Shield underwater oblique crossing hole entering construction method

A construction method and tunneling technology, which can be applied to earth drilling, mining equipment, tunnels, etc., and can solve the problems of large water and sand gushing risks during shield tunneling construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

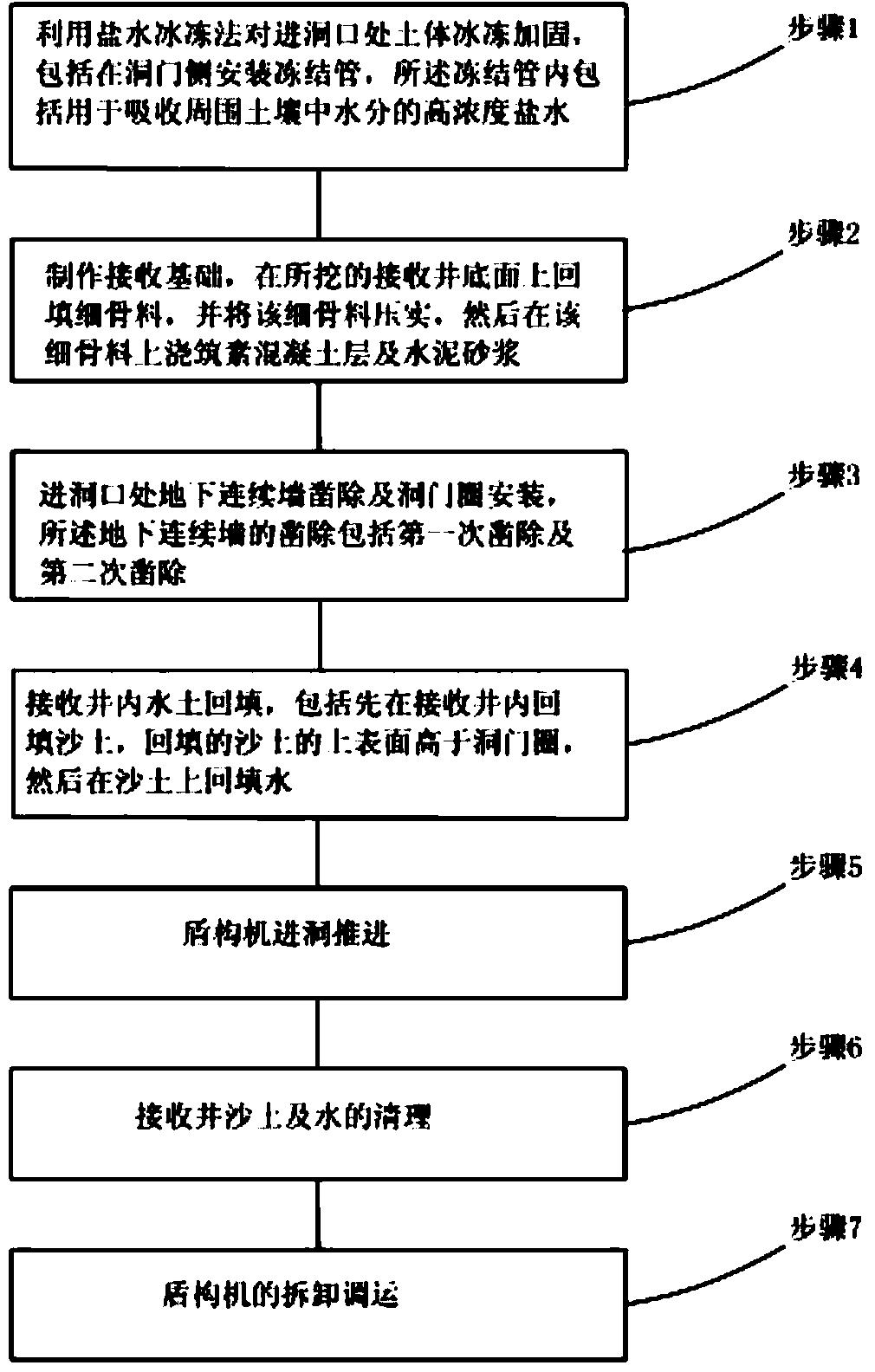

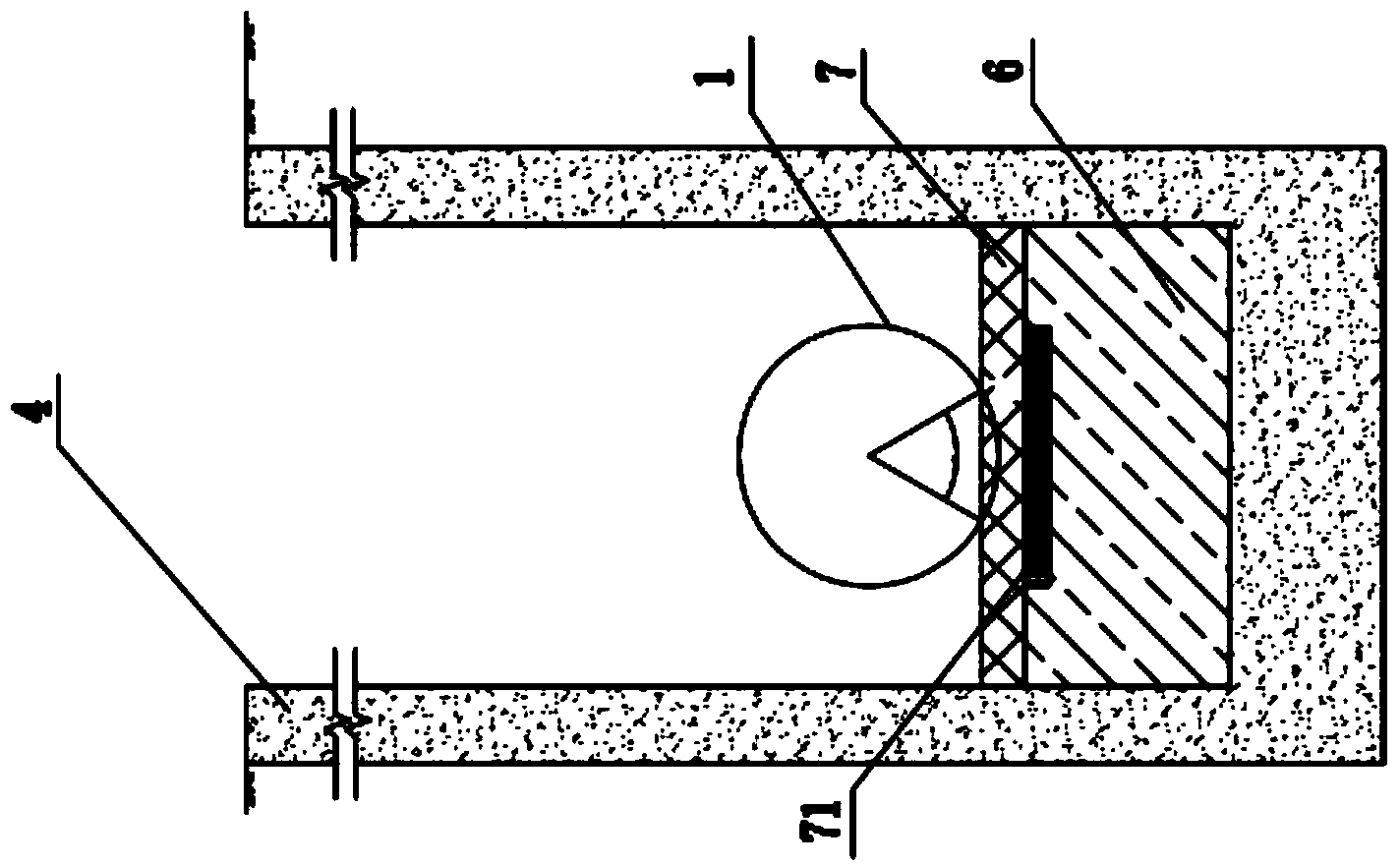

