A high-power crimping type igbt device

A crimping, high-power technology, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid state device components, etc., can solve the problems that affect the overall performance of the device, cannot be used universally, and cannot optimize the current path, so as to improve the uniformity of the current. The effect of distribution, suppression of high frequency oscillation, reduction of types and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

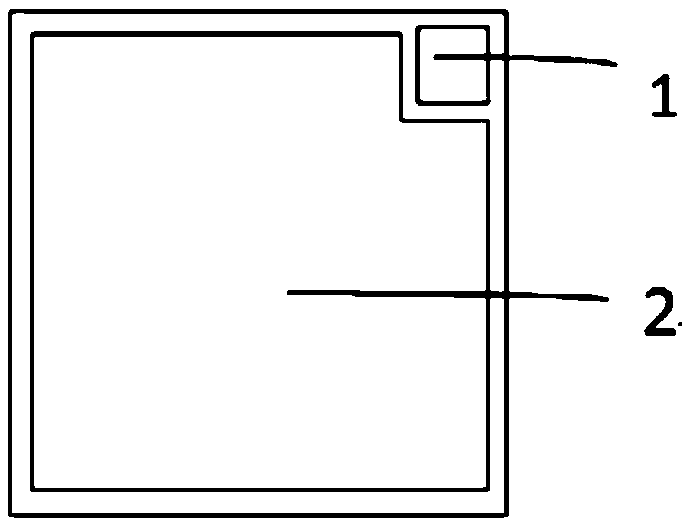

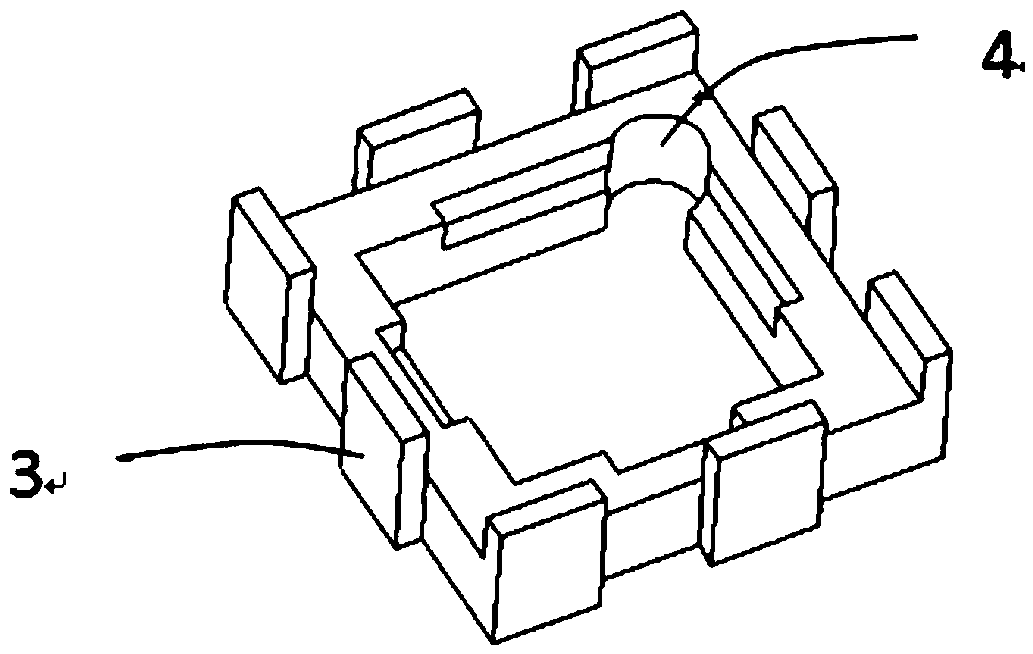

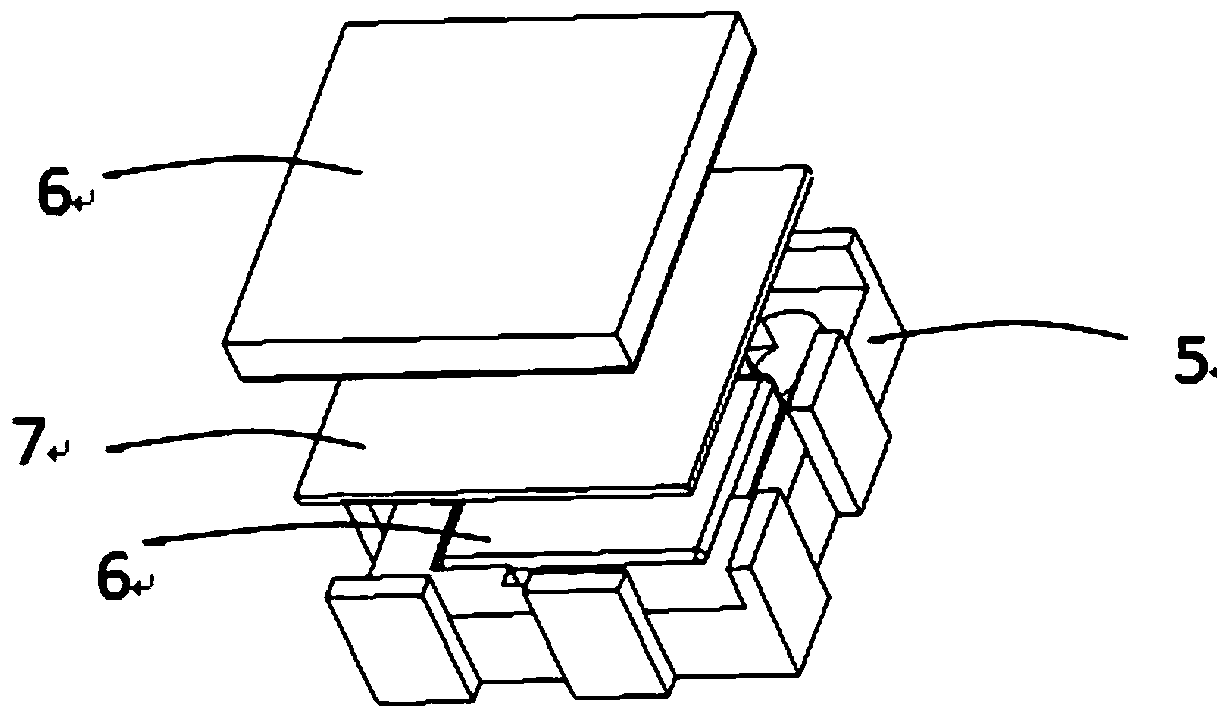

[0038] The invention provides a high-power crimping type IGBT device. The appearance of the crimping IGBT device is composed of two power electrodes and a ceramic shell on the side. The two power electrodes are respectively arranged at both ends of the shell. Inside the two power electrodes are a plurality of sub-modules containing power chips, and each sub-module contains a power chip. Depending on the current level of the entire device, there are several to dozens of power chips connected in parallel inside the crimping IGBT device, that is, several to dozens of sub-modules. The power chip inside the crimping IGBT device includes an IGBT chip and a freewheeling diode FWD chip connected in antiparallel to it. Typically, IGBT chips and FWD chips are rectangular thin silicon wafers with a thickness of several hundred mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com