Dual-mode ultrasonic linear motor with high speed, high resolution ratio and high driving force

A linear motor, high-resolution technology, used in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., to solve problems such as inability to transmit energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation process of the present invention will be described below in conjunction with the accompanying drawings. For the sake of clarity and simplicity, detailed detailed descriptions of known functions and constructions in the devices described herein will be omitted when it may obscure the subject matter of the present invention.

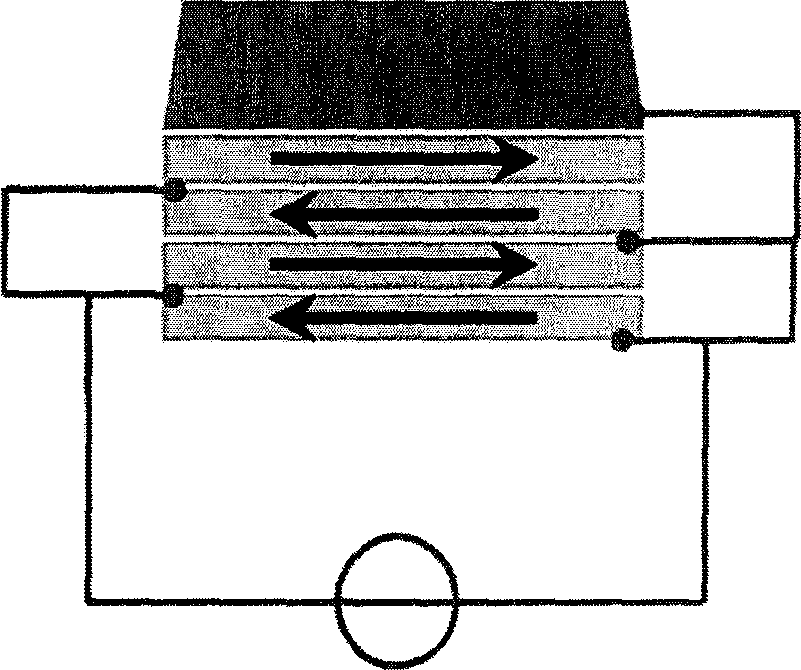

[0013] Such as figure 2 As shown, the most basic driving vibrator unit of an ultrasonic motor is a stack of four piezoelectric ceramic sheets (PZT) arranged alternately in the polarization direction. Due to the characteristics of PZT unidirectional movement, bidirectional movement must be achieved by stacking alternately arranged polarization directions. Driven by positive pulse or negative pulse voltage, two PZTs of the same polarity move in one direction.

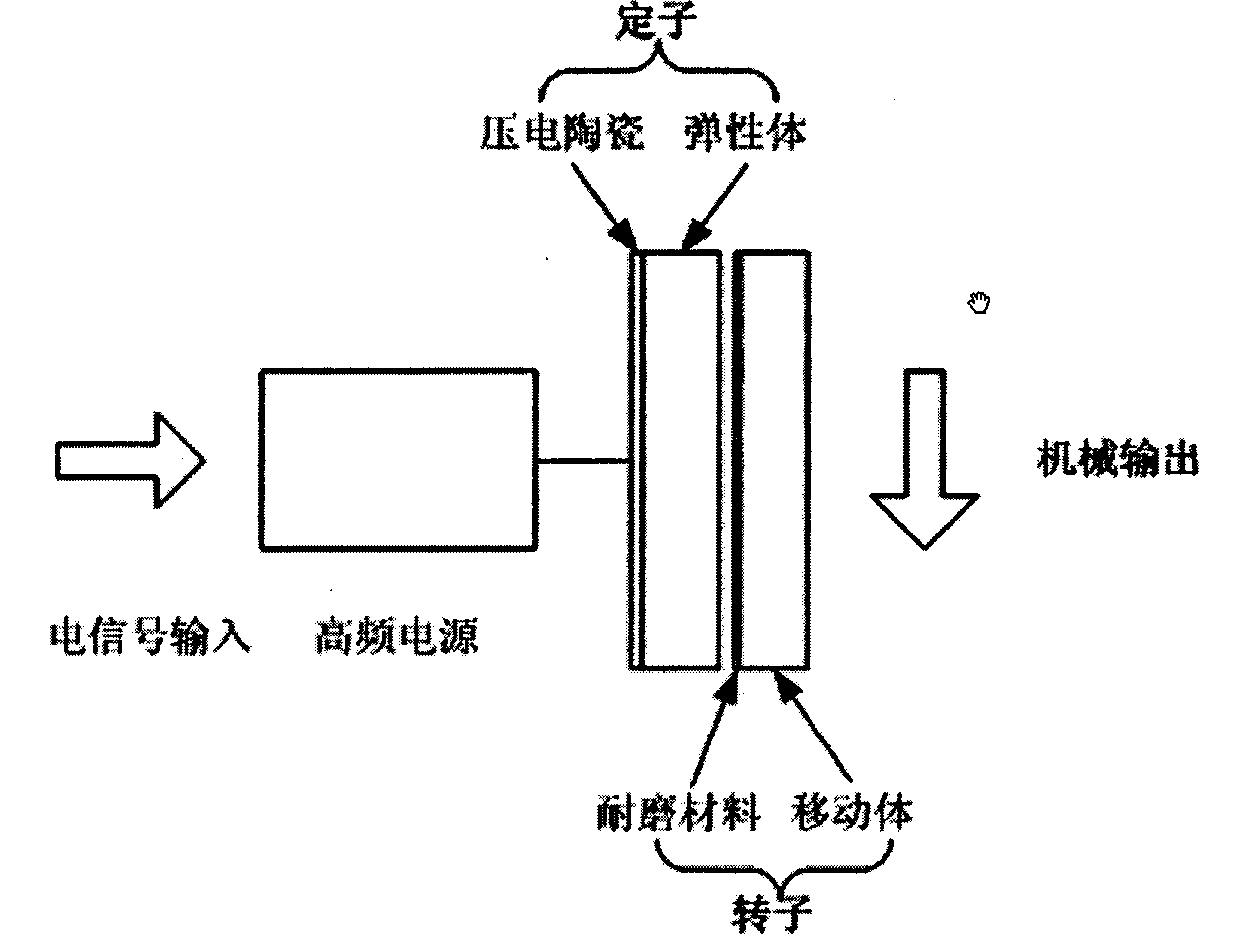

[0014] Such as image 3 As shown, the above 6 identical vibrator units and a total of 24 pieces of PZT are combined to form an array as the driving part of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com