A novel electronic grade polyimide film with low linear expansion coefficient and its manufacturing method

A technology of polyimide film and low linear expansion coefficient, which is applied in the field of polymer engineering materials, can solve unsolved problems, achieve high industrial application value, improve mechanical properties, and excellent adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

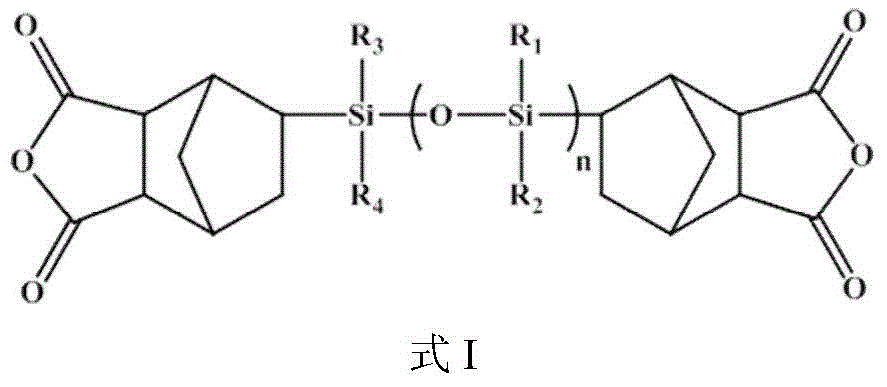

[0042] A method for preparing a polyimide film with a low coefficient of linear expansion, comprising the following contents and process steps:

[0043] (1) Synthesis of step-by-step condensation polyamic acid resin: the present invention uses more than two kinds of diamine monomers and tetracarboxylic dianhydride as raw materials, and adopts the "interpenetrating compound in polymer kettle" technology of multi-stage step-by-step polymerization Synthesis of multi-component block copolymerized polyamic acid resin. That is, the polyamic acid A with the design viscosity is first synthesized by the general polyamic acid synthesis technology, and then another or more diamines and dianhydride monomers are added according to the design molar ratio, and the reaction is carried out for a period of time to obtain the original polyamide A-B-C-… type large block copolymerized polyamic acid in which polyamic acid B is inserted into the molecular chain of acid A. The outstanding advantage ...

Embodiment 1

[0065] Put 500 liters of DMF into the dissolution tank, add 1.00 molar ratio of ODA, start the mixer to stir and dissolve, and the dissolution time is 1 hour. After the diamine monomer is completely dissolved in the polar solvent, stop stirring, and use compressed air to dissolve the diamine monomer. The body solution is pressed into the stainless steel polymerization reaction kettle through the filter, the mixer is started, the cooling water is passed, and then the dianhydride monomer (PMDA, BPDA, BTDA and its composition) is gradually added in 8 times with a total molar ratio of 1.010 to 1.015. . From the 1st to 4th times, the amount of dianhydride added is controlled in equal amounts and at even intervals. A total of 50wt% of the total amount of dianhydride is added in the first 4 times. From the 5th to 8th times, each addition is 50wt% of the total amount of the remaining amount. Putting in, checking the viscosity of the resin after stirring and reacting for 5-10 minutes e...

Embodiment 2

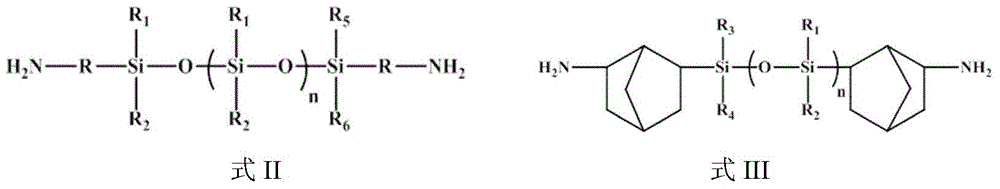

[0068] Example 2 Synthesize the polyamic acid by the block copolymerization of multiple rigid chain acid anhydrides and two or more diamines of ether bonds or siloxane bonds by gradually adding diamine and dianhydride raw materials

[0069] First, the polar aprotic solvent (DMF, DMAc or NMP or any combination of any proportion) that is purified and pre-measured in the solvent tank and whose mass is 3.5 to 7 times the total amount of dianhydride and diamine monomers is put into the dissolution tank 0.50-0.70 molar ratio of ODA and 0.25-0.20 molar ratio of 1,3-bis(3-aminopropyl)tetramethyldisiloxane (APDS) were put into it through the automatic metering system, and the mixer was started to stir and dissolve , the dissolution time is not less than 1.5 hours. After the diamine monomer is completely dissolved in the polar solvent, stop stirring, and add 0.65-0.75 molar ratio of PMDA to the polymerization kettle in 5 batches at intervals of 10-30 minutes. After completion, continue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com