Ultrahigh water material composite solid waste pulping, delivering and mixing device

A solid waste and mixing device technology, which is applied in solid waste management, clay preparation devices, safety devices, etc., can solve the problems of restricting the development of filling and mining technology, the impact of mining and filling technology, and low filling efficiency, and achieve a high degree of automation , good fluidity and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

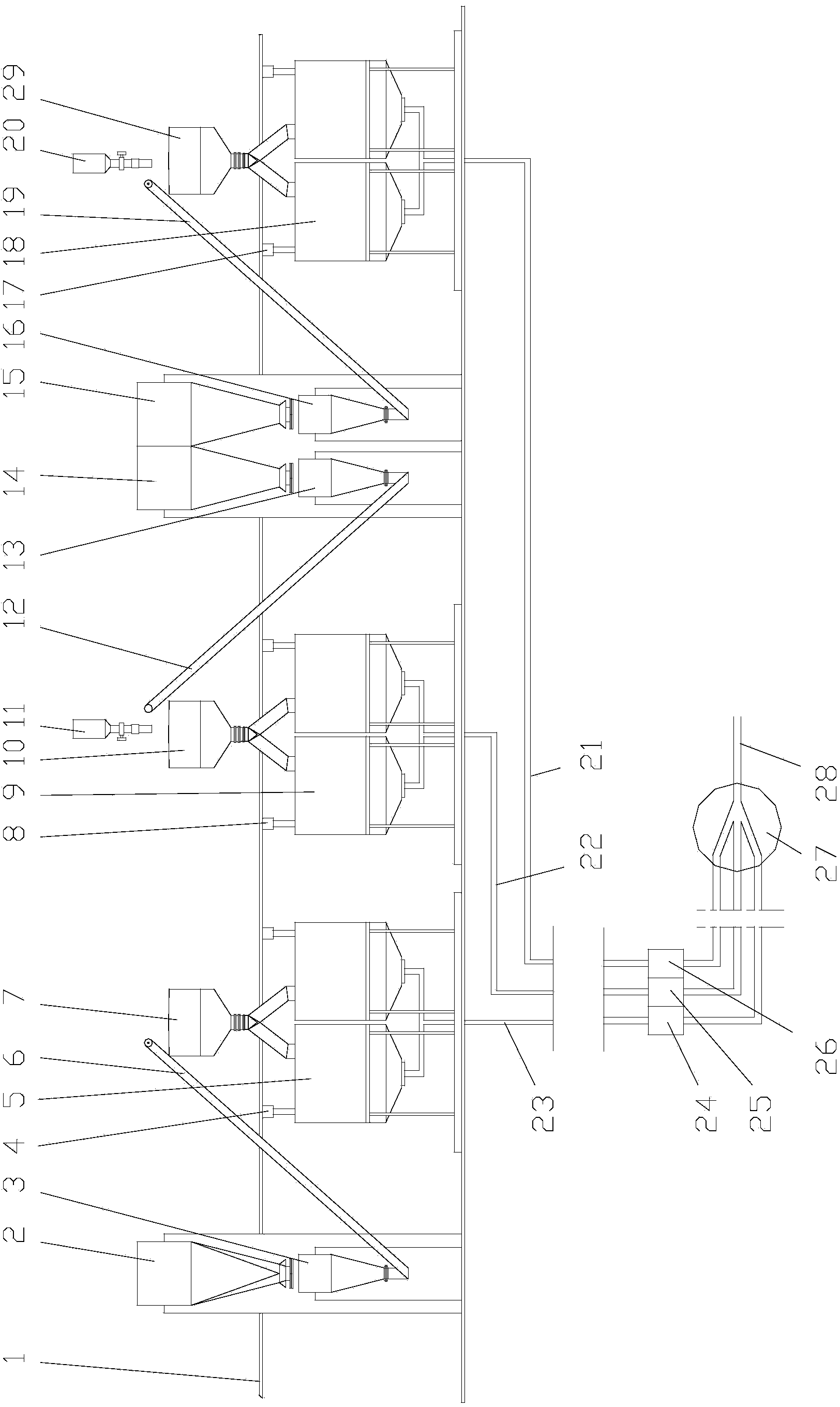

[0012] Ultra-high water materials refer to hydraulic materials with a water volume ratio of up to 95-97% (water-cement ratio about 6.5:1-11:1). The main material of the material consists of two main materials A and B and two auxiliary materials A-A and B-B, a total of 4 components. When the ultra-high water filling material is used, A and A-A materials, B and B-B materials are mixed with water to form A slurry and B slurry, which are transported independently through pipelines, mixed near the filling site, and then transported to the use site. After the ultra-high water material A and B slurries are fully mixed, they can be consolidated in a short period of time (10-90min) to form a consolidated body mainly composed of ettringite.

[0013] The main purpose of the present invention is to add solid waste to the greatest extent when using ultra-high water materials to fill gobs, make full use of waste, reduce the usage of ultra-high water materials to reduce filling costs.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com