Flux cored wire forming machine

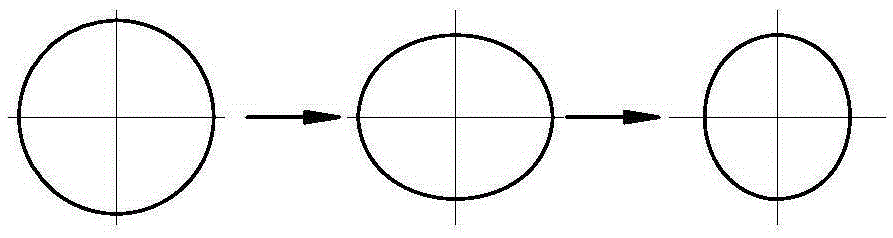

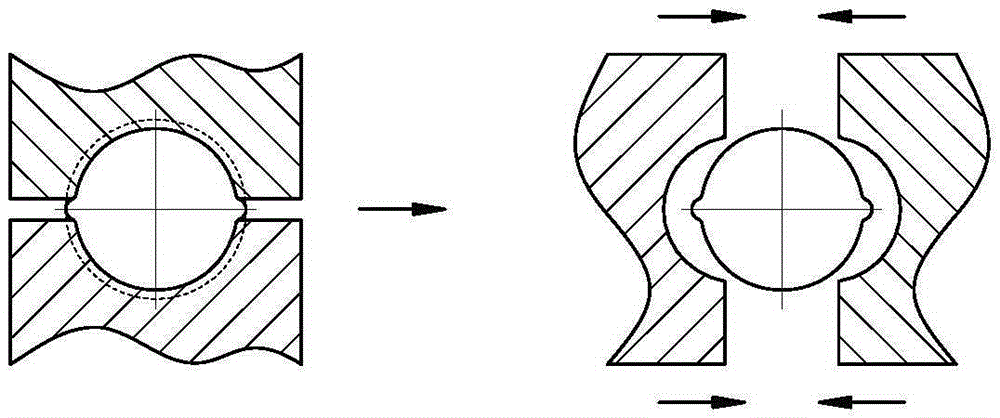

A technology of flux-cored welding wire and forming machine, which is applied in the direction of wire drawing dies, etc., can solve the problems of wearing the surface of flux-cored welding wire, increasing the resistance of diameter reduction, etc., and achieves the effect of saving finishing drawing, eliminating sliding friction and reducing dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

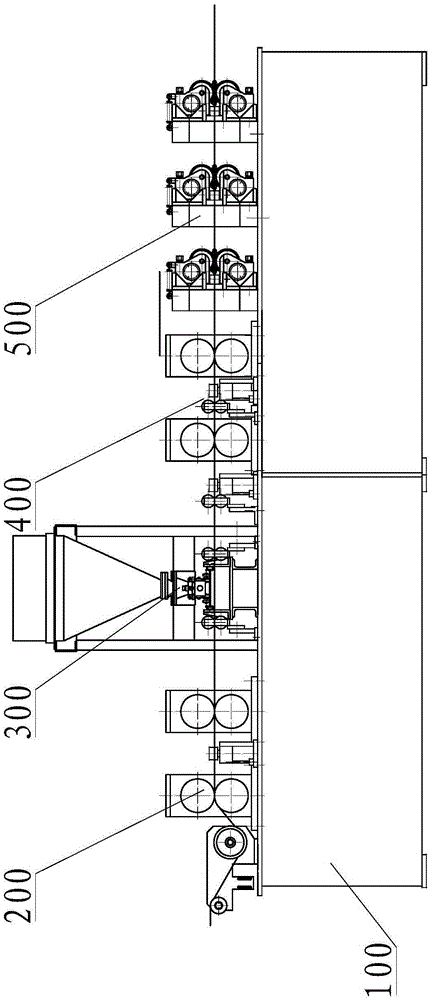

[0052] Such as image 3 with Figure 4 As shown, a flux-cored welding wire forming machine includes a base 100, on which a forming rolling stand 200, a powder feeder 300, a closing rolling stand 400 and a diameter reducing device are sequentially arranged from upstream to downstream. In this embodiment, Described reducing device is 3 active roll molds 500, and described active roll mold comprises at least one pair of passive rolls, and the axis of rotation of every pair of passive rolls is parallel to each other, also includes at least one pair of active rolls, and the rotation of every pair of active rolls The axes are parallel to each other, at least one active roll in each pair of active rolls is connected to the driving device through the transmission device or directly connected to the driving device, the rotation axes of all the active rolls and the passive rolls are in the same plane, and the plane is perpendicular to the flux cored wire . image 3 The figure only sho...

Embodiment 2

[0054] Such as Figure 5 with Image 6 As shown, a flux-cored welding wire forming machine includes a base 100, on which a forming rolling stand 200, a powder feeder 300, a closing rolling stand 400 and a diameter reducing device are sequentially arranged from upstream to downstream. In this embodiment, The diameter reducing device is a set of active roll dies 500, a set of passive roll dies 600 and a set of active roll dies arranged in sequence. The active roll dies include at least one pair of passive rolls, and the axes of rotation of each pair of passive rolls are parallel to each other. , also includes at least one pair of driving rolls, the rotation axes of each pair of driving rolls are parallel to each other, at least one driving roll in each pair of driving rolls is connected to the driving device through a transmission device or directly connected to the driving device, all the driving rolls and passive rolls The axis of rotation is in the same plane, and the plane ...

Embodiment 3

[0059] see Figure 7 to Figure 10 ,

[0060] A driving roll mold, comprising at least one pair of passive rolls, the rotation axes of each pair of passive rolls are parallel to each other, and at least one pair of driving rolls, the rotation axes of each pair of driving rolls are parallel to each other, at least one of each pair of driving rolls The driving rolls are connected to the driving device through the transmission device or directly connected to the driving device, and the rotation axes of all the driving rolls and the passive rolls are in the same plane, and the plane is perpendicular to the flux cored wire.

[0061] Specifically:

[0062] The driving roll 2 is installed on the roll shaft 24 through the rolling bearing 8, and the roll shaft is installed on the driving roll frame 11, and the driving roll frame is also provided with a driving gear shaft 1, and the driving gear shaft is installed on the driving roll bracket through the rolling bearing. A single-input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com