Multi-eye vision guidance driving device for automatic guided vehicle and its collaborative calibration method

A technology of automatic guided vehicles and driving devices, applied in two-dimensional position/channel control, image data processing, instruments, etc., to achieve the effect of eliminating distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

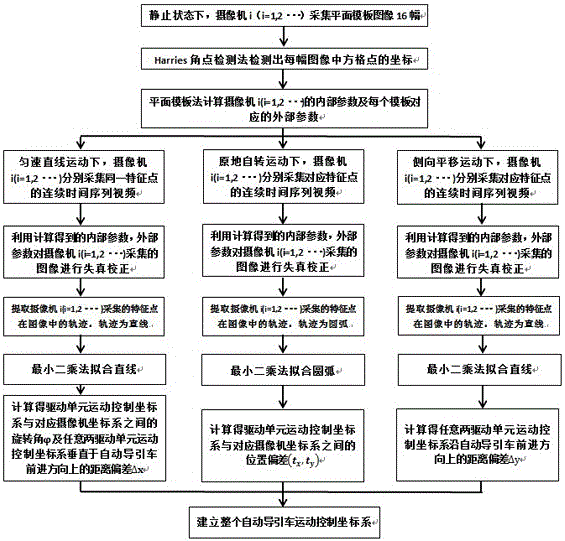

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

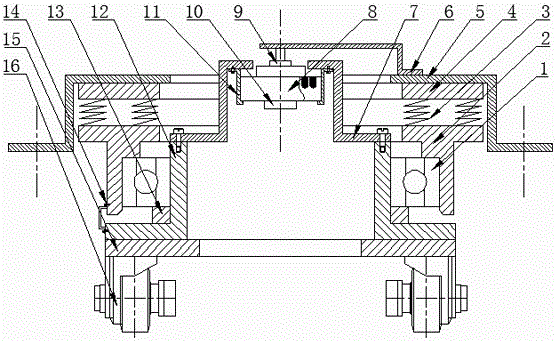

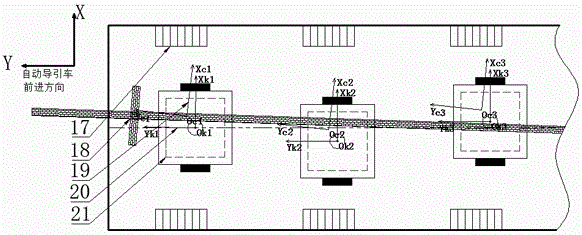

[0041] The structure of the visual guidance driving device provided by the present invention is as follows: figure 1 shown. The visual guidance driving device is fixedly connected to the body of the automatic guided vehicle through a fixed plate (5). Each device includes a shock absorbing unit, a driving unit and a visual unit. Multi-eye vision system for leading vehicles.

[0042] Four shock absorbing springs (3) are arranged coaxially and symmetrically between the top layer (4) of the shock absorbing unit and the bottom layer (2) of the shock absorbing unit, and the top layer (4) of the shock absorbing unit is welded coaxially to the fixing plate (5). The drive unit includes a hollow short shaft (12), a chassis (15) and an electric drive wheel (16), and the hollow short shaft (12) is coaxially assembled with the bottom layer of the damping unit (2) through a deep g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com