Stator for rotating electrical machine

A technology for rotating electrical machines and stators, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problem of inability to cool the ends of the coils, and achieve the effect of improving the cooling effect and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

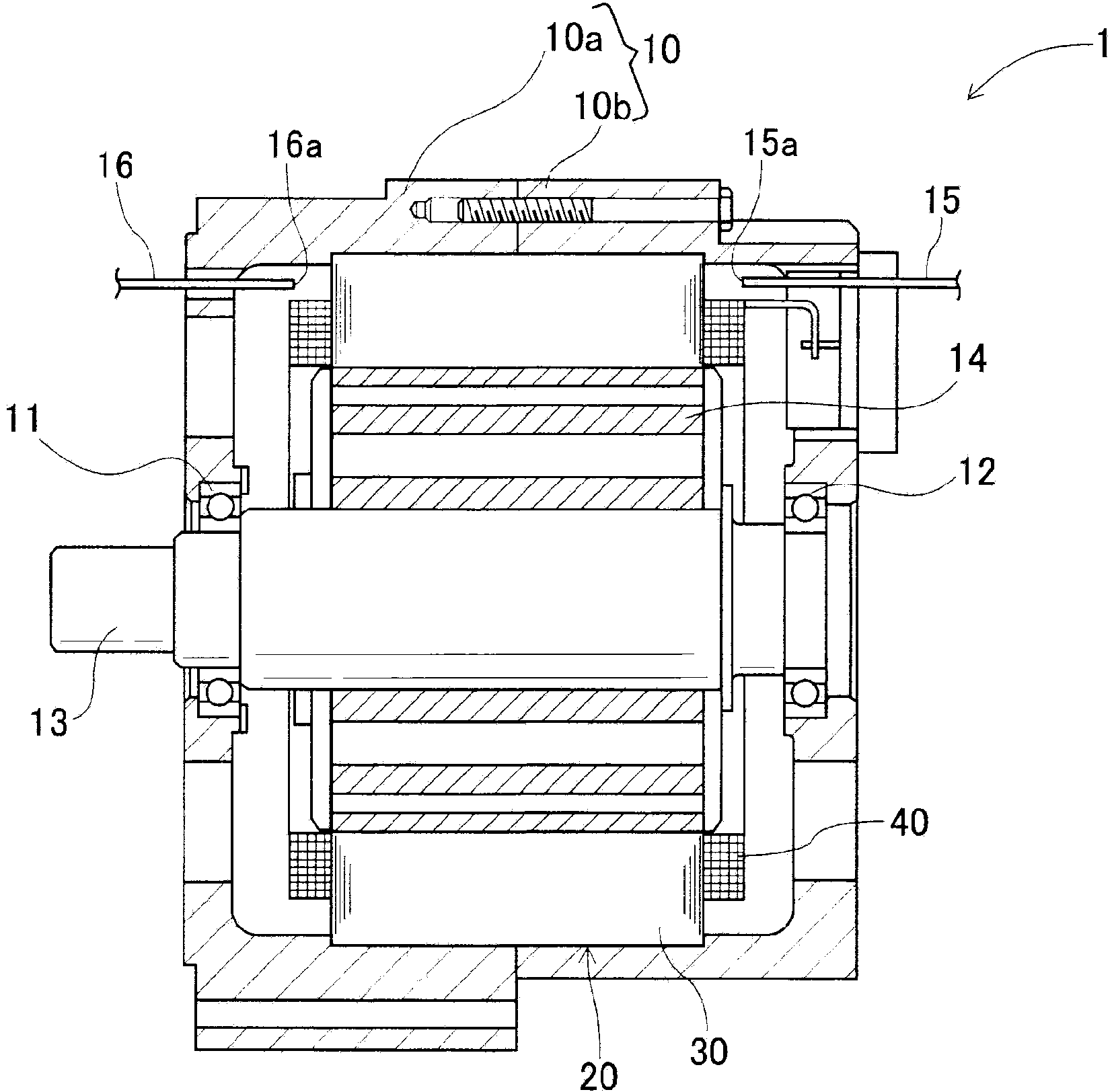

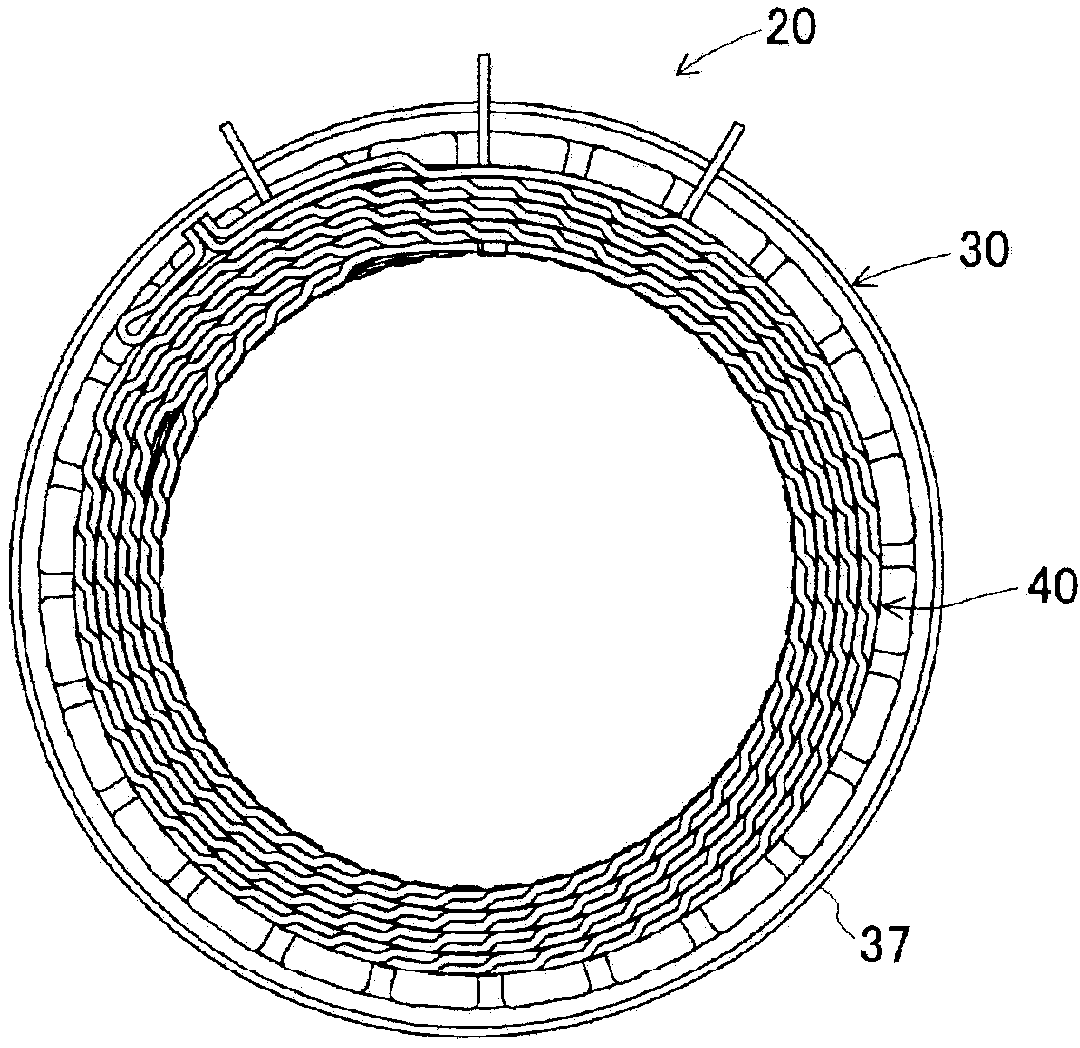

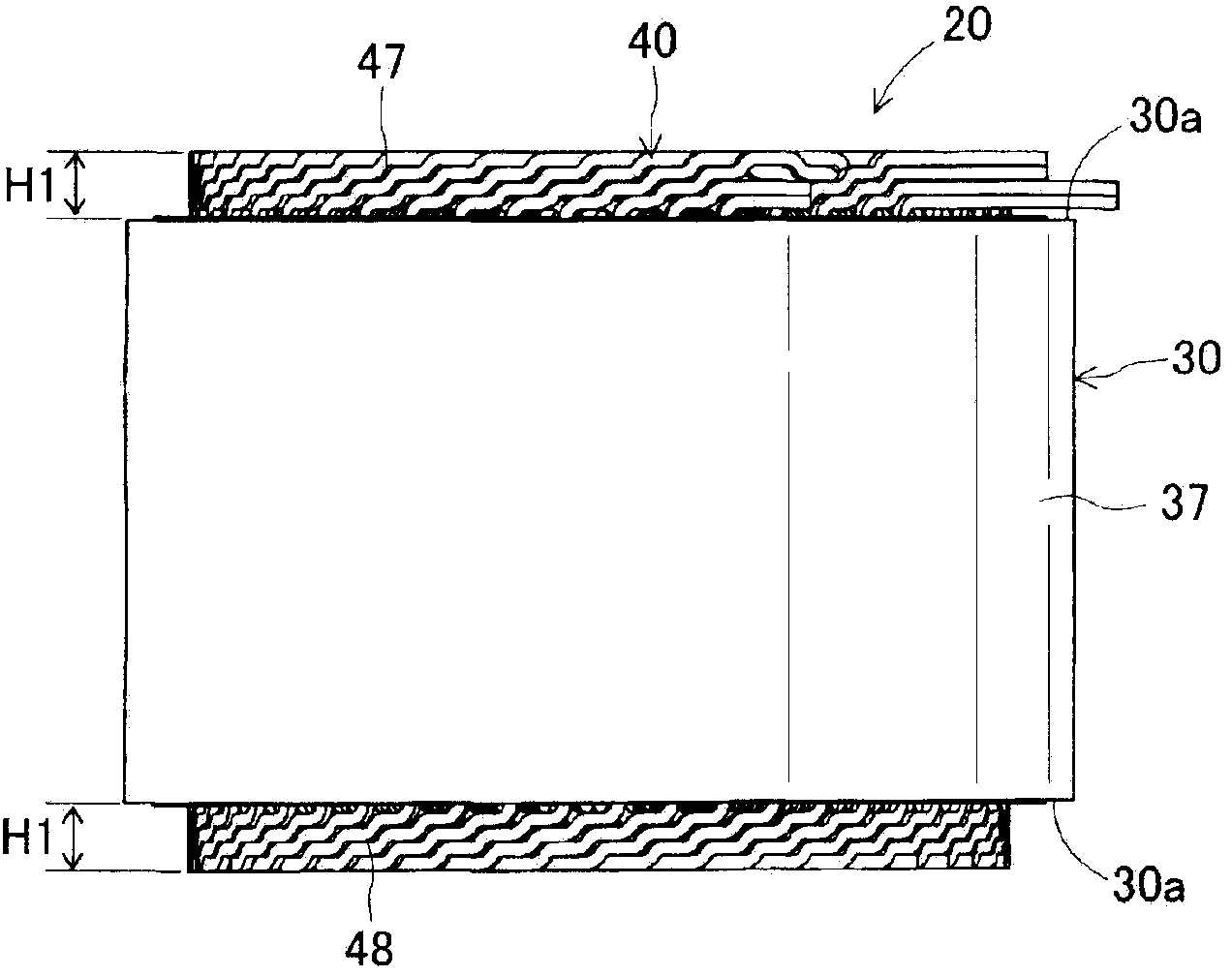

[0058] The stator of the present embodiment is mounted on a rotating electrical machine used as a vehicle generator. figure 1 It is an axial cross-sectional view schematically showing the structure of a rotating electrical machine equipped with a stator according to the present embodiment. like figure 1 As shown, the rotating electric machine 1 of the present embodiment includes a housing 