External-cavity laser device with tunable wave length

A technology of lasers and wavelengths, applied in the field of lasers, can solve problems such as insufficient bandwidth, storage problems, and DFB lasers that cannot meet the wavelength range, and achieve high reliability, low cost, and reduced networking costs and network complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

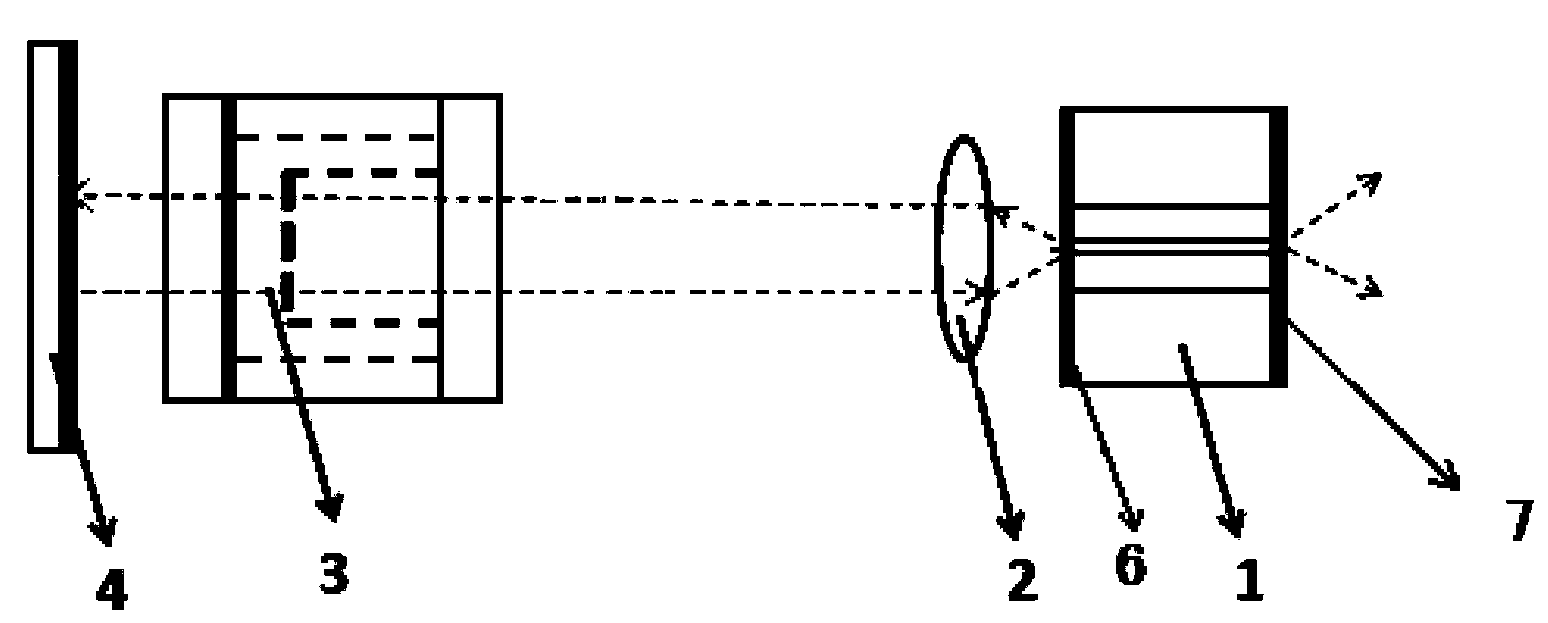

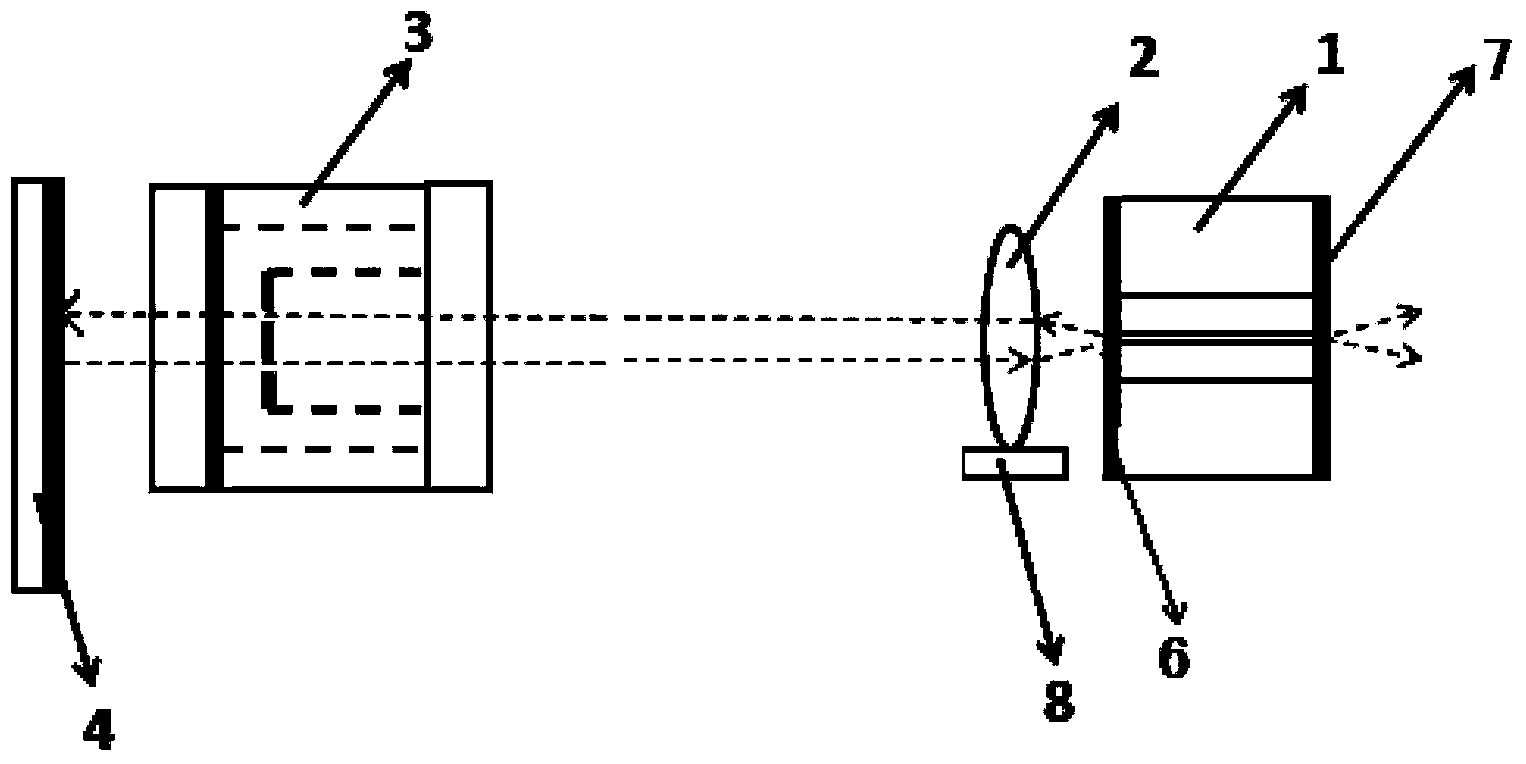

[0028] figure 1 A schematic diagram showing the structure of a wavelength tunable external cavity laser according to an embodiment of the present invention, which includes a laser gain chip 1, and a lens unit 2 that is located on one side of the laser gain chip 1 and constitutes an external cavity feedback area, and an optical etalon 3 and reflector 4, wherein the end surface of the laser gain chip 1 facing the external cavity feedback area is coated with an anti-reflection film 6, and the other end surface is coated with a partial transmission and partial reflection film 7; the laser gain chip 1 is coated with an anti-reflection film 6 The lens unit 2, the optical etalon 3 and the reflector 4 are arranged in sequence from one side; wherein, the lens unit 2, the optical etalon 3 and the reflector 4 are arranged so that the external cavity feedback area and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com