Micro-strip-to-waveguide vertical transition structure achieved through multi-layer step type substrate integration waveguide

A substrate-integrated waveguide and integrated waveguide technology, applied in the field of millimeter wave communication, can solve the problems of limited planar circuits and incompatibility of microstrip structures, and achieve the effect of realizing broadband performance and benefiting planar integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following descriptions are only preferred embodiments of the present invention, and it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some design and structure improvements and preparation method modifications can also be made. And retouching should also be regarded as the protection scope of the present invention.

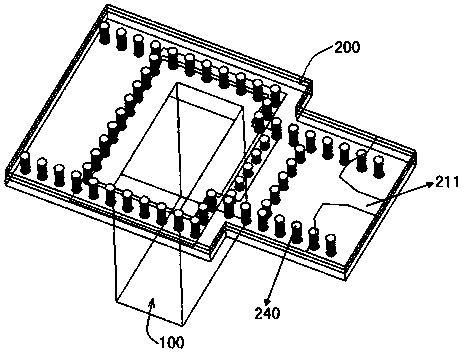

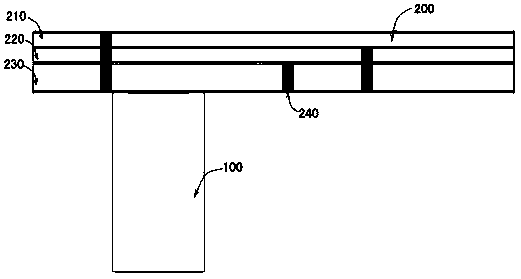

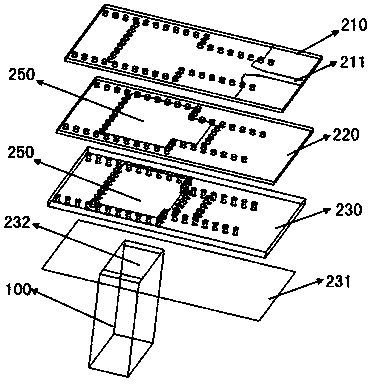

[0016] A multi-layer stepped substrate integrated waveguide realizes the vertical transition structure from microstrip to waveguide, which includes a stepped integrated waveguide structure and a rectangular waveguide. The stepped integrated waveguide structure includes a first substrate, a second substrate, and a third substrate stacked sequentially from top to bottom, and each layer of substrates is provided with an array of metallized through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com