Hip joint spacer mold

A technology for a placeholder and a hip joint is applied in the field of molds used for making hip joint placeholders, which can solve problems such as inability to change the molding ability, and achieve the effects of multiple operation possibilities, good surgical results, and economic burden reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

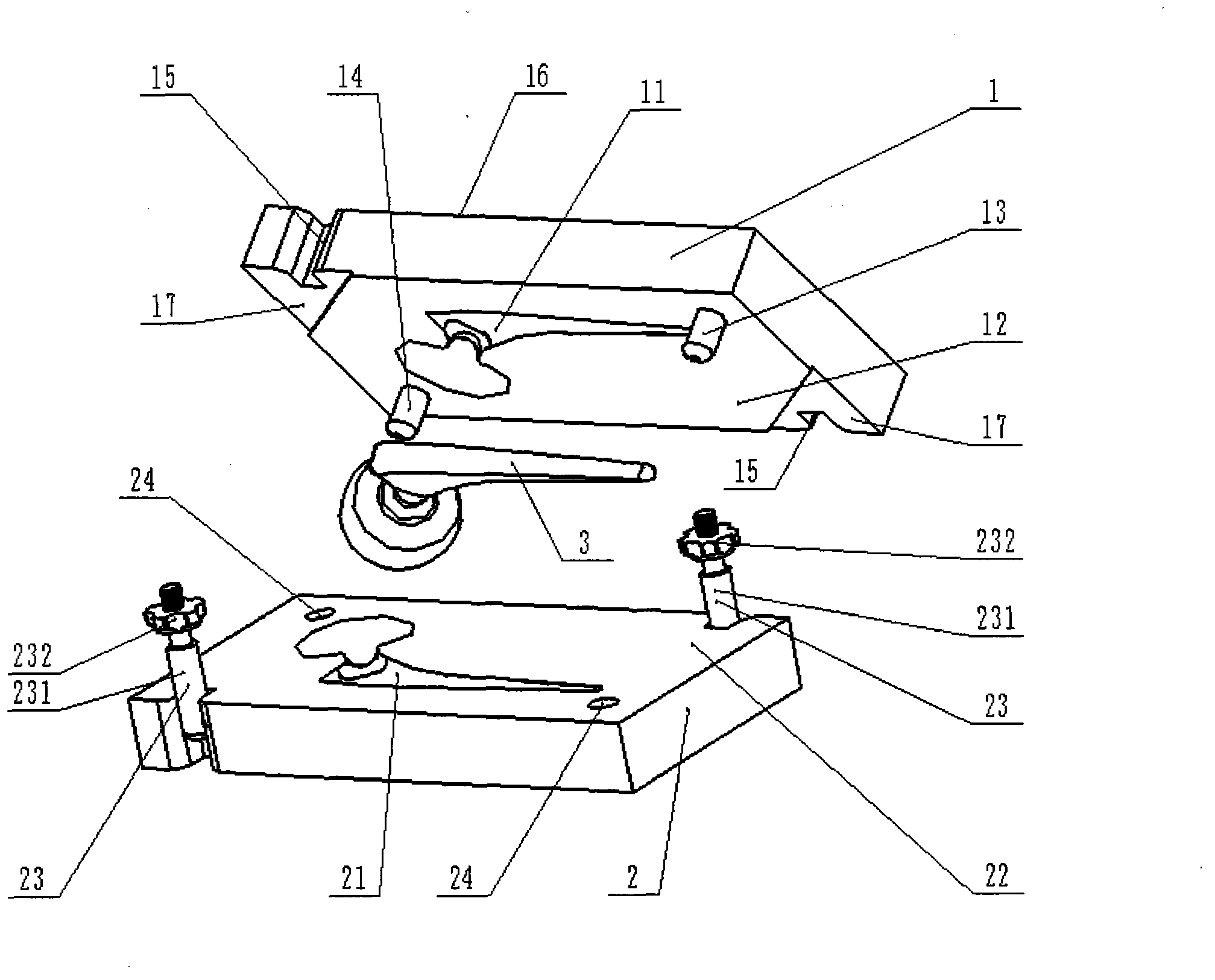

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

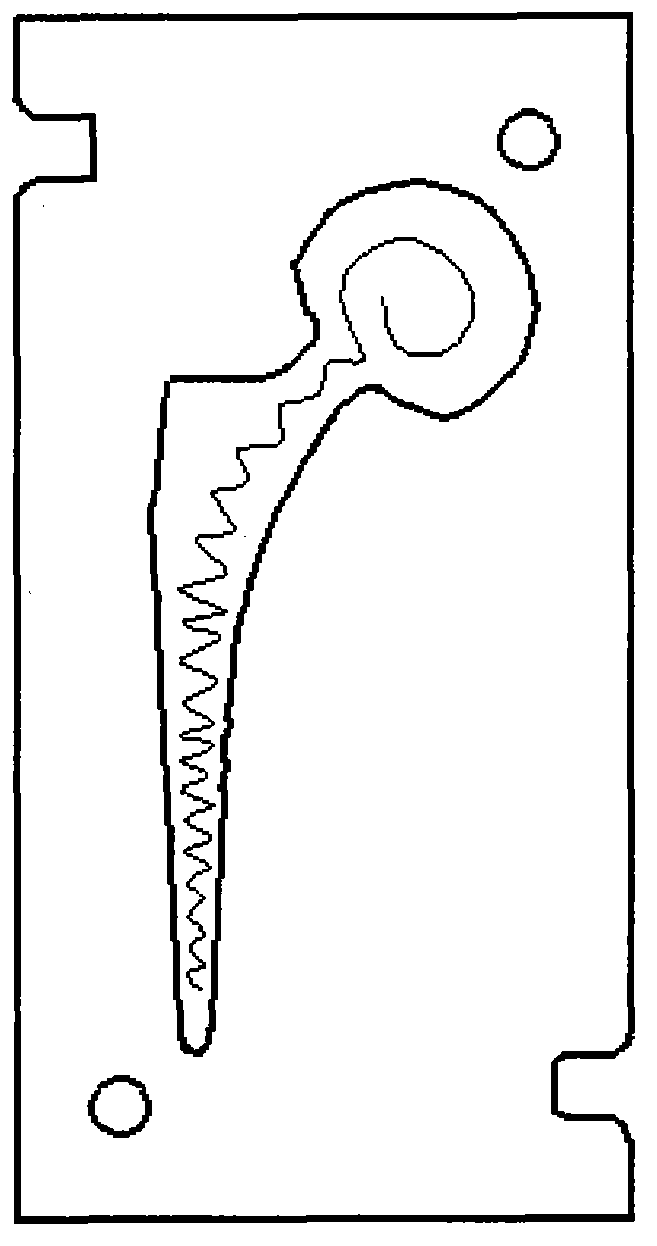

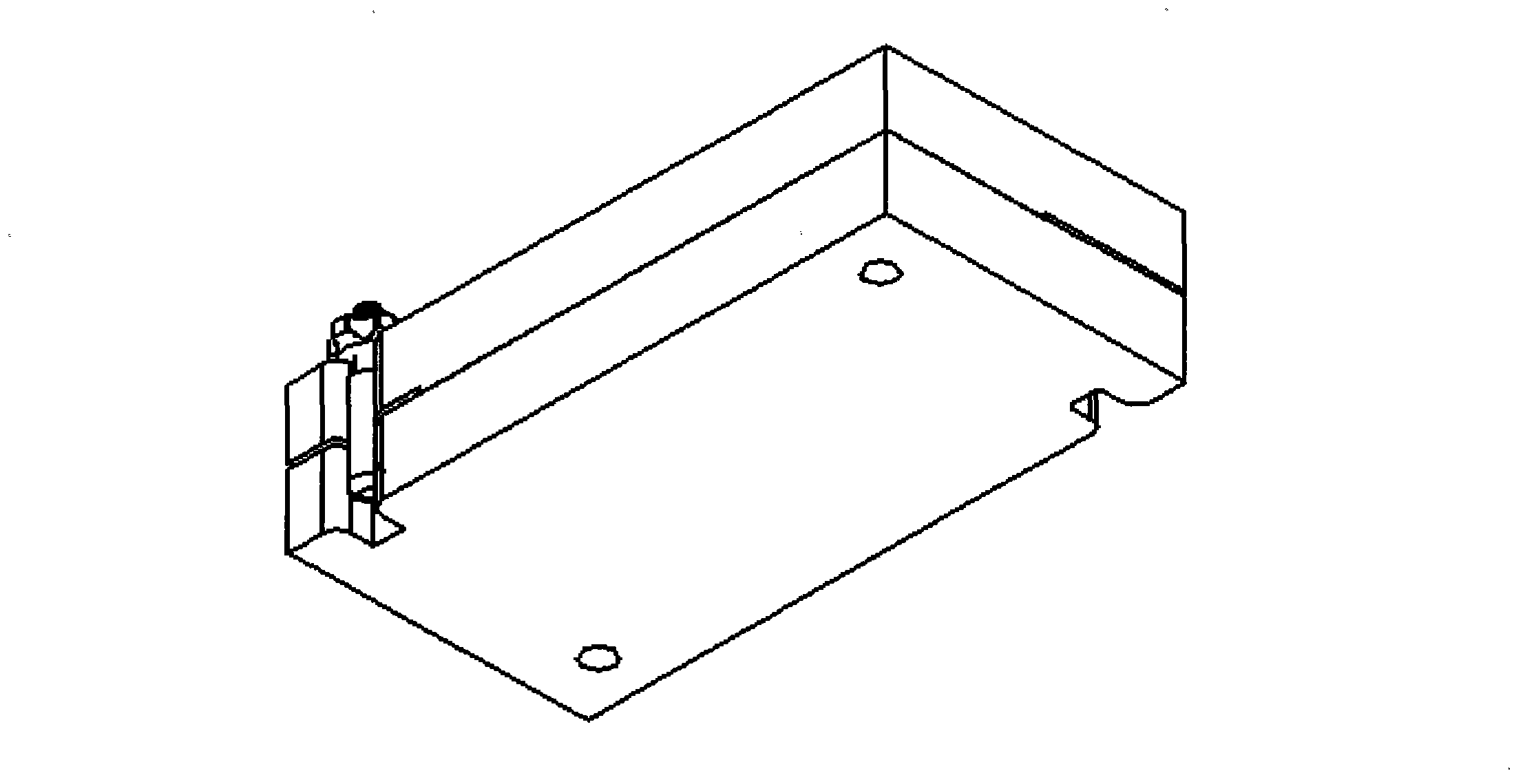

[0021] like figure 1 As shown, the present invention is made up of upper mold part 1 and lower mold assembly 2, and upper mold assembly and lower mold assembly all have a cavity feature 11 and 21 that are symmetrical to each other along the upper and lower mold interface respectively, when upper and lower mold assembly After the parts are fastened together, a closed cavity in the shape of the hemiprosthesis will be formed, and the shape of the cavity is consistent with the hip joint spacer 3, and is used to form the hip joint bone cement spacer 3;

[0022] During the manufacturing process of the spacer, first, bone cement containing antibiotics needs to be injected into the cavities of the upper and lower molds respectively, and after curing, the hip joint spacer 3 is formed. The hip joint spacer 3 is made in a sterile environment during the operation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com