lpcvd automatic water replenishment system

A technology of automatic water replenishment and water replenishment device, applied in the field of water replenishment system, can solve the problems of reducing membrane production efficiency and yield, deterioration of membrane physical properties, unfavorable enterprise development, etc., to promote healthy development, low production and processing costs, The effect of improving production efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

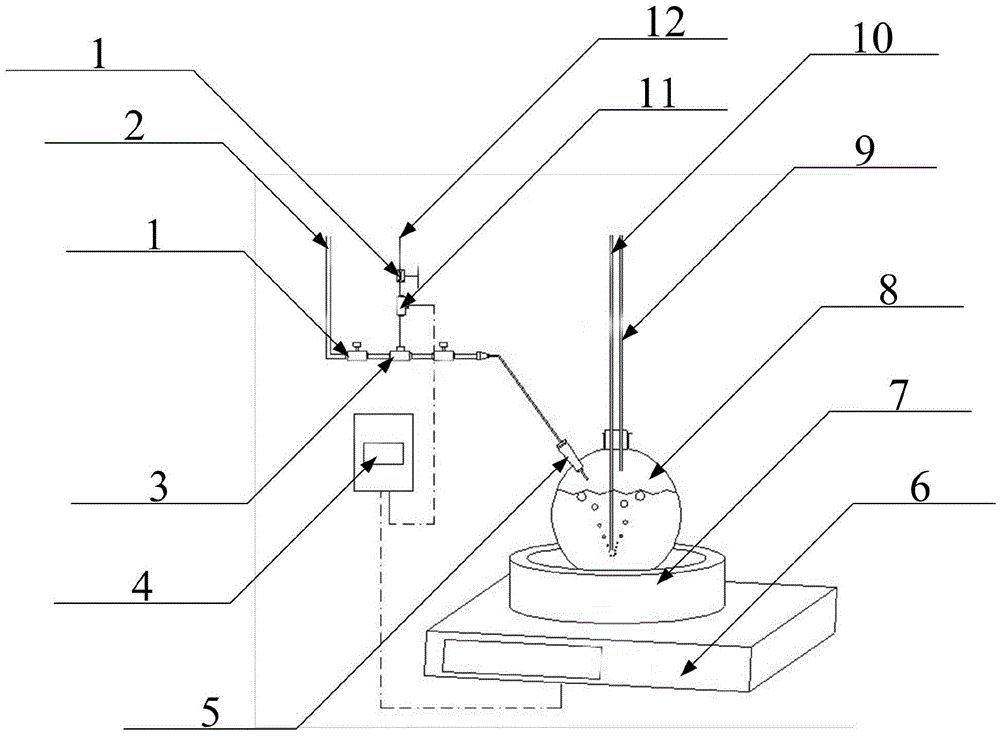

[0018] Such as figure 1 As shown, the LPCVD automatic water replenishment system includes wet oxygen SiO Process furnace tube, which is connected with a water replenishment system on the wet oxygen SiO Process furnace tube; the water replenishment system includes a water storage tank 8, which passes through a water vapor output pipe 9 is connected with the wet oxygen SiO2 process furnace tube, and a high-purity nitrogen input pipe 10 is also arranged at the upper end of the water storage tank 8, and a water inlet 5 is also arranged on the water storage tank 8, and a water supply device is installed on the water inlet 5, and the water storage tank A heater 7 is arranged below the water tank 8, and a gravity control device is also arranged on the heater 7, and the gravity control device is connected with the water supply device.

[0019] The above-mentioned replenishing device includes a water inlet pipe 2, which is fixed on the water inlet 5 at the end of the water inlet pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com