Combined steel rib-embedded concrete-filled steel tube column with irregularly-shaped section

A technology of steel pipe concrete and special-shaped cross-section, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of heavy welding workload, high construction difficulty, unfavorable work efficiency, etc., achieve good bending resistance and fire resistance, and obvious restraint effect , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

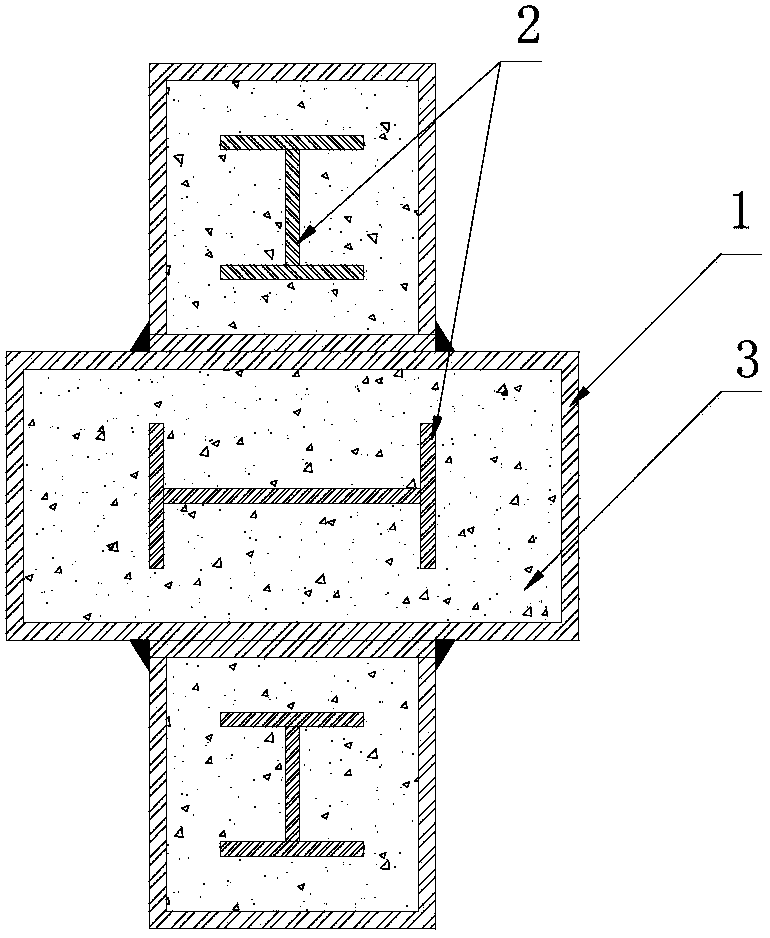

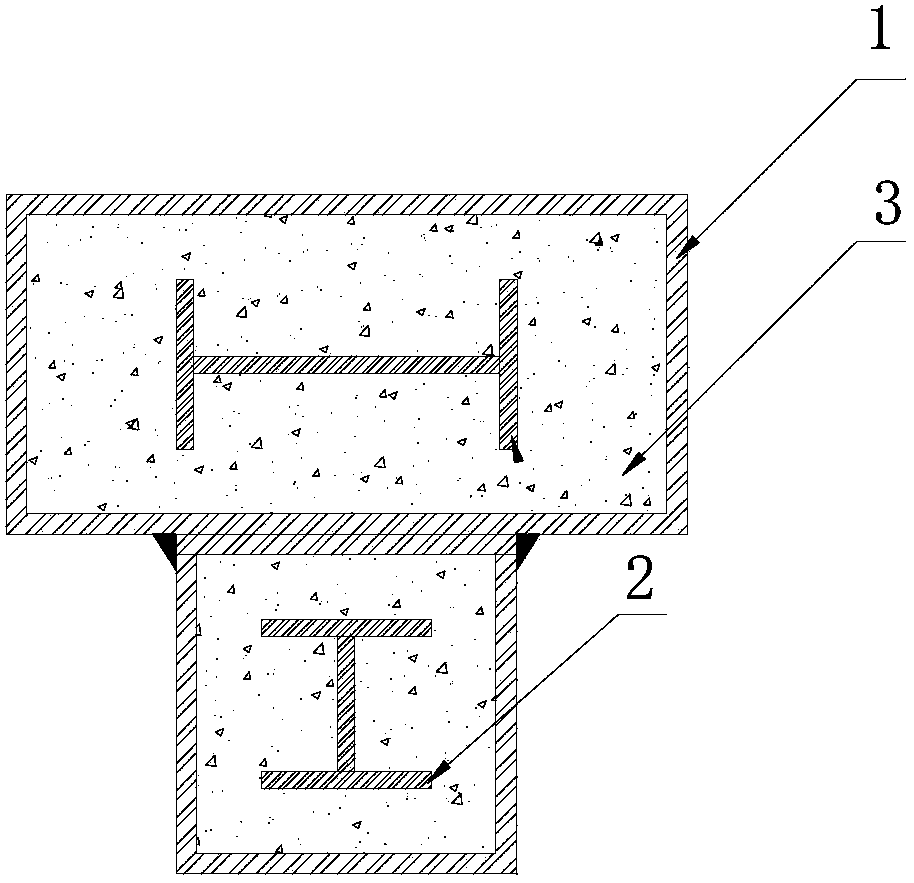

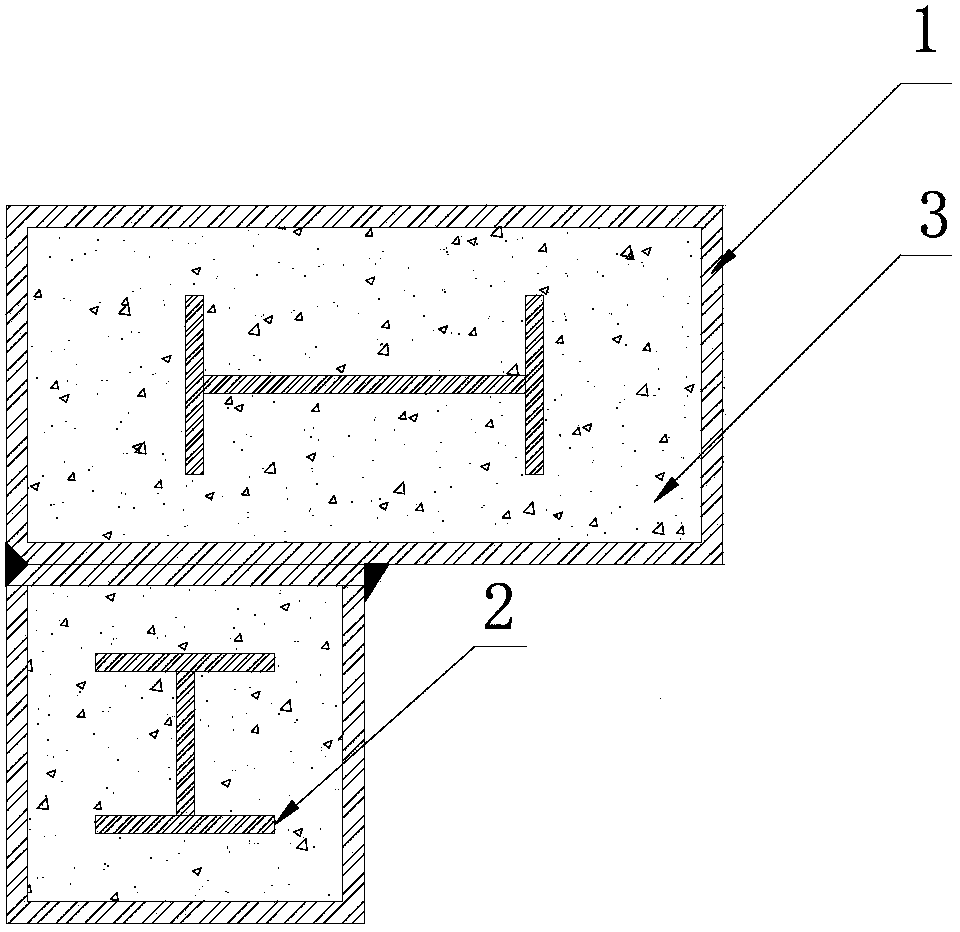

[0013] A special-shaped steel tube concrete composite column with built-in steel frame in the present invention is composed of steel tube 1, steel frame 2 and concrete 3; the composite column is formed by connecting two or three steel tubes 1 through fillet welds; The steel frame 2 is provided, and the symmetry axis of the steel frame 2 coincides with the symmetry axis of each sub-steel tube 1; the concrete 3 is filled between the steel tube 1 and the steel frame 2; the cross-sectional form of the composite column can be "ten" , "T" shape or "L" shape; steel pipe 1 can be rectangular steel pipe, square steel pipe, or "U" shaped steel pipe; steel frame 2 can be "I" shaped steel, or "ten" shaped steel Steel; the concrete 3 filled inside can be ordinary concrete, high-strength concrete, recycled concrete or self-compacting concrete.

[0014] When imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com