A gas sampling and anti-blocking device in goaf of coal mine

A gas sampling and goaf technology, applied in sampling devices, measuring devices, sampling, etc., can solve the problems of crushing bundled tubes, small coal lumps entering the casing, high pressure, etc., and achieve the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

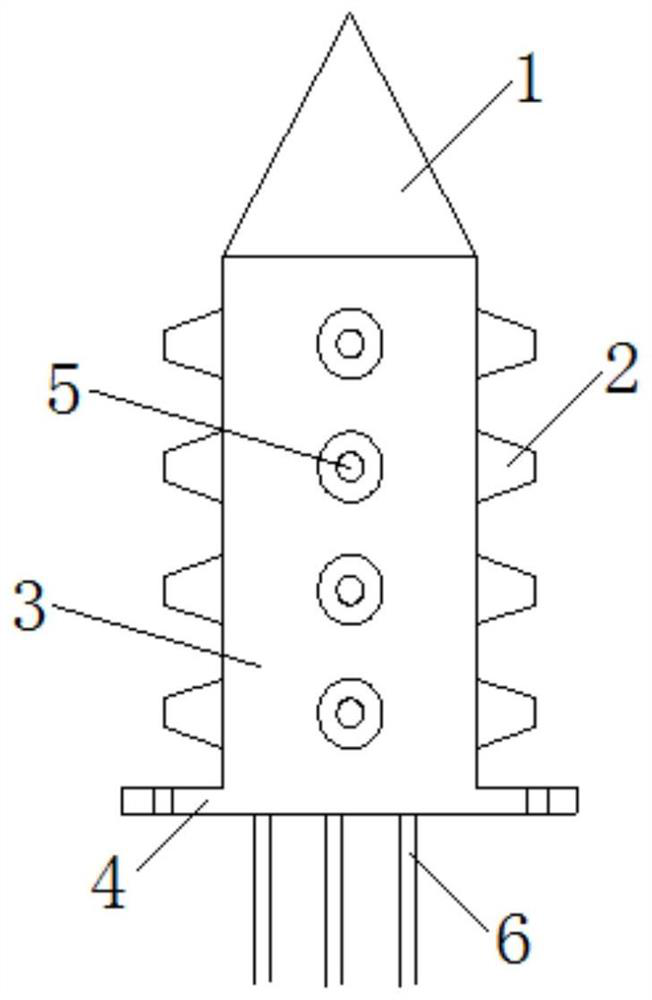

[0026] Embodiment 1: as figure 1 As shown, a coal mine goaf gas sampling anti-blocking device, including:

[0027] Rigid casing 3;

[0028] The pressure divider 1 is a cone structure, which is used to decompose the pressure directly above, reduce stress concentration and play a role in resisting pressure, and the bottom surface of the cone is fixedly connected to the top of the rigid sleeve 3;

[0029] A plurality of air intake elements 2, the air inlet 5 of each air intake element 2 is opposite to the side wall of the rigid sleeve 3, and each air intake element 2 is fixed on the side wall of the rigid sleeve 3 and rigid The inside of the sleeve 3 is connected, and the gas enters the inside of the rigid sleeve 3 from the air intake element 2 during pumping; the upper side of the air intake element 2 is inclined downward at an angle, and when the coal block falls from above, it will follow the slope. slide down.

[0030] The invention provides a gas sampling and anti-blockin...

