A self-priming device for a centrifugal pump

The technology of self-priming device and centrifugal pump is applied to the components, pump, driving pump and other directions of pumping device for elastic fluid, which can solve the problems of increasing the difficulty of control operation, occupying space, and increasing the axial length of the pump body, etc. Achieve the effect of avoiding unstable work, simple and compact overall structure, and ensuring work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

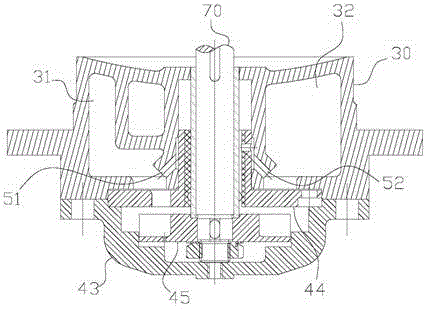

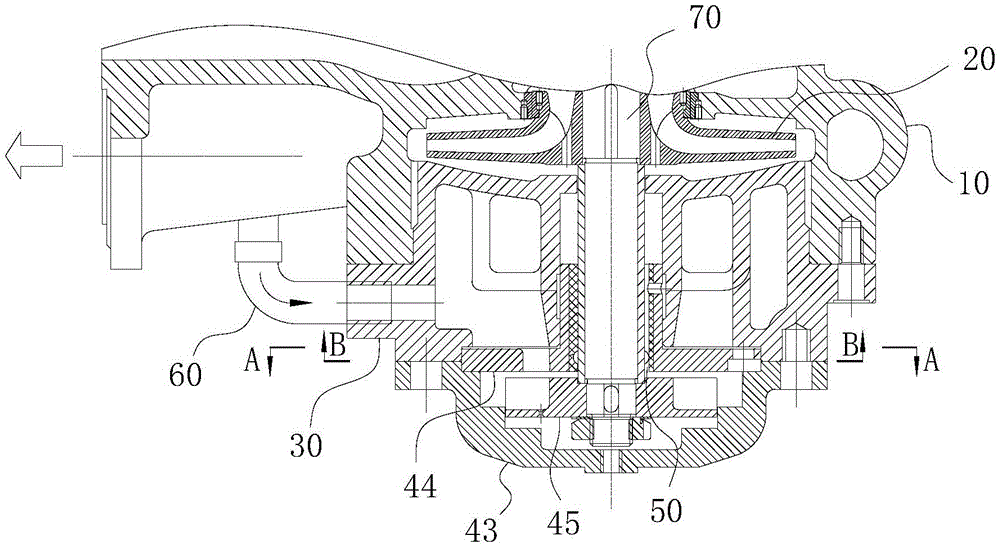

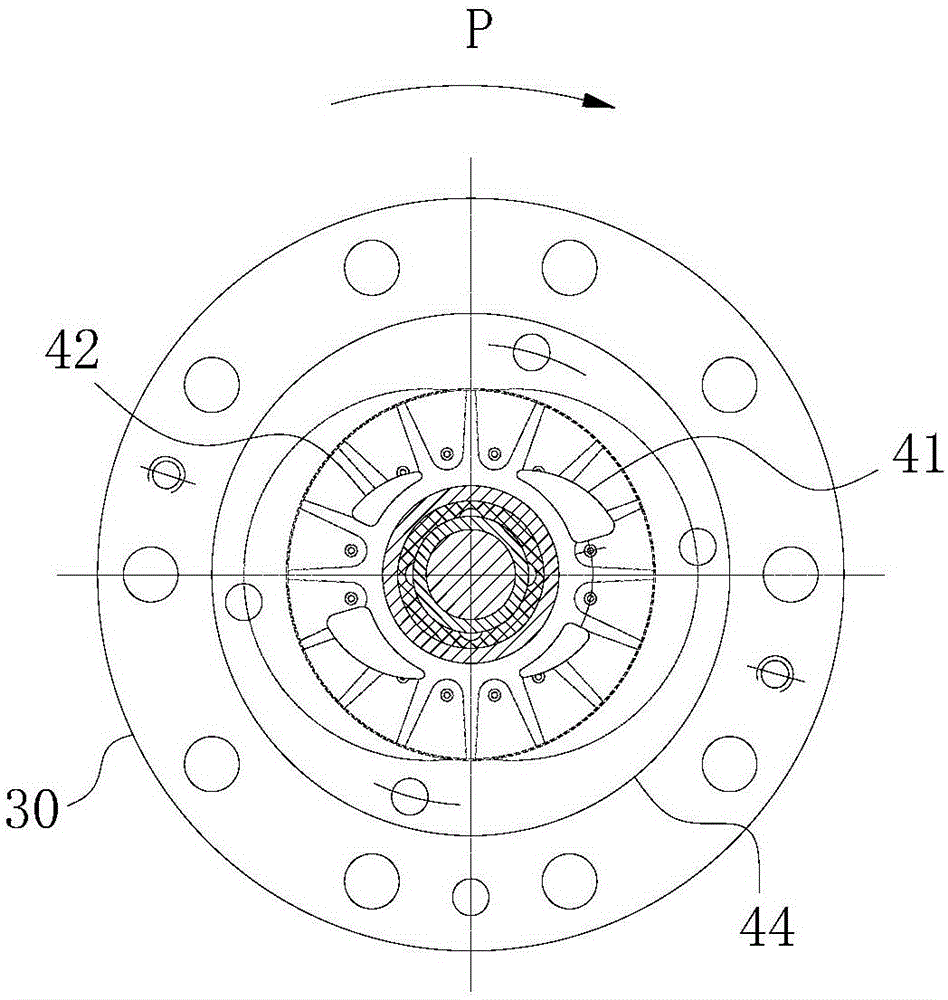

[0027] For ease of understanding, the following combination Figure 1-4 Concrete structure and workflow of the present invention are described as follows:

[0028] Such as figure 1As shown, the present invention includes a vacuum pump, a pump body 10 and a pipeline 60 . The vacuum pump and the pump body 10 are sequentially connected in series through the integrated pump shaft structure 70 formed by the pump shaft and the rotating shaft, that is, after the head end of the integrated pump shaft structure 70 is connected to the aforementioned driving end, it is then extended from the pump body 10 The middle part of the pump chamber passes through and is fixed by the spacer 30. The tail end of the integrated pump shaft structure 70 constitutes the rotating shaft of the vacuum pump so as to be fixedly connected to the self-priming impeller 45, and the shaft between the head end and the middle part of the integrated pump shaft structure 70 The shaft forms a fixed section of the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com