PVC (polyvinyl chloride) combination for storage battery shell and preparation method thereof

A technology of polyvinyl chloride and battery, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high cost, large amount of heat-resistant modifier, low impact strength, etc., and achieve excellent impact performance, strong resistance Oxygen aging performance, the effect of superior heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

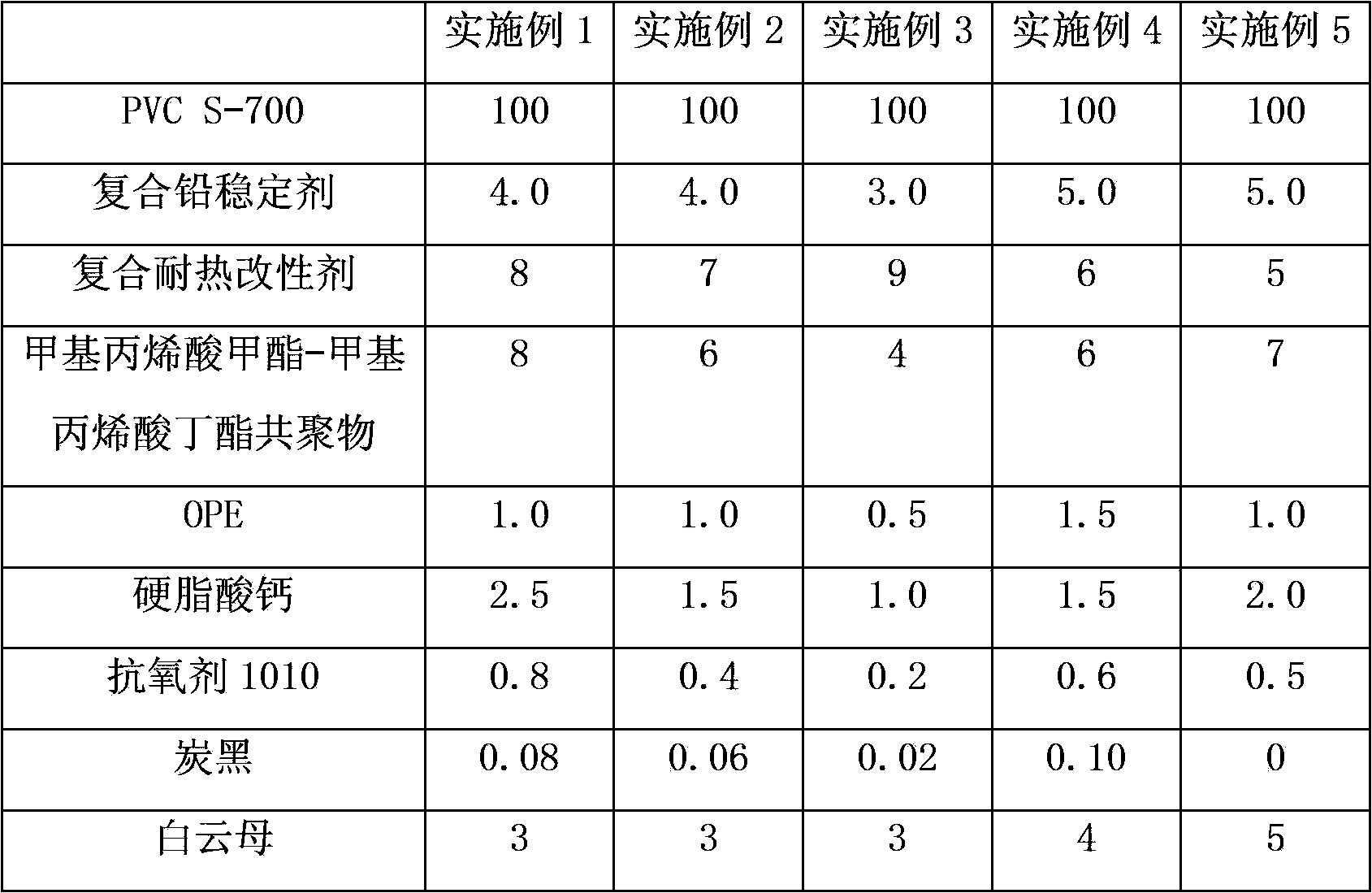

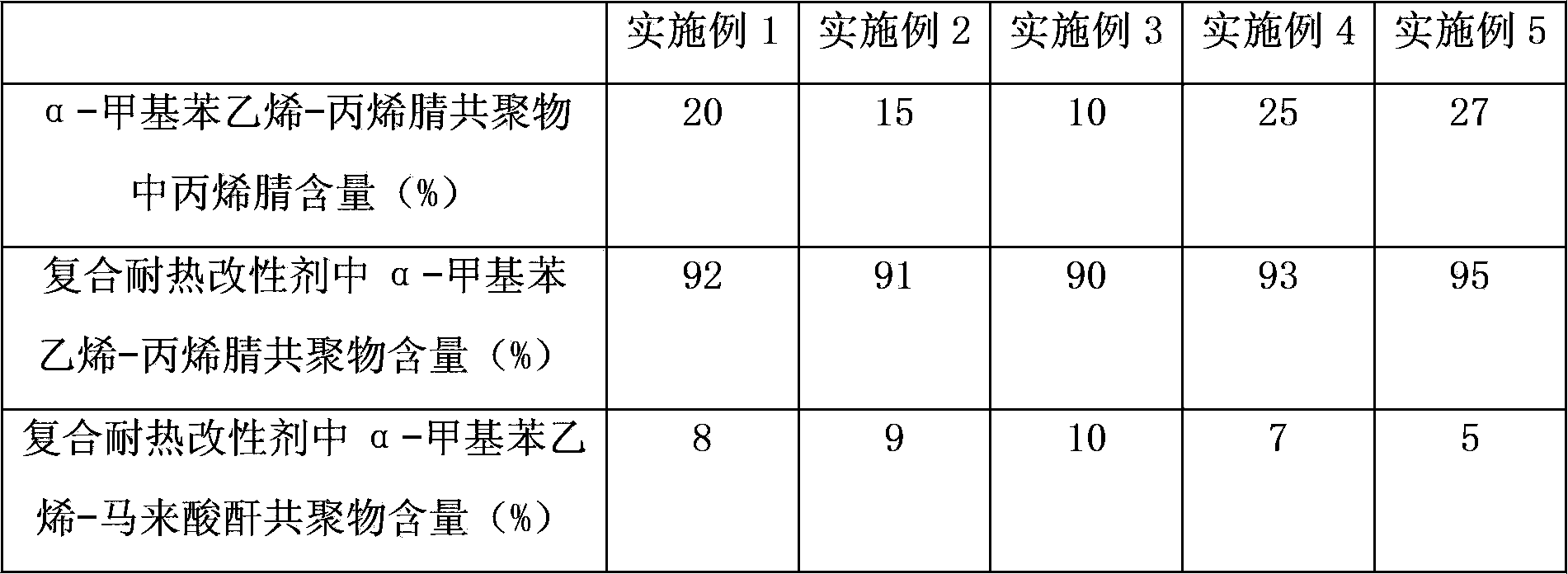