10 formed by joining a pair of substantially bottomed cylindrical housing members 10A and 10B at openings, and is supported on the housing 10 via bearings 11 and 12 . A rotatable rotary shaft 13 , a rotor 14 fixed to the rotary shaft 13 , and a stator 20 fixed to the casing 10 surround the rotor 14 within the casing 10 .

[0059] In addition, the rotary electric machine 1 is provided with a refrigerant supply unit including a pair of refrigerant pipes 15 and 16 for supplying a cooling medium for cooling to the stator winding 40 of the stator 20 . Refrigerant lines 15 and 16 communicate betw...

Embodiment approach 2

[0094] Figure 11 It is a perspective view seen from the conductor segment insertion side of the stator of Embodiment 2. Figure 12 It is a perspective view seen from the conductor segment welding side of the stator of Embodiment 2. Figure 13 It is explanatory drawing which shows the state which inserted the conductor segment into the slot of the stator core in Embodiment 2.

[0095] The stator 120 of this embodiment is the same as that of the first embodiment, and is also mounted on the rotary electric machine 1 used as a power generator for a vehicle. Figure 11 ~ Figure 13 As shown, the difference between the stator winding 140 and the first embodiment is that a plurality of substantially U-shaped conductor segments 150 are assembled in the stator core 130 and then connected in a predetermined state.

[0096] The stator 120 of the present embodiment includes an annular stator core 130 and a stator winding 140 formed by combining a pair of linear portions, a turning porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com