A kind of processing technology of lead-acid raw plate battery

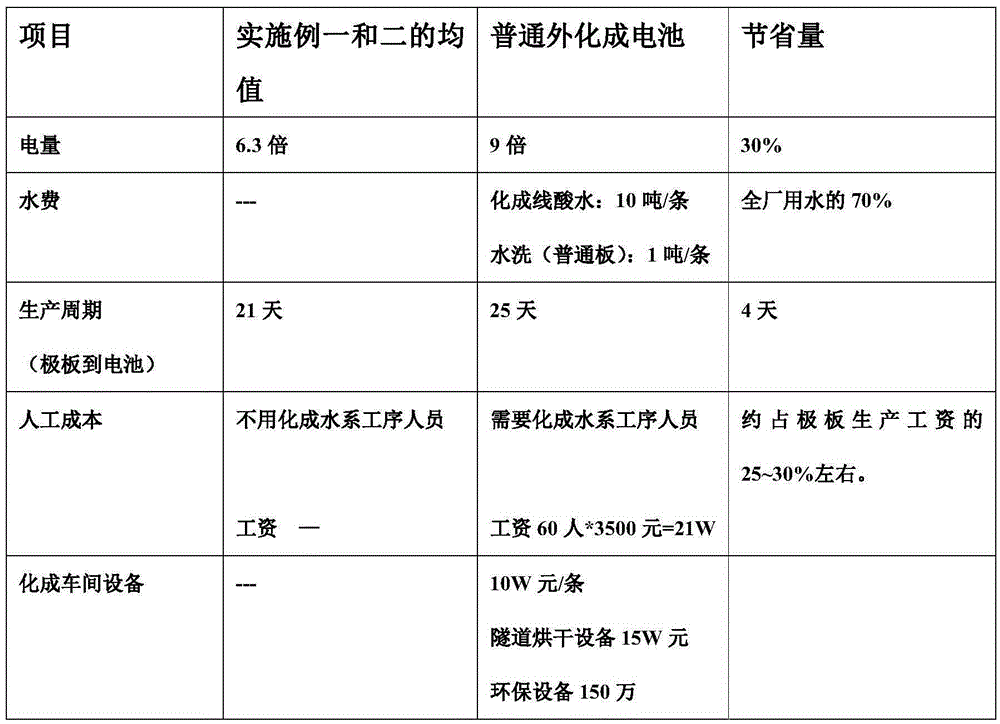

A processing technology and raw plate technology, applied in the direction of lead-acid battery electrodes, battery electrodes, electrode carriers/collectors, etc., can solve the problems of high cost consumption of hydropower processes, reduce labor costs, shorten production cycles, and save energy consumption The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of processing technology of lead-acid raw plate battery is as follows:

[0032] 1) prepare lead plaster, this lead paste comprises the following components by mass ratio: lead powder 95.8, dilute sulfuric acid 0.9, short fiber 0.5, tetrabasic lead sulfate 2.5, selenium 0.3; Stir it dry for 2 minutes, then add the weighed ingredients except dilute sulfuric acid at one time, stir for 5 minutes, add water and stir for 12 minutes, and then stir for 9 minutes, after stirring, add it again while stirring Weigh the diluted sulfuric acid, add it for 12-15 minutes, and then stir it for 20 minutes to evenly obtain the lead paste.

[0033] 3.2) plastering, providing a grid for making the positive pole plate, the lead paste is applied to the grid; the capillary acid absorption height of the grid is at 1.28g / mLH 2 SO 4 , ≥90mm / 5min at 25±3℃; its maximum pore diameter≤18μm; porosity≥90%; resistance≤0.0005Ω·dm 2 .

[0034] 3) curing, curing the paste on the grid; the curing...

Embodiment 2

[0051] A kind of processing technology of lead-acid raw plate battery is as follows:

[0052] 1) prepare lead paste, this lead paste comprises the following components by mass ratio: lead powder 91.5, dilute sulfuric acid 2, short fiber 1, tetrabasic lead sulfate 5, selenium 0.5; Stir it dry for 2 minutes, then add the weighed ingredients except dilute sulfuric acid at one time, stir for 5 minutes, add water and stir for 12 minutes, and then stir for 9 minutes, after stirring, add it again while stirring Weigh the diluted sulfuric acid, add it for 12-15 minutes, and then stir it for 20 minutes to evenly obtain the lead paste.

[0053] 2) plastering, providing a grid for making the positive pole plate, the lead paste is applied to the grid; the capillary acid absorption height of the grid is at 1.28g / mLH 2 SO 4 , ≥90mm / 5min at 25±3℃; its maximum pore diameter≤18μm; porosity≥90%; resistance≤0.0005Ω·dm 2 .

[0054] 3) curing, curing the paste on the grid; the curing process i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com