Plate-type laminated composite membrane filter core

A composite membrane and filter element technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as large installation space, small water filtration area, and lack of filtration , to achieve the effects of reducing production and use costs, increasing the filtration area, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

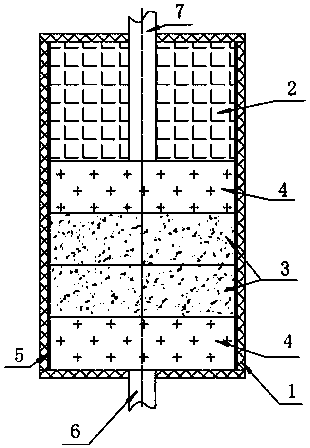

[0019] See attached figure 1 As shown, the plate-type laminated composite membrane filter element of the present invention includes a housing 1 having a raw water inlet 6 and a clean water outlet 7, a filter element is provided inside the housing 1, and a filter membrane element 2 is arranged on the top of the filter element, and the filter membrane element 2 is nanofiltration The membrane element, the filter element includes several layers of activated carbon filter element 3 and PP cotton filter element 4 whose upper and lower positions can be exchanged. The PP cotton filter element 4 is a flat filter element. snug fit. The number of activated carbon filter elements 3 and PP cotton filter elements 4 used and the thickness of the filter layer are determined by the quality of the raw water. In this embodiment, two layers of activated carbon filter elements 3 and two layers of PP cotton filter elements 4 are set inside the shell 1 as an example. In the example, two layers of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com