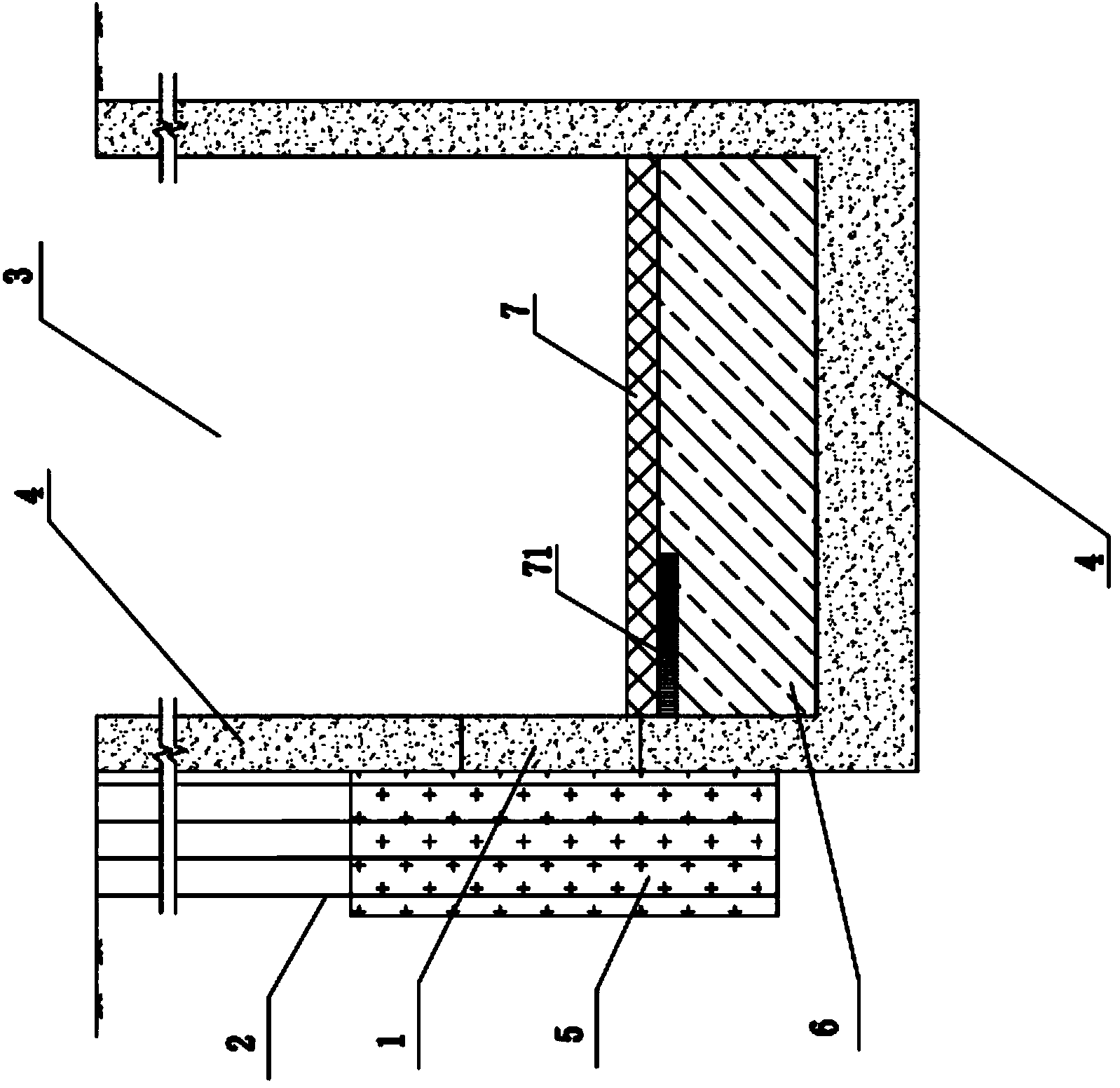

[0038] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0039] This specific embodiment takes the tunneling construction of a shield tunnel as an example. The project is a shield tunnel with a small curvature radius. When the shield tunneling is tunneled, there is a horizontal inclination angle of 16.5° between the tunnel axis and the underground diaphragm wall of the receiving shaft wall. The tunneling construction In the state of deep covering soil, high water pressure, complex stratum, etc., there is a greater risk of water and sand gushing. In order to ensure the smooth entry of the shield tunnel, the construction method of underwater oblique tunnel entry was adopted comprehensively considering the characteristics of the stratum and engineering characteristics. The construction process has prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com