Filtering apparatus

A filtration device and filter technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problem that the effect of hydrodynamically assisted backwashing is not completely satisfactory, the effect of hydrodynamics is limited, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

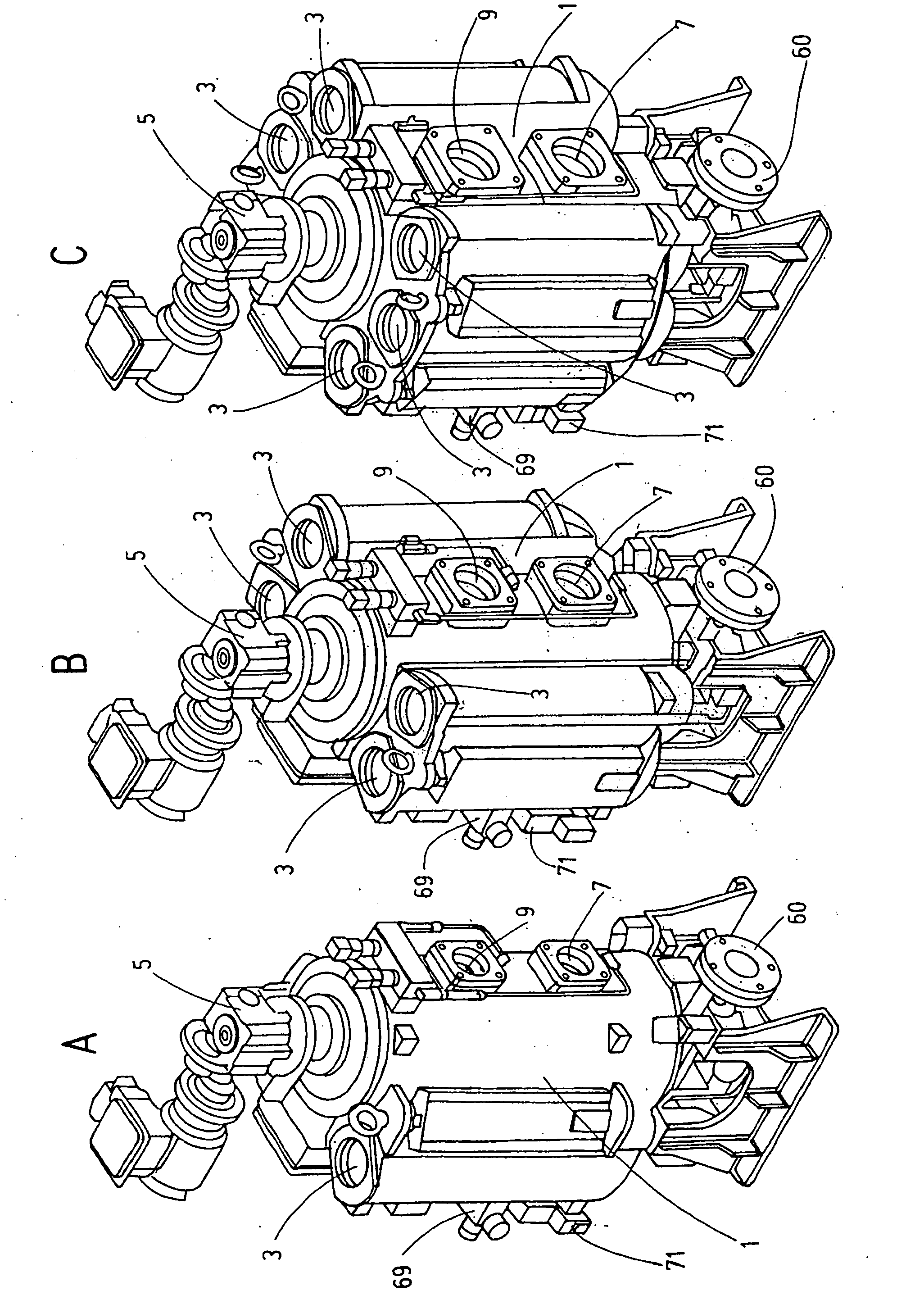

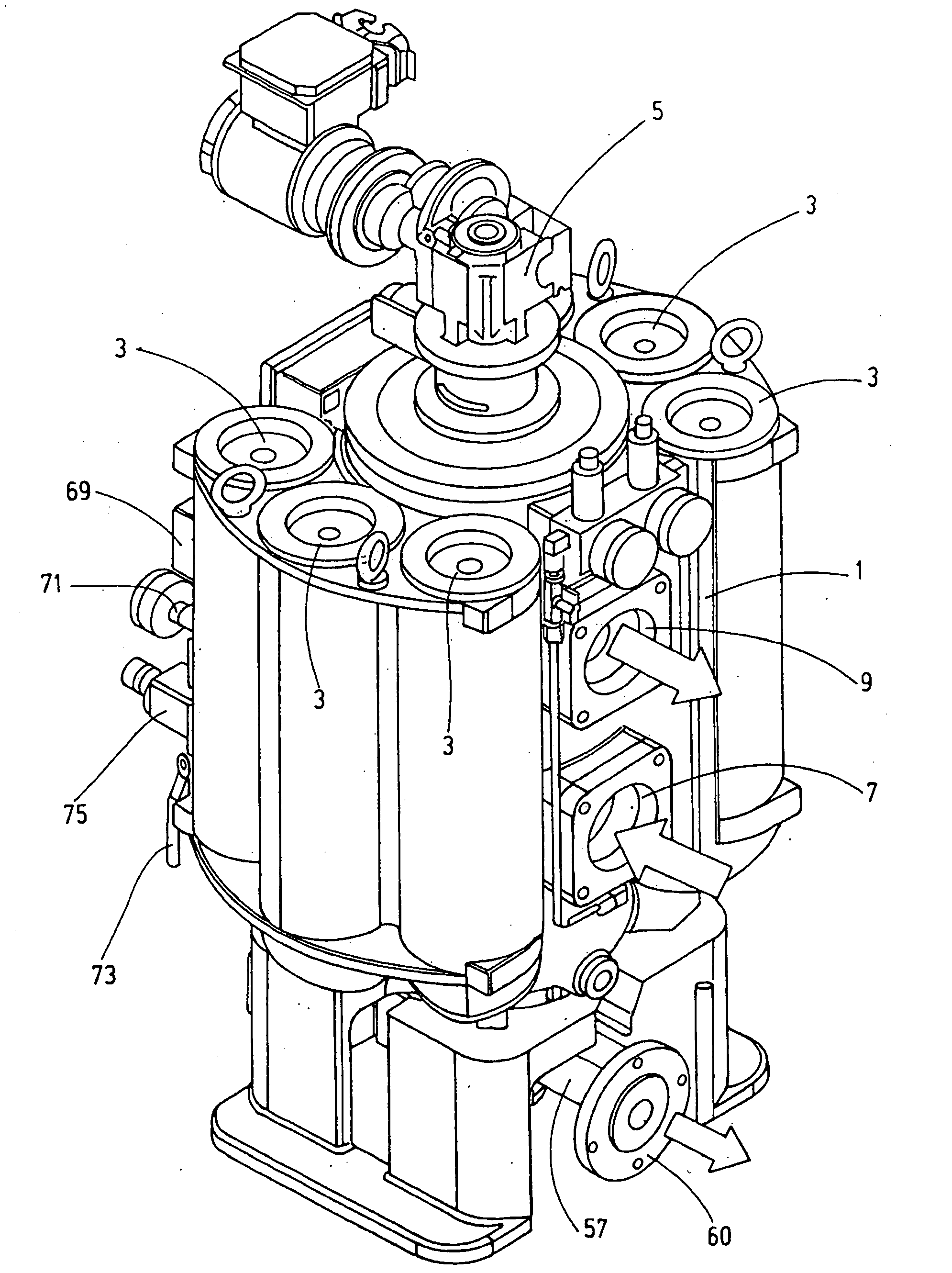

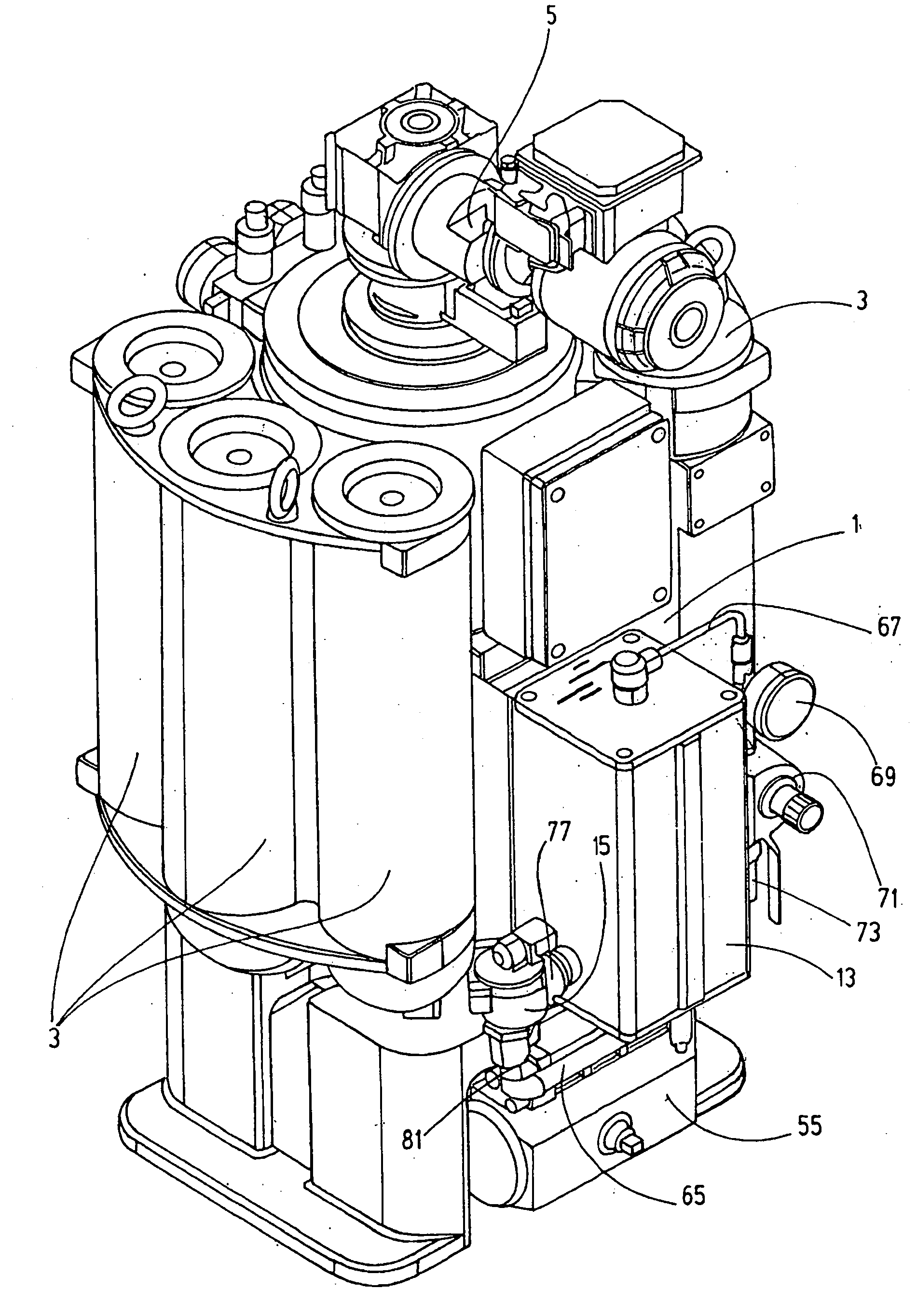

[0029] figure 1 in part figure 1 A to 1C respectively show a general view of the filter device according to the present invention, in figure 1 , the housing body is marked with 1 , the filter element cavity is marked with 3 and the drive part is marked with 5 . The inlet provided on the body 1 for supplying the fluid to be purified is marked with 7 and the outlet for the purified fluid is marked with 9 . figure 1 It has also been shown that the device according to the invention can be designed as a modular building block system for operation with a different number of filter elements. so figure 1 A shows an example with two filter element chambers 3, each of which can accommodate a filter element 11 ( Figure 4 and 5 ),and figure 1 B shows an example with four element cavities 3 and figure 1 C shows an example with six element cavities 3 . A plurality of filter elements 11 can also be arranged in each element chamber 3 , for example in the form of so-called filter cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com