Handheld drilling machine with dust removal device

A dust removal device and drilling machine technology, which is applied to portable drilling machines, dust removal, drilling/drilling equipment, etc., can solve problems such as jumping and affecting the use effect, and achieve low cost, thorough dust removal, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

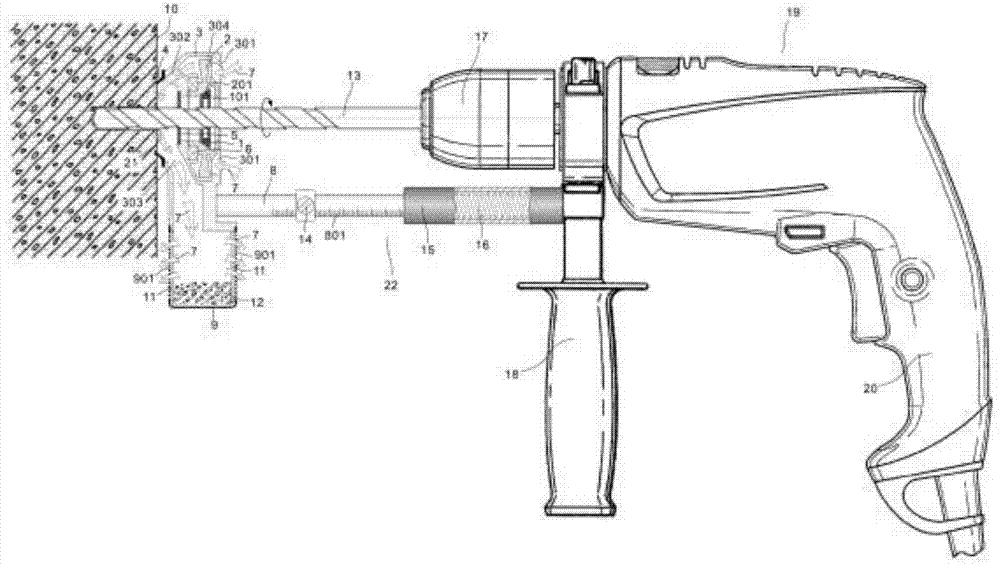

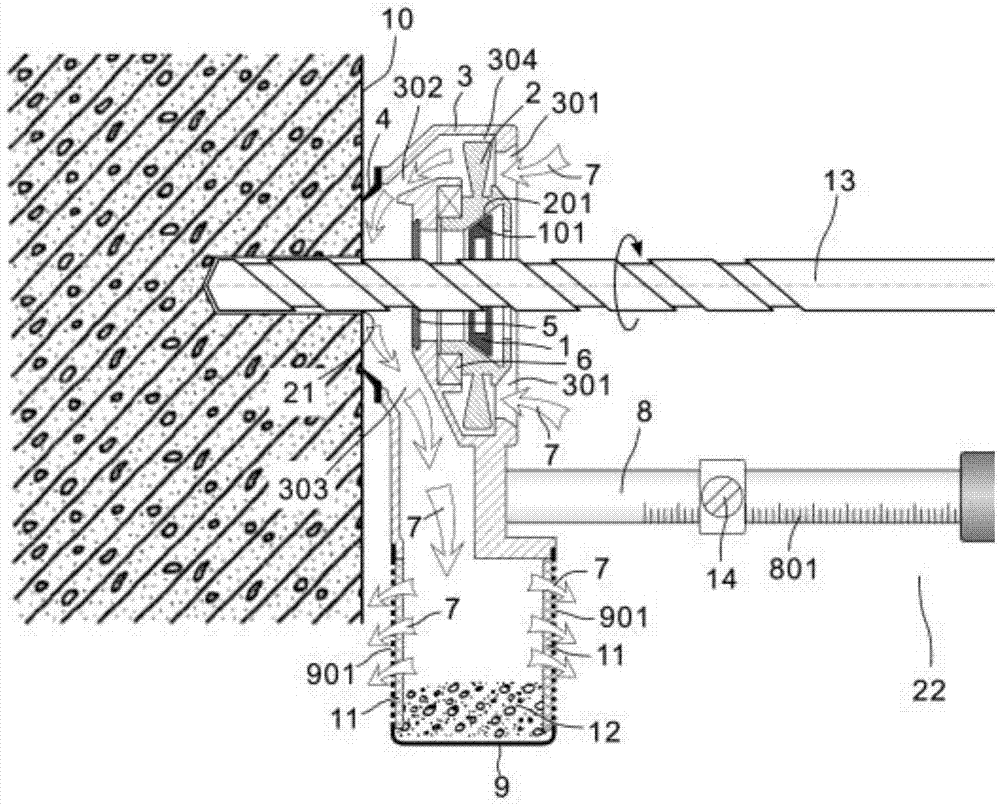

[0044] The first embodiment of the hand-held drilling machine with dust removal device of the present invention is as follows: figure 1 Shown, comprise drilling machine housing 19, drill chuck 17, drill bit 13, auxiliary handle 18 and telescoping tube 22; The interior of drilling machine housing 19 is equipped with motor, and its rear part is main handle 20; Drill chuck 17 is located at the front of the drilling machine housing 19 and is driven by a motor, which is used to clamp the drill bit 13 for drilling operations; the auxiliary handle 18 is installed on the drilling machine housing 19, and the auxiliary handle 18 is close to the drill chuck 17; One end of telescopic tube 22 is connected on the housing of dust collecting seat 3, and the other end of telescopic tube 22 is installed on the auxiliary handle 18; A spring 16 is provided inside, and a scale mark 801 and a positioning block 14 are provided on the inner telescopic tube 8 , and the depth of the drill hole drilled ...

Embodiment 2

[0054] Figure 8 It is a structural schematic diagram of the second embodiment of the hand-held drilling machine with dust removal device of the present invention, as Figure 8 As shown, the difference between the second embodiment of the present invention and the first embodiment is that one end of the telescopic tube 22 is connected to the dust collecting seat 3, and the other end of the telescopic tube 22 is installed on the drilling machine housing 19 superior.

Embodiment 3

[0056] Figure 9 It is a structural schematic diagram of the third embodiment of the hand-held drilling machine with dust removal device in the present invention, Figure 10 It is a structural schematic diagram of the dust removal device of the third embodiment. Such as Figure 9 and Figure 10 As shown, the difference between the third embodiment of the present invention and the first embodiment is that the air inlet is changed to an air outlet 305, and the air outlet 305 is arranged on the housing of the dust collecting seat 3; The wind flow direction 7 is opposite to that of the first embodiment, the air suction port 306 is located at the front end of the dust collecting seat 3, and the lower air channel 303 starts from the hole 21 when the drill bit is working, extends downward and communicates with the air chamber 304, and the wind flow As shown in the wind flow direction 7, it enters the orifice 21 from the air suction port 306, and then enters the air chamber 304 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com