Combustion radiator of blast rotation pre-mixed porous medium gas stove and combustion method thereof

A technology of porous media and rotary mixer, which is applied in the direction of combustion method, gas fuel burner, burner, etc., can solve the problems of reducing combustion efficiency and thermal efficiency, difficult to mix, incomplete combustion, etc., to improve thermal efficiency and combustion efficiency, The effect of reducing pollutant emissions and enhancing combustion intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

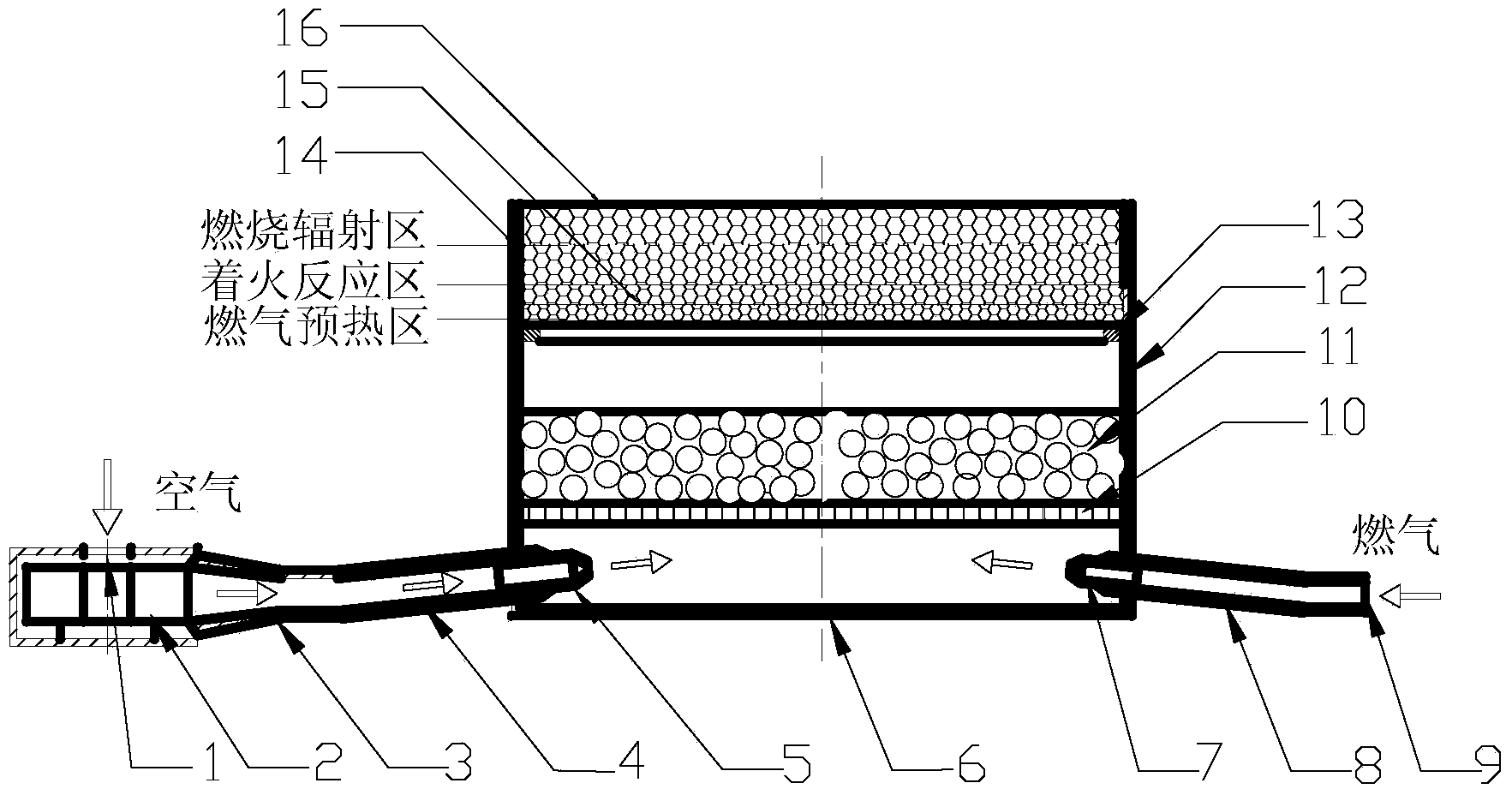

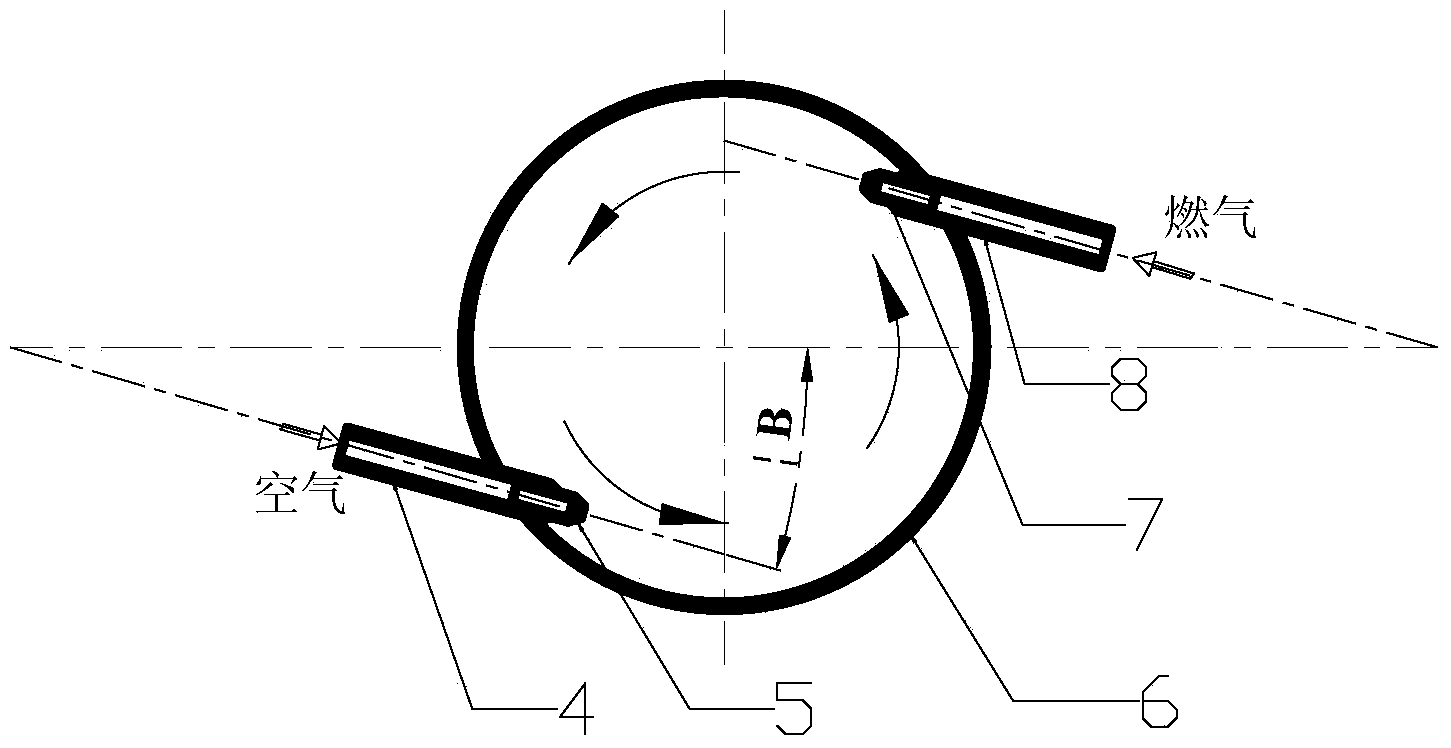

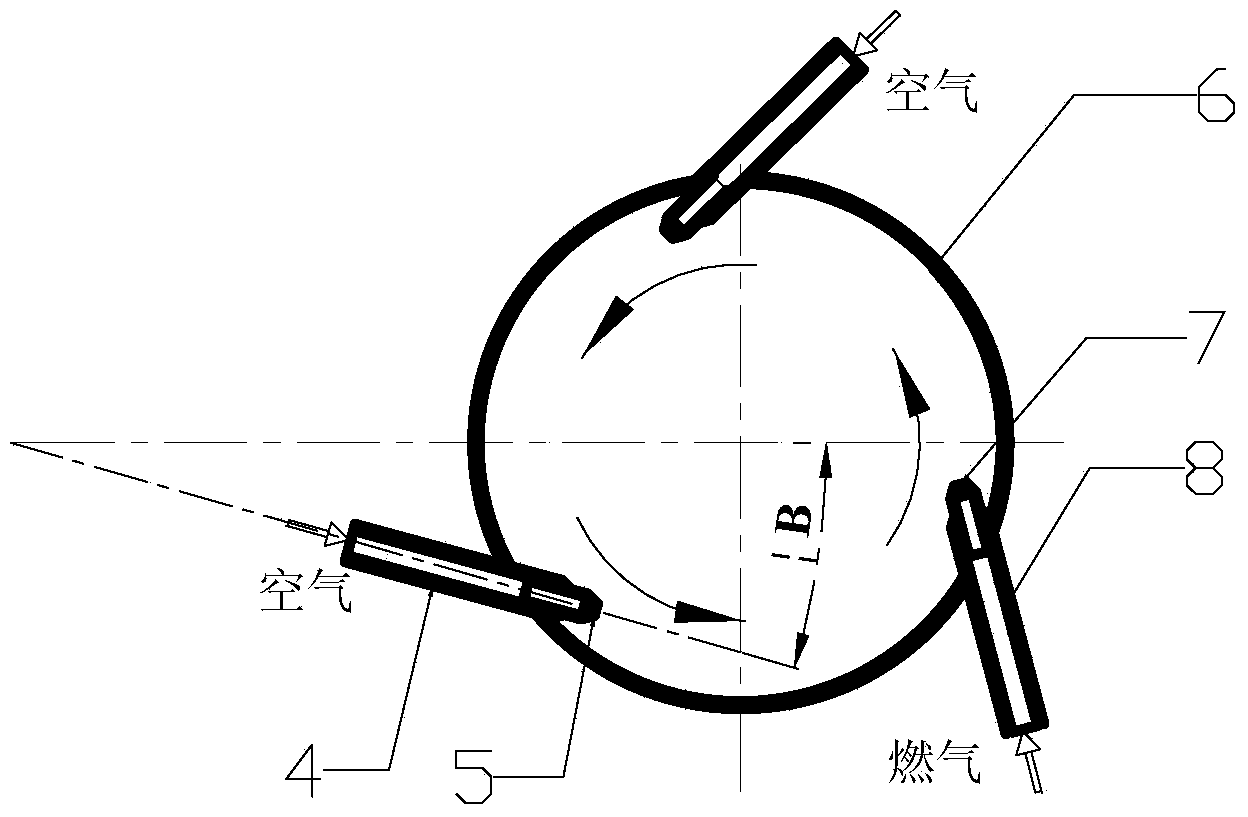

[0024] Such as figure 1 As shown, the device of the present invention includes a blower fan 2, a rotary premixer 6, an air injector 5 and a gas injector 7 are respectively provided on the side of the middle and lower end of the rotary premixer 6, and the upstream of the air injector 5 passes through an air duct 4 It is connected with the fan outlet 3, and the fan has an air inlet 1; the gas inlet 9 is introduced into the gas injector 7 through the gas pipeline 8, and a gas flow uniform distributor 10 is provided above the gas rotary premixer 6, and a gas flow uniform distributor 10 is provided above the gas flow uniform distributor 10. A porous medium premixer 11 , a gas stabilizing chamber 12 is arranged above the porous medium premixer 11 , and a porous medium combustion radiator 14 is arranged above the gas stabilizing chamber 12 via a support frame 13 . The tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com