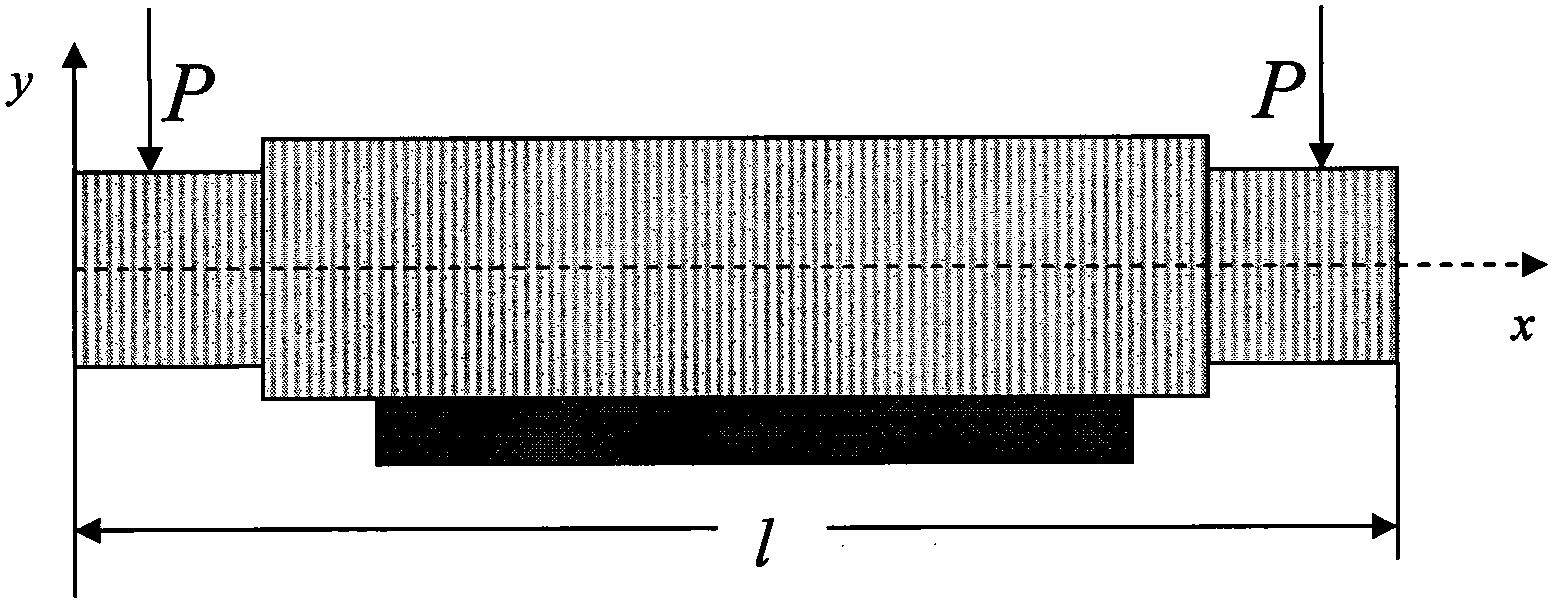

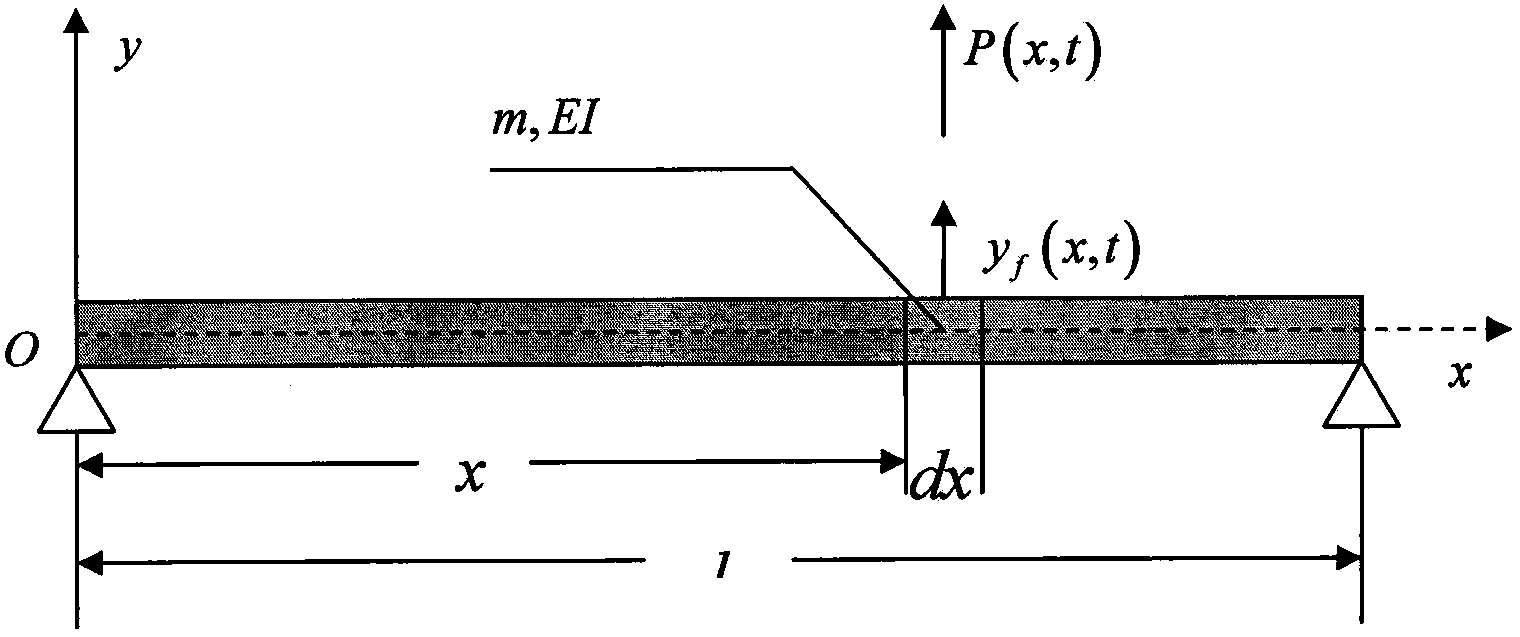

[0020] For elastic deformation, the work roll ( figure 2 ) is abstracted as a simply supported beam with length l ( image 3 ), the bending stiffness of the beam is EI, and the mass per unit length is m. The two ends of the roll are the fixed ends of the simply supported beam, and the middle of the roll is the free end. Certain assumptions are made on the deformation and force of the beam. According to the Bernoulli-Euler beam theory, the elasticity of the work roll can be obtained Deformation f The partial differential equation model of (x, t) is as follows:

[0021] m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com