Ultrasonic atomization generator

An ultrasonic atomization and generator technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of easily damaged vibrating plate 4c, electric corrosion, etc., and achieve the effect of reducing electric corrosion and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

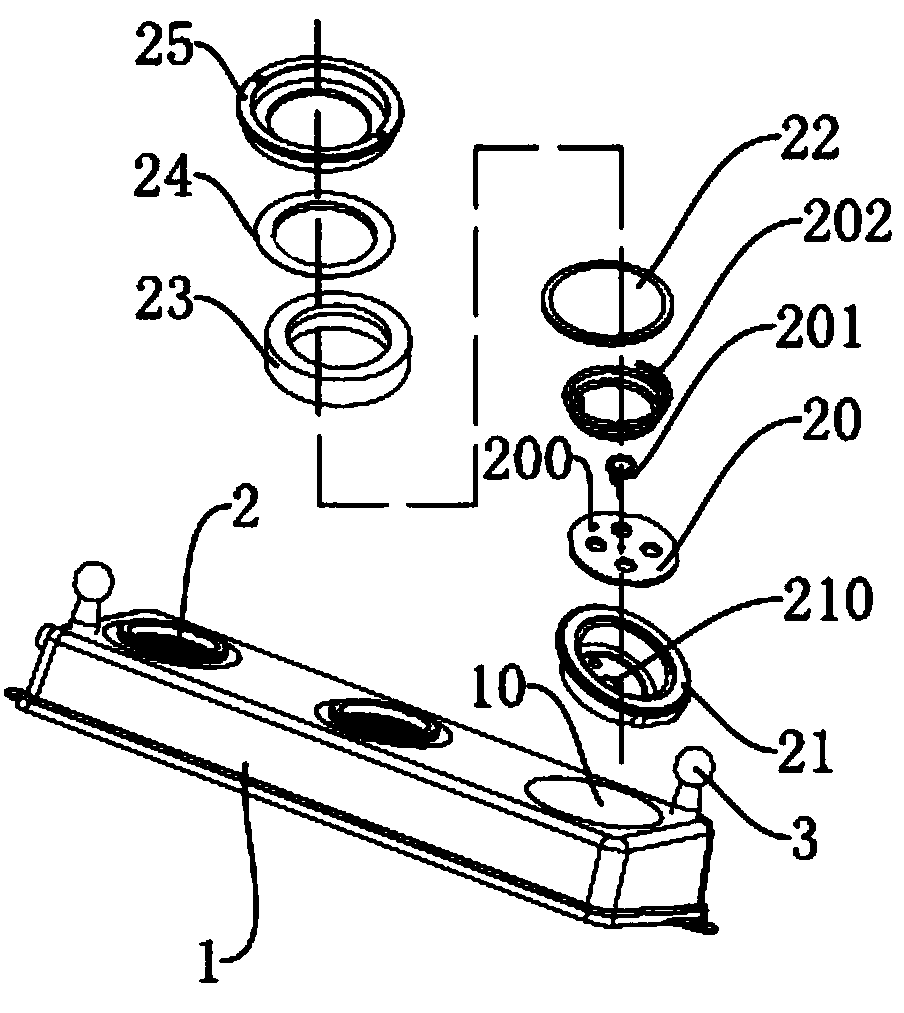

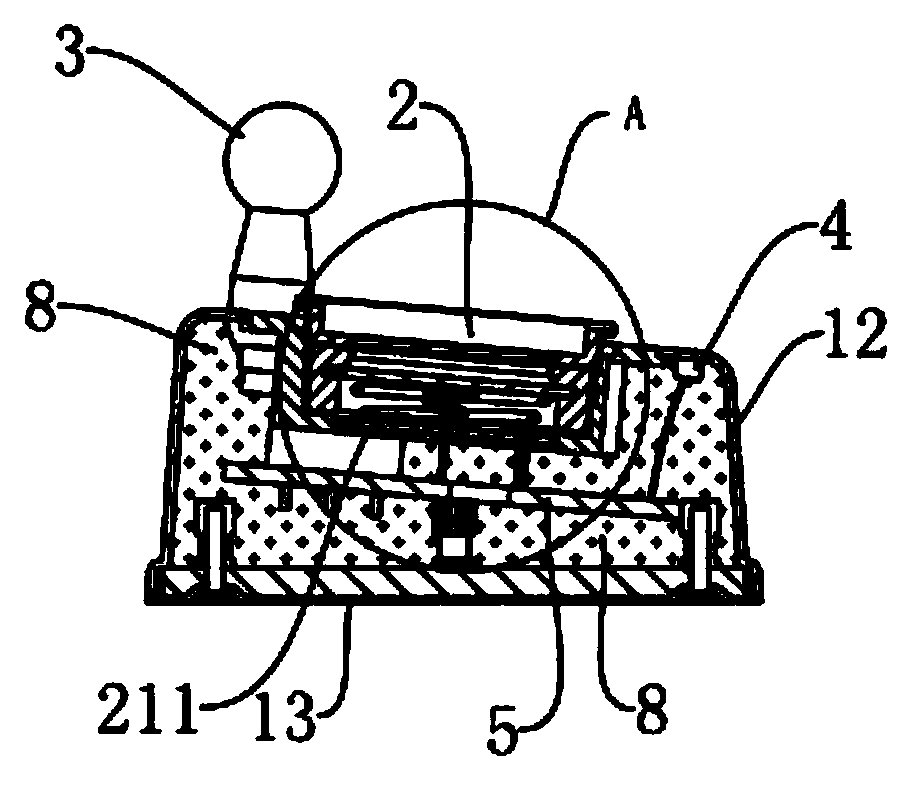

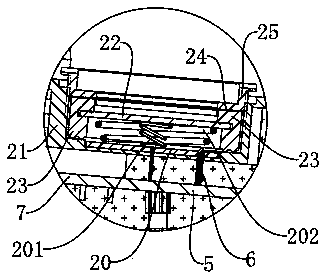

[0024] The ultrasonic atomization generator applying the technical solution of the present invention will be further described below with reference to the accompanying drawings.

[0025] like figure 1 , figure 2 and image 3 As shown, an ultrasonic atomization generator 2 is a device capable of converting high-frequency electrical energy into mechanical energy and atomizing liquids such as water. It includes a unit housing 21 with a cavity, the unit housing 21 is a member with an upper opening, which can accommodate the insulating plate 20, the transducer sheet 22, the first coil conductive spring 201, the second coil conductive spring and other components 202, sealing ring 23, gasket 24, gland 25, etc. The ultrasonic atomization generator 2 is arranged on an outer casing 1 . The outer casing 1 is provided with three casing holes 10 , and the unit casing 21 is embedded in one of them. The outer casing 1 is also provided with a temperature sensor 4 , an electrical lead 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com