Mud weighting process and special equipment

A special device and slurry technology, applied in transportation and packaging, mixer, dissolving and other directions, can solve the problems of high labor intensity, endanger human health, dust pollution of the environment, etc., to reduce labor intensity, improve efficiency, and solve the problem of polluting the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

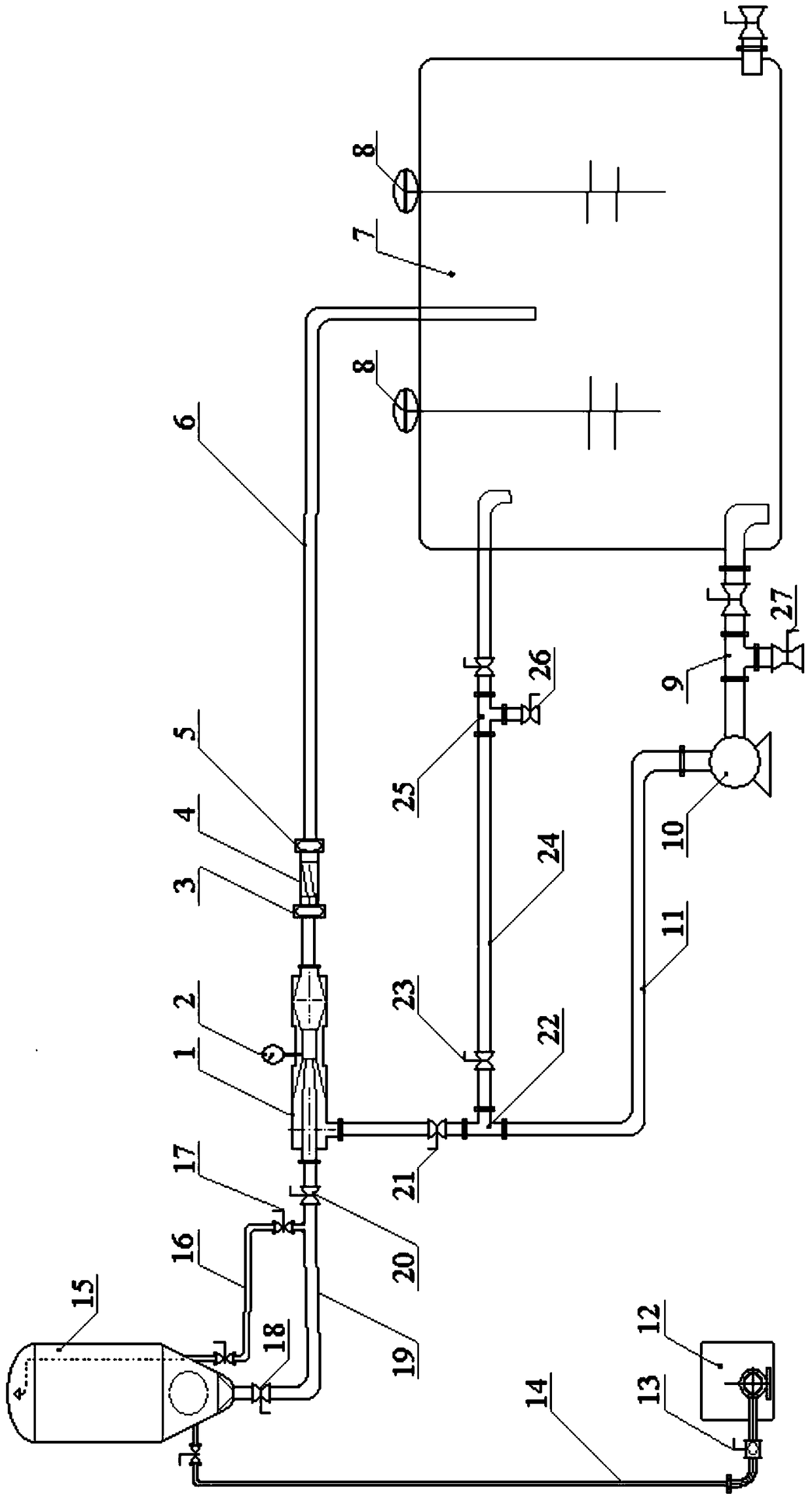

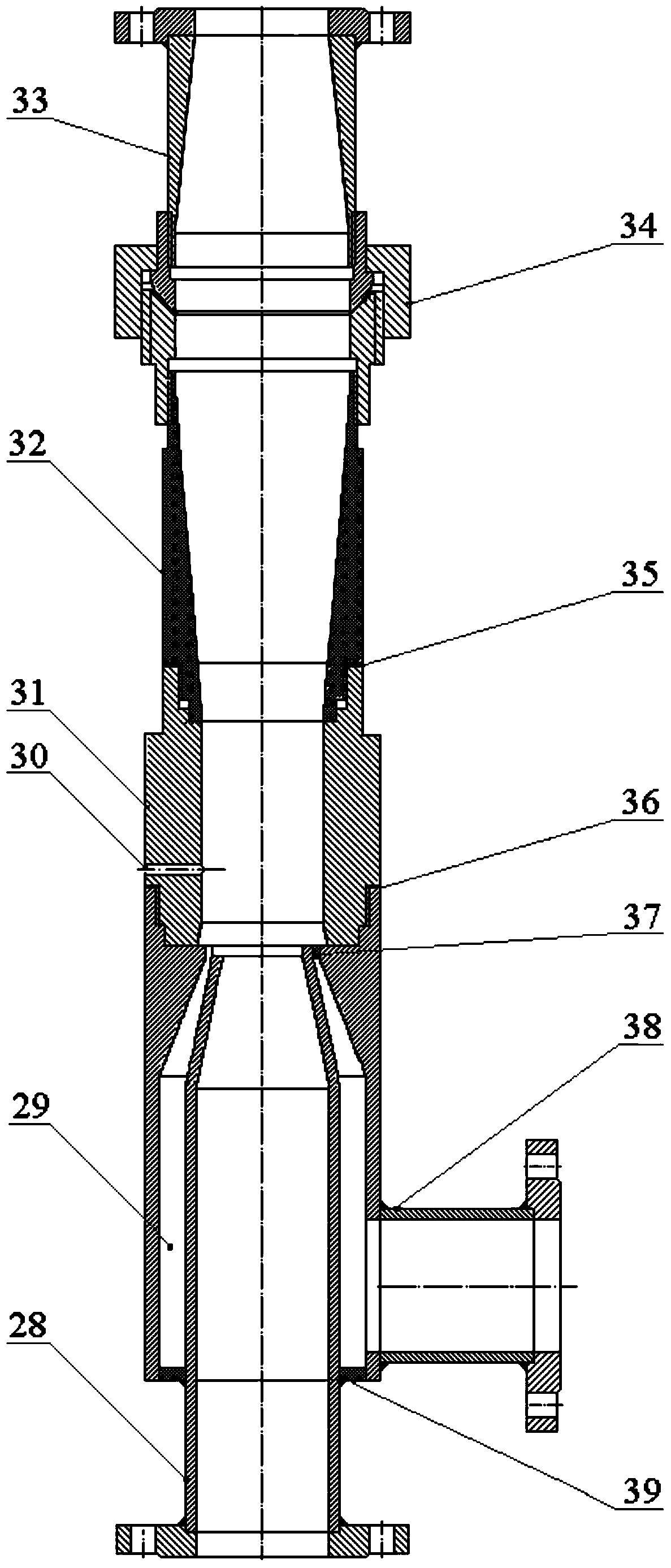

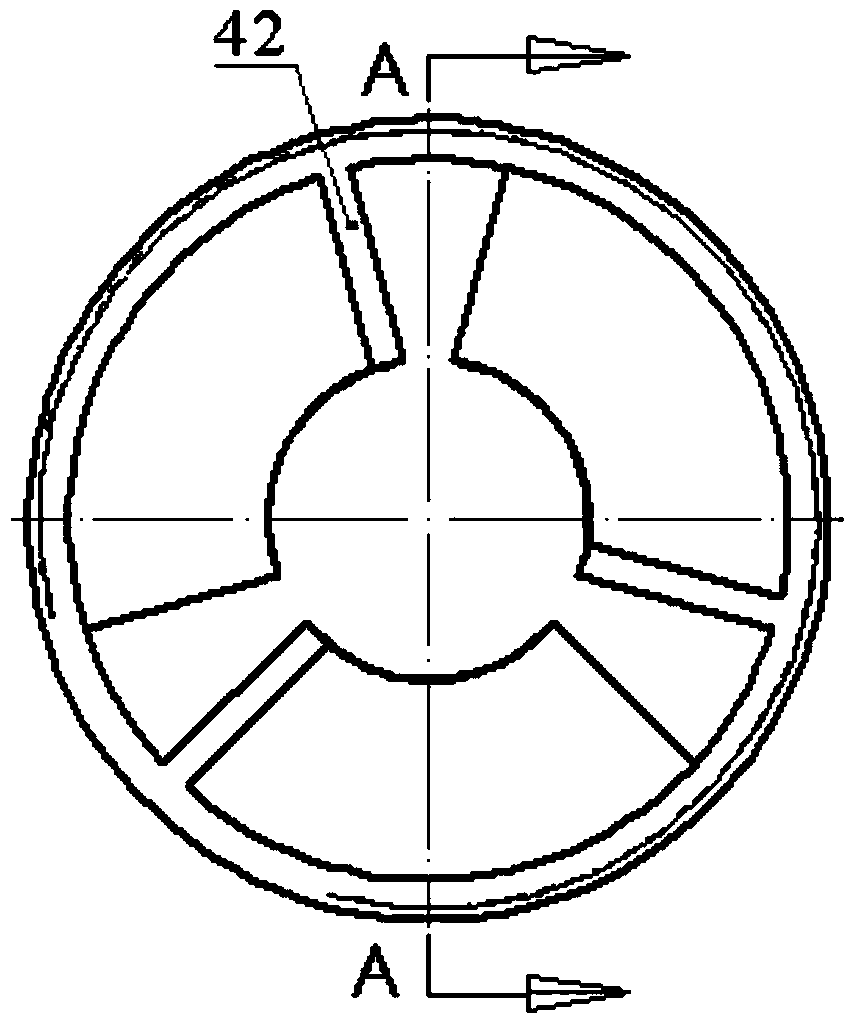

[0012] refer to figure 1 , figure 2 , the present invention is made up of mud pool 7, sand pump 10, air compressor 12, stone powder tank 15, stone powder mixing pump 1, stone powder mixing pump 1 is a tubular body combined structure, and one end is two inlets that cross vertically, wherein, the vertical inlet It is connected to the mud pool 7 through the heavy slurry valve 21, the slurry supply pipeline 11, and the sand pump 10, and the horizontal inlet is connected to the stone powder tank 15 through the powder inlet valve 20 and the stone powder pipeline 19; the other end of the stone powder mixing pump 1 is connected to the The mud pool 7 ; the stone powder tank 15 is connected with the air compressor 12 through the air supply pipeline 14 and the air source valve 13 .

[0013] The vertical inlet of the stone powder mixing pump 1 is provided with a circulation tee 22 on the slurry supply line 11 between the heavy slurry valve 21 and the sand pump 10, which can be connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com