Curtain rail free of length limit, capable of being assembled in site and capable of being opened and closed through electric remote control

An on-site assembly and track technology, applied in the field of building interior decoration, can solve the problems of increasing production costs and transportation costs, troublesome product transportation, inconvenient transportation, etc., to save packaging costs and transportation costs, market prospects, and solve technical defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention will be further described below in conjunction with accompanying drawing:

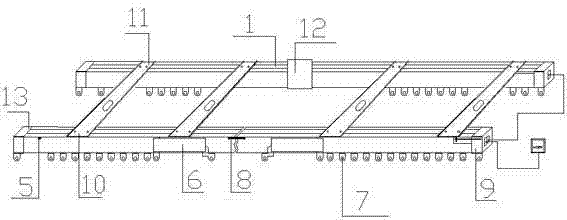

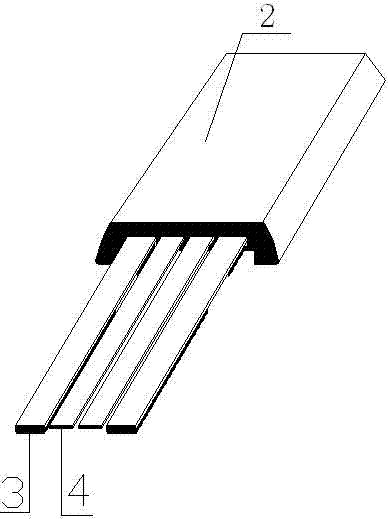

[0026] Such as figure 1 As shown, 1 is the track, 2 is the insertion strip, 3 is the toothed belt, 4 is the power supply steel belt, 5 is the power supply limit press block assembly, 6 is the walking rail, 7 is the pulley, 8 is the intermediate power limit Position pressing block assembly, 9 is power remote control head assembly, 10 is connecting slider, 11 is connecting mounting plate, 12 is decorative hoop, 13 is head, 14 is track shell.

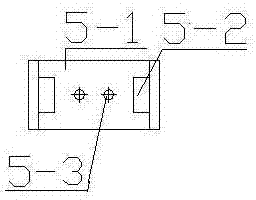

[0027] Such as image 3 , 3-1 , Shown in 3-2, 5-1 is briquetting block, 5-2 is movable block, 5-3 screw.

[0028] Such as Figure 4 , 4-1 As shown, 8-1 is a pressing block, 8-2 is a screw, and 8-3 is a circuit board.

[0029] Such as Figure 5 , 5-1 As shown, 6-1 is a shell, 6-2 is a gear, 6-3 is a limit switch, 6-4 is a small pulley, and 6-5 is a power-taking probe.

[0030] According to the width and length of the windows of ...

Embodiment 2

[0033] Such as Figure 7 As shown, the track shell is a circular pipe, and the track shell is provided with a cutting track groove ( area) and toothed belt track groove ( area), the insert is provided with a steel belt track groove for taking electricity, and the toothed belt is inserted into the toothed belt track groove of the track shell, and other structures are the same as in the embodiment.

Embodiment 3

[0035] Such as Figure 8 As shown, the track shell is a square pipe, and the track shell is provided with an insertion track slot ( area) and toothed belt track groove ( area), the insert is provided with a steel belt track groove for taking electricity, and the toothed belt is inserted into the toothed belt track groove of the track shell, and other structures are the same as in the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com