Dry fermentation device for processing tea

A dry fermentation device and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of low heat, uneven heating fermentation degree, difference in fermentation effect, etc., and achieve good fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

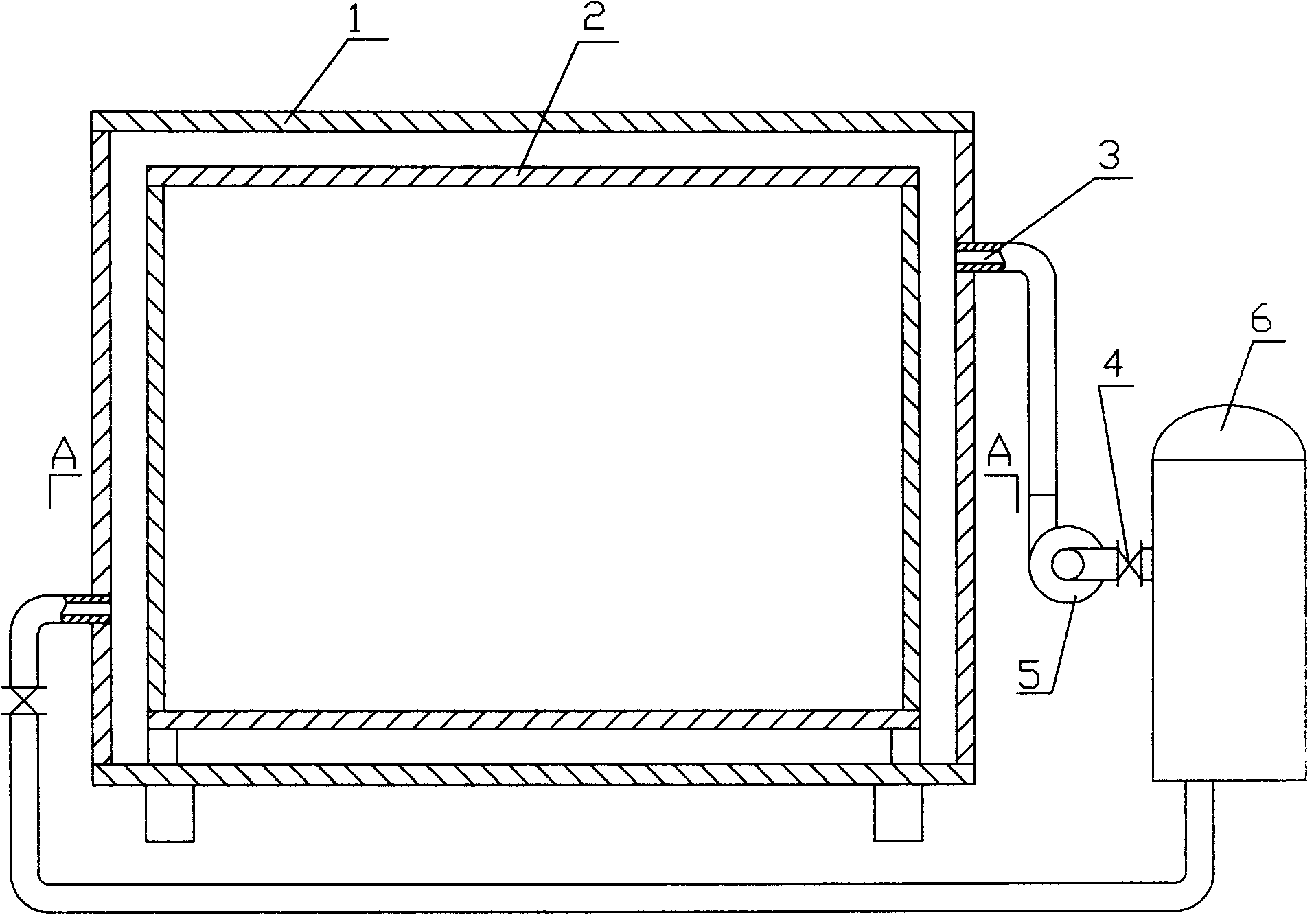

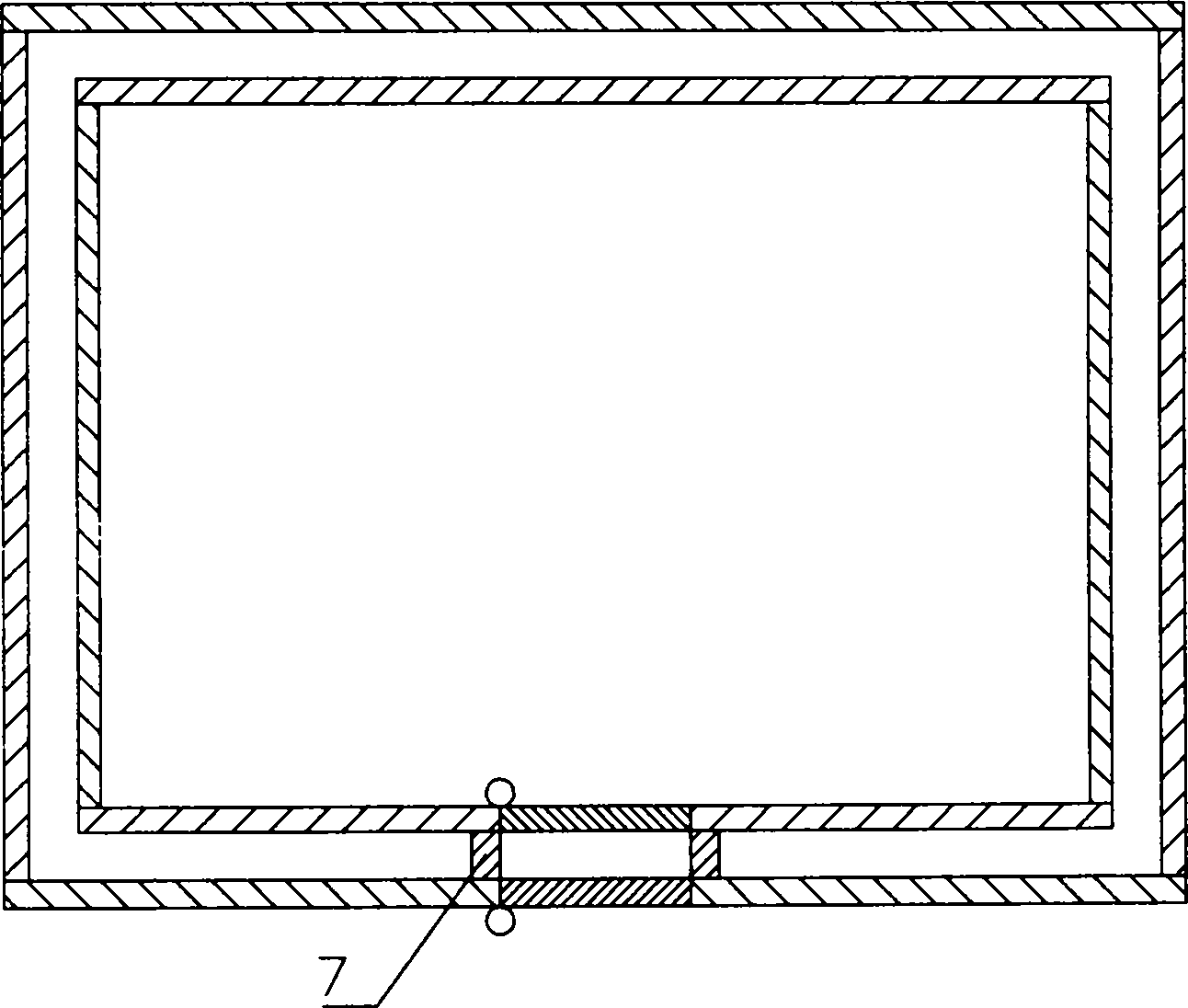

[0010] The invention includes a base and a base shell box-shaped body 1, and is characterized in that: a pine inner box-shaped body 2 is arranged in the inner cavity of the base shell box-shaped body 1, and the pine wood inner box-shaped body 2 is spliced by several pine wood laths and is provided with a door frame, a pulley Door structure, the underframe of the pine inner box-shaped body 2 is fixed on the base plate of the base shell box-shaped body 1, and the wall panels corresponding to the pine inner box-shaped body 2 and the base shell box-shaped body 1 keep a distance. A rectangular pine plank frame 7 with a rectangular longitudinal section is docked and fixed between the door frames of the shell box body 1 to implement a sealed and fixed connection between the two; the side wall of the base shell box body 1 is provided with a steam inlet 3, and the steam inlet 3 is connected with the exhaust port of the fan 5 through the pipeline, the air inlet of the fan 5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com