Embodiment 2

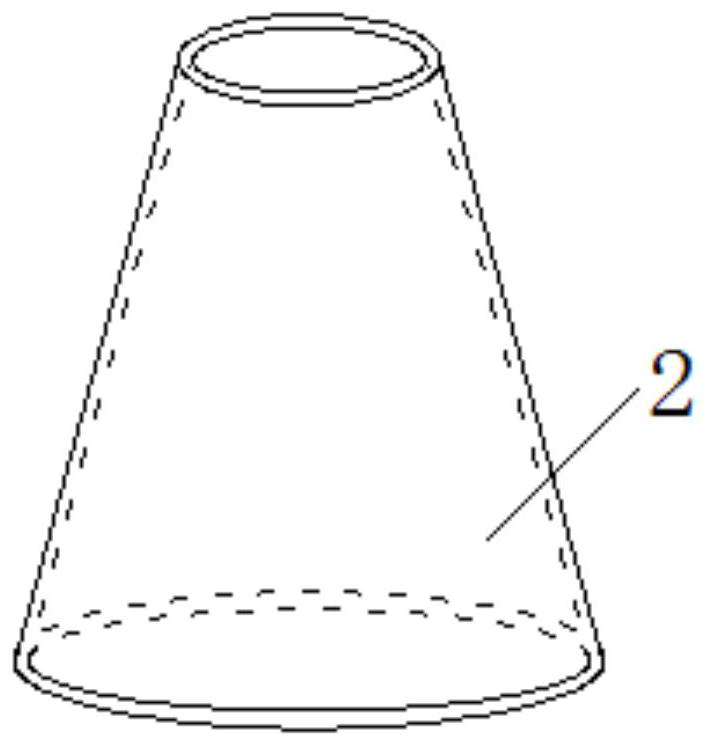

[0032] This embodiment is based on Embodiment 1, the air intake element 2 is a hollow circular frustum structure, the bottom end of the circular frustum is welded on the side wall of the rigid sleeve 3, the top of the circular frustum is far away from the rigid sleeve 3, and the circular frustum The axis is perpendicular to the axis of the rigid sleeve 3, the side of the truncated cone is a conical slope, and the axis of the conical slope is perpendicular to the axis of the rigid sleeve 3.

[0033] In the present invention, the intake element 2 is a hollow circular frustum structure, the diameter of the bottom end of the circular frustum is greater than the diameter of the top end of the circular frustum, the side of the circular frustum is a conical inclined surface, the axis of the conical inclined surface is perpendicular to the axis of the rigid sleeve, and vertical Extend outward, and at the same time, the air inlet of the round platform is opposite to the side wall of the...

Embodiment 3

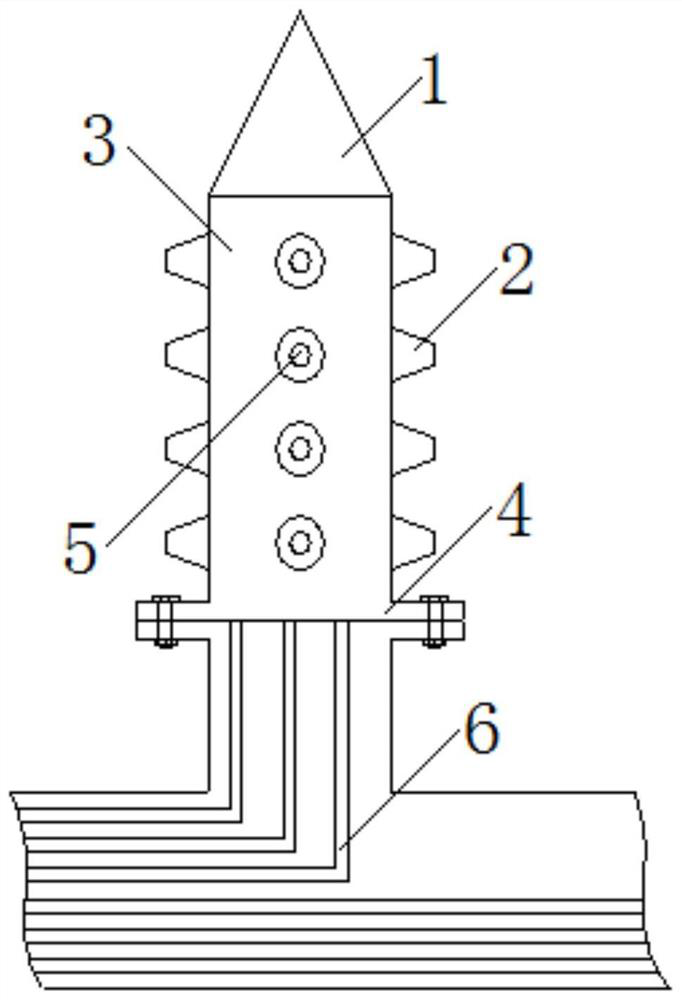

[0035] This embodiment is based on embodiment 1, as attached Figure 4 As shown, the pressure divider 1 is a cone structure, which is used to decompose the pressure directly above, reduce stress concentration and play a role in resisting pressure, and the bottom surface of the cone is fixedly connected with the top end of the rigid sleeve 3, and the cone The body structure can decompose the vertical downward pressure into the pressure parallel to the cone surface and the pressure perpendicular to the cone surface.

[0036] In the present invention, the pressure divider 1 is a cone structure, and the force perpendicular to the pressure divider 1 is decomposed into the pressure P1 parallel to the cone surface and the pressure P2 perpendicular to the cone surface through the pressure divider 1, and only the pressure P2 acts On the partial pressure head, it plays the role of anti-pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com