Construction method for connection passage by double-row hole horizontal freezing method

A technology for connecting channels and construction methods, applied in infrastructure engineering, tunnels, earthwork drilling and mining, etc., can solve the problems of long construction period, difficult construction, low efficiency, etc., and achieve the effect of shortening the construction period, improving freezing efficiency, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0060] Concrete embodiment connection channel (2):

[0061] The net distance of connecting channel (2) is 15.199m, and the height difference between tunnels is 0.017m. The construction process is as follows:

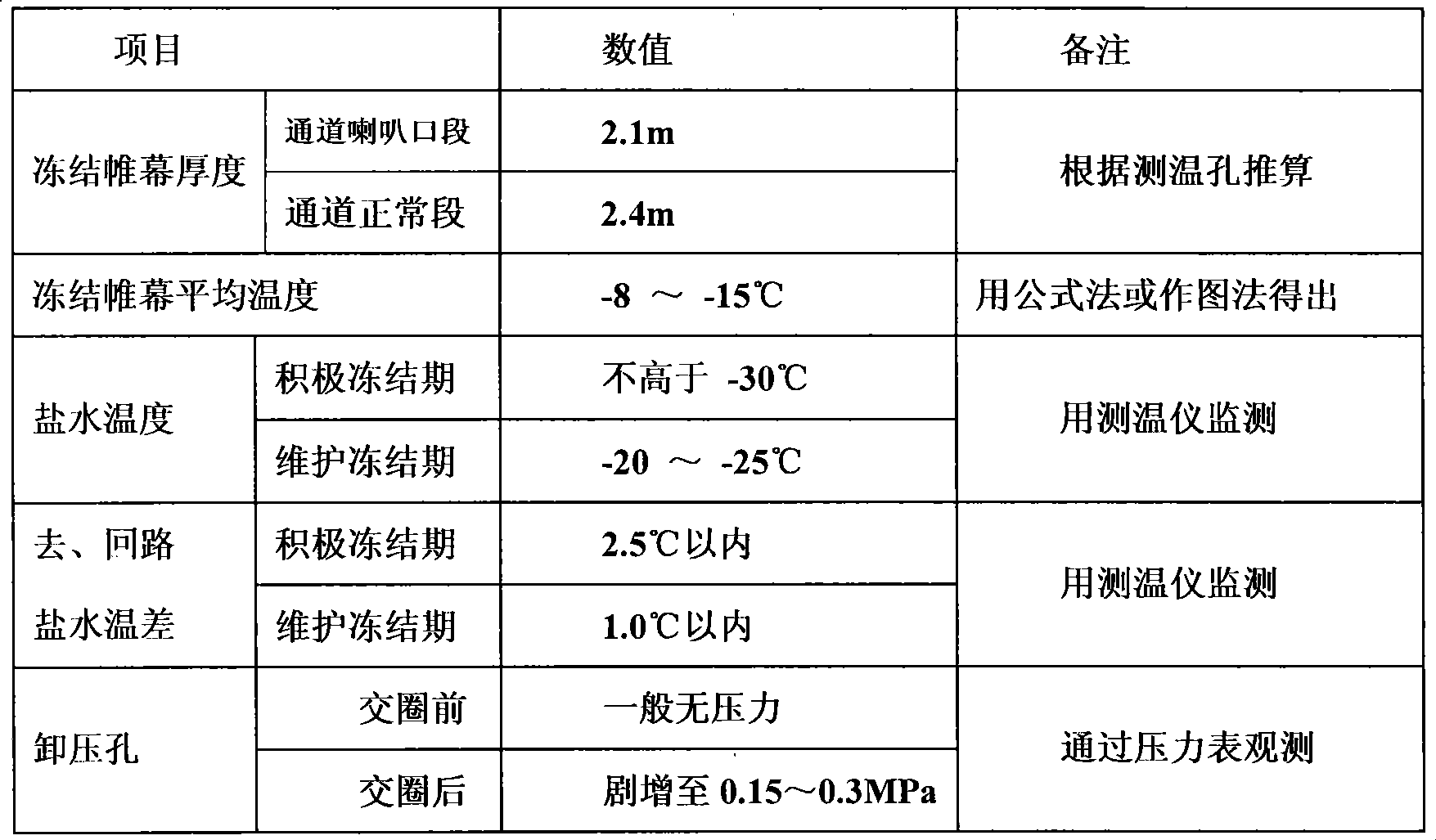

[0062] (1) Determine the construction parameters of the freezing method

[0063] ①Frozen brine temperature: active freezing period: not higher than -30°C,

[0064] Maintenance freezing period: -20℃~-25℃;

[0065] ②Average temperature of freezing curtain: -8℃~-15℃;

[0066] ③ Freezing curtain strength: δ 压 =4.95MPa; δ 拉弯 =2.7MPa; δ 剪 =2.4MPa;

[0067] ④ Thickness of the freezing curtain: 2.4m for the normal section of the connecting channel, and 2.1m for the bell mouth section of the connecting channel.

[0068] (2) Arrangement of freezing holes

[0069] ①Main parameters of freezing hole

[0070] Freezing hole spacing: The freezing holes are arranged according to the plane size and force characteristics of the connecting channel and the principle of avoiding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com