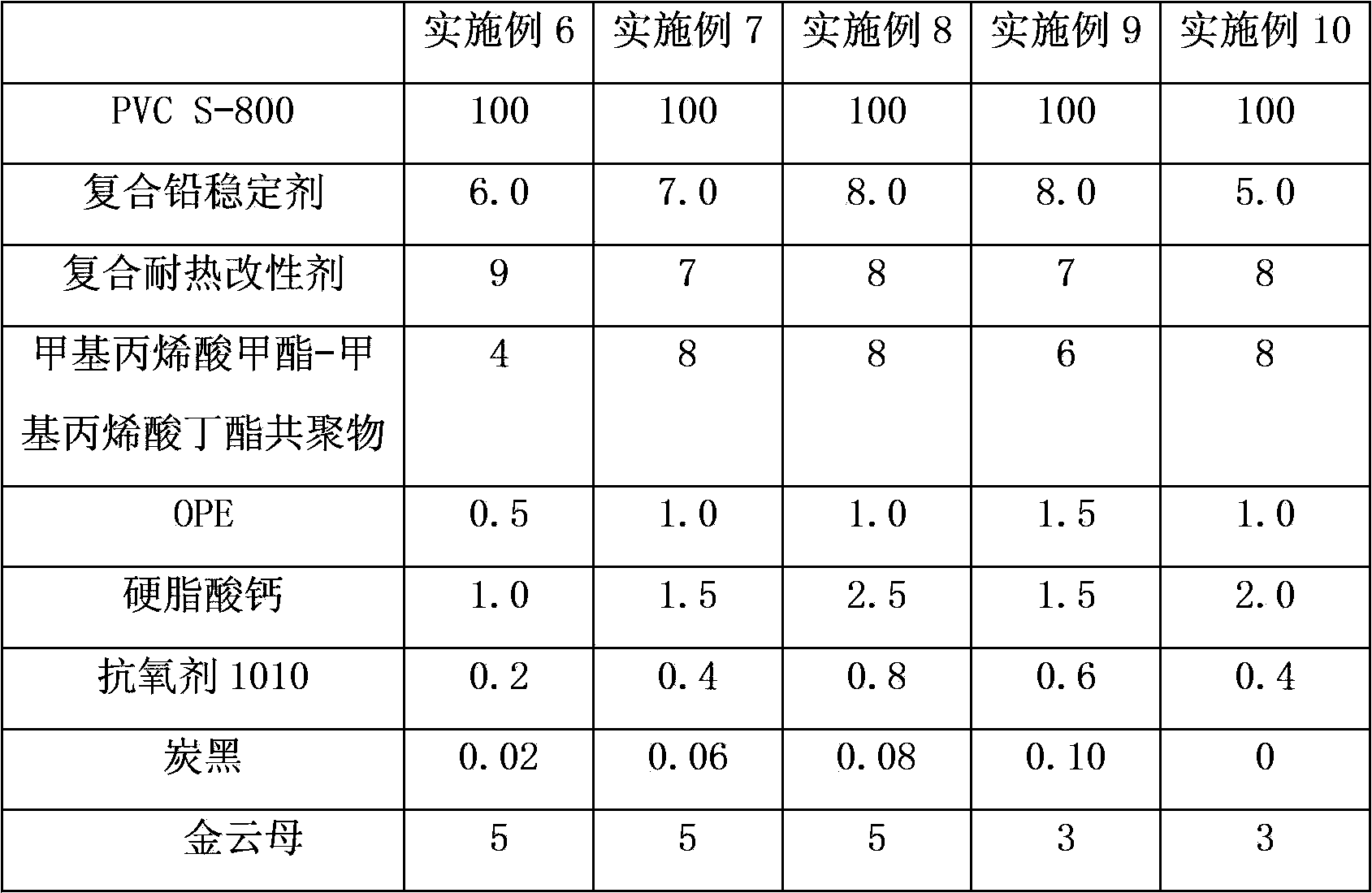

Examples

Embodiment

[0035] Embodiment preparation method:

[0036] (1) Mixing of raw materials: Weigh the materials of Examples 3-8 according to the ratio of raw materials, then add them to a high-speed mixer and mix until the mixing temperature is 115°C, put the materials into a low-speed mixer, and wait for the temperature of the materials to cool to 40°C Time to discharge.

[0037] (2) Special material granulation process: The mixed material is granulated by twin-screw, and the process parameters are set as follows:

[0038] Table 5: Process parameters of twin-screw granulator

[0039]

zone 1

Zone 2

District 3

District 4

District 5

Extruder temperature (°C)

120

130

135

140

145

145

[0040] The preparation method of embodiment 1, 2 is the same as embodiment 3~8, and difference is that mixing temperature is 100 ℃, and discharge temperature is 37 ℃;

[0041] The preparation method of embodiment 9,10 is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com