Novel thin compressive overtemperature protection element structure

An over-temperature protection, thin technology, used in electrical components, emergency protection devices, circuits, etc., can solve the problems of complex structure, poor rigidity, and the insulation area is not resistant to external pressure, and achieve the effect of strong pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

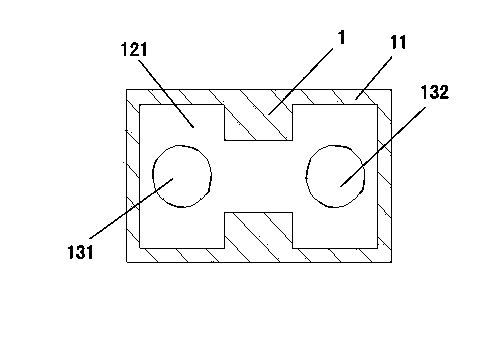

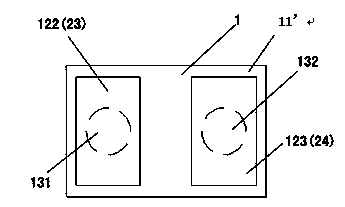

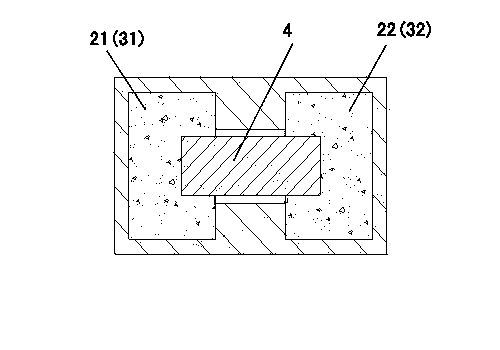

[0041] Such as figure 1 The top view of the insulation tank body of the present invention, figure 2 Bottom view of the insulation tank body of the present invention, image 3 As shown in the top view of the element structure of the present invention:

[0042] A new type of thin-type anti-pressure over-temperature protection element structure, including an insulating tank body and a metal area, and its operating temperature is set at 70 to 120 ° C, wherein:

[0043] The upper and lower surfaces of the insulating tank 1 are of symmetrical structure, with protrusions all around, and a low-lying area is formed in the middle, and two discontinuous metal areas are arranged in the low-lying area, and the upper surface is covered by a low-melting point alloy 4. The two upper left and upper right metal areas 21, 22 are connected;

[0044] A flux 5 is coated on the low melting point alloy 4;

[0045] There are left and right tin-plated layers 31, 32 on the left and right metal area...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that PEI (polyetherimide) is used for the insulating tank body 1 and the insulating cover 6, and the insulating tank body 1, the low melting point alloy 4, the flux 5, and the insulating cover 7 are made according to the embodiment. 1 way to arrange and weld, finished product (50pcs) after inspection.

Embodiment 3

[0060] The difference between this embodiment and the preceding embodiments is that PA (heat-resistant polyamide) is used for the insulating tank body 1 and the insulating cover 6, and the insulating tank body 1, the low-melting point alloy 4, the flux 5, and the insulating cover 7 are made according to the embodiment. 1 way to arrange and weld, finished product (50pcs) after inspection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com