Experimental device for evaporating and igniting droplets under high-temperature high-pressure environment and use method thereof

A high-temperature, high-pressure, droplet evaporation technology, applied in the direction of material thermal development, etc., can solve the problems of engine combustion conditions gap, liquid droplets affect the experimental results, and can not be obtained, so as to achieve the effect of saving electric energy, high experimental accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

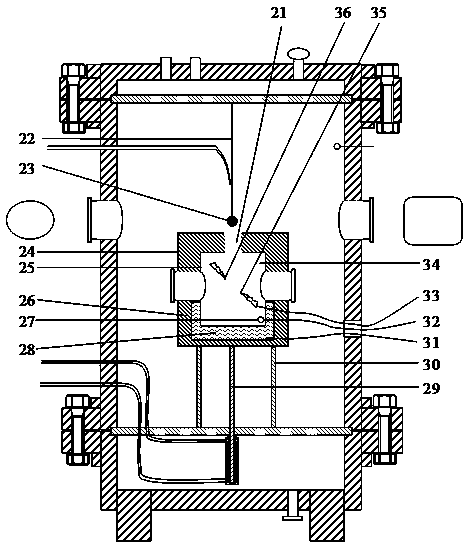

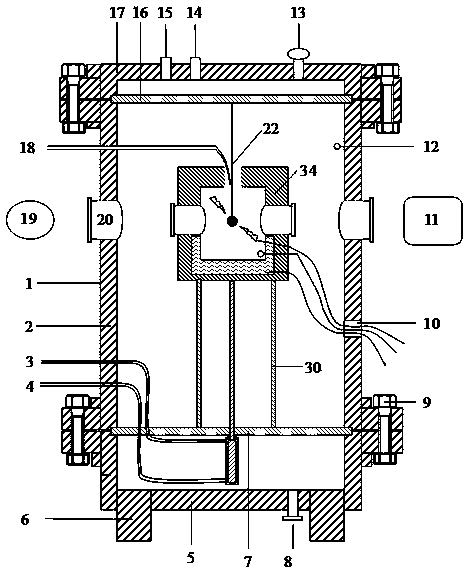

[0028] Such as figure 1 and figure 2 As shown, a liquid droplet evaporation ignition experimental device under high temperature and high pressure environment includes a closed pressure vessel 1 surrounded by an upper cover 17, a lower cover 5 and a side plate 2, and an electrically heated high temperature combustion chamber placed inside it. 34 and an ignition device arranged in the high-temperature combustion chamber 34 for igniting the liquid droplets 23, the ignition device includes an electric spark plug 35 and a tungsten wire 36 arranged oppositely. The above-mentioned upper cover 17, lower cover 5 and side plate 2 can be an integral structure, wherein the side plate 2 can open the door; it can also be connected by a plurality of bolts 9; in addition, the shape of the airtight pressure vessel 1 and the